A kind of cohesion-enhanced butyl rubber hot-melt pressure-sensitive adhesive and preparation method thereof

A technology of hot-melt pressure-sensitive adhesive and butyl rubber, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor bonding strength, inability to peel and rebond, etc., and achieve increased Cohesive strength, favorable coating adhesion processing, excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

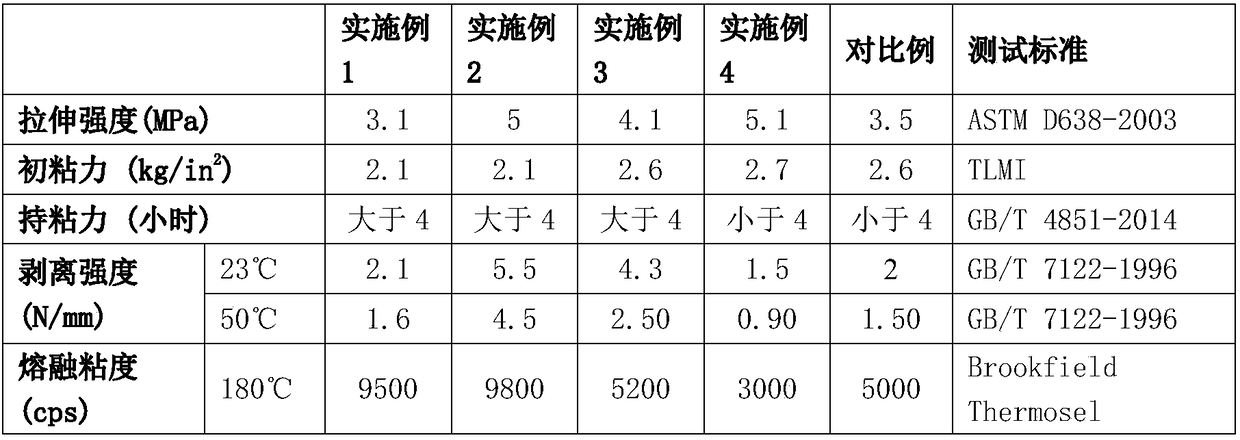

Examples

Embodiment 1

[0027] A cohesive reinforced butyl rubber hot-melt pressure-sensitive adhesive, the components and parts by weight are: butyl rubber 10%, bromobutyl rubber 9%, polyisobutylene resin with a molecular weight of 40,000 5%, N-vinyl Imidazole 0.8%, hydrogenated C5 petroleum resin 20%, 2000 low molecular weight polyisobutylene oil 10%, kaolin 45%, 1076 antioxidant 0.2%;

[0028] First, the bromobutyl rubber and butyl rubber were separately kneaded on the open mill; then the kneaded bromobutyl rubber and N-vinylimidazole were added to the kneader at 190 °C; after kneading for 5 minutes, the open kneader was added After kneading for 5 minutes, add plasticizer polyisobutylene oil mixed with antioxidant 1076 and hydrogenated C5 petroleum resin; finally add kaolin, mix under vacuum for 2 hours and then discharge.

Embodiment 2

[0030] A cohesive reinforced butyl rubber hot-melt pressure-sensitive adhesive, the components and parts by weight are: butyl rubber 17%, bromobutyl rubber 10%, SIS resin 10%, 2-ethylimidazole 0.5%, Terpene resin 18%, white oil 15%, calcium carbonate 29%, antioxidant 1010, 168 0.25% each;

[0031] First, the bromobutyl rubber and butyl rubber were separately kneaded on the open mill; then the kneaded bromobutyl rubber and 2-ethylimidazole were added to the kneader at 180 °C; after kneading for 10 minutes, the open kneader was added After kneading for 2 minutes, add plasticizer white oil and terpene resin mixed with antioxidants 1010 and 168; finally add calcium carbonate, mix under vacuum for 1 hour and then discharge.

Embodiment 3

[0033] A cohesive reinforced butyl rubber hot-melt pressure-sensitive adhesive, the components and parts by weight are: butyl rubber 19%, bromobutyl rubber 13%, SBS resin 3%, 2-ethylimidazole 0.1%, Hydrogenated C5 petroleum resin 24%, naphthenic oil 20%, calcium carbonate 10.5%, silica 10%, antioxidant 1010, 168 0.2% each;

[0034] First, the bromobutyl rubber and butyl rubber were separately kneaded on the open mill; then the kneaded bromobutyl rubber and 2-ethylimidazole were added to the kneader at 170 °C; after 10 minutes of kneading, the open kneading was added After kneading for 3 minutes, add plasticizer naphthenic oil and hydrogenated C5 petroleum resin mixed with antioxidants 1010 and 168; finally add calcium carbonate and silica, and mix under vacuum for 1 hour Discharge later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com