High-throughput chemical vapor infiltration process based on parameter region control, application thereof and device adopting same

A technology of chemical vapor infiltration and parameter area, applied in the field of high-throughput chemical vapor infiltration process, application and device, can solve the problems affecting the densification process, time-consuming, different SiC deposition rate and microstructure, etc., to reduce the research cost, shorten the exploration cycle, and quickly optimize the effect of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a high-throughput chemical vapor infiltration process based on parameter zone control includes the following steps:

[0024] 1. Regionalization of deposition parameters

[0025] A cold-walled CVI deposition furnace was used, and the deposition area was divided into different deposition intervals by carbon paper, so that the specific surface area (S V ) and residence time (τ) are different, changing the deposition temperature, deposition pressure, total flow rate, and precursor gas component ratio respectively can prepare high-throughput composite materials with different parameter systems and facilitate further rapid optimization of deposition parameters.

[0026] 2. Sample characterization and parameter optimization selection

[0027] High-throughput composite materials under different parameters were prepared by dividing the deposition area, and the samples in different deposition areas were measured and sliced to characterize the deposition inc...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

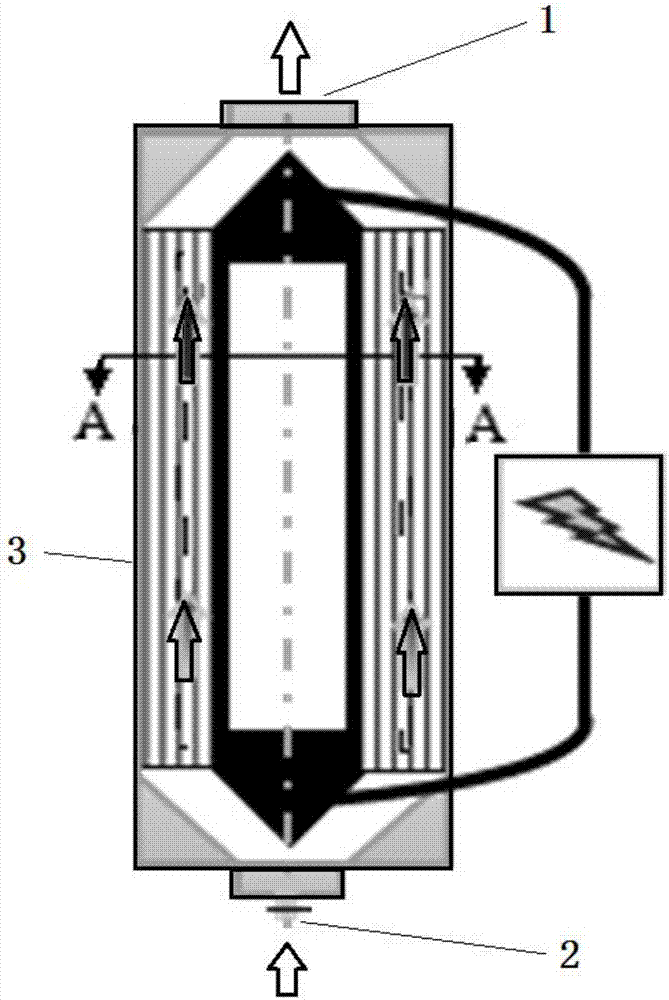

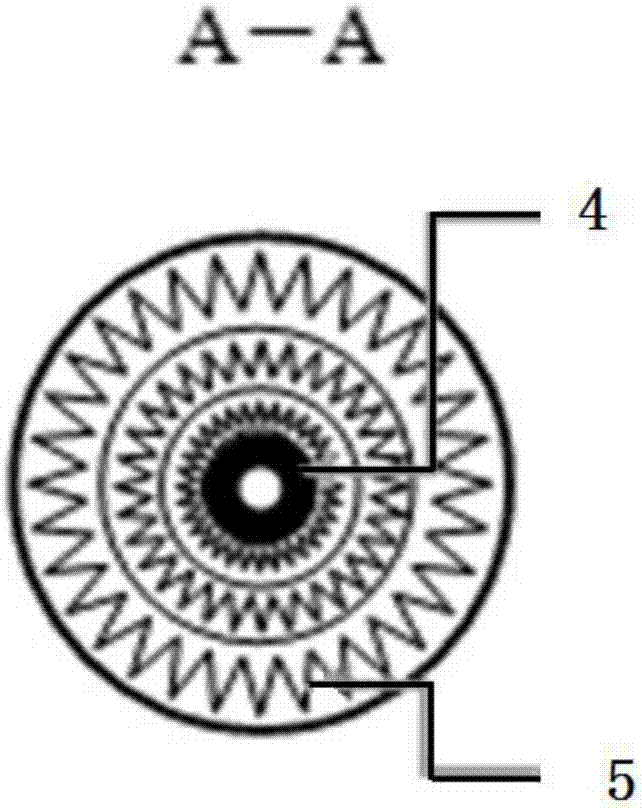

[0038] see figure 1 with figure 2 , this embodiment is based on the high-throughput chemical vapor infiltration process controlled by the parameter area, and the specific steps are as follows:

[0039] a. Place folded carbon paper in the deposition area of CVI deposition furnace 3, use carbon paper 5, and divide the deposition area into a set specific surface area Sv∈[103,105]m by changing the folding degree of carbon paper 5 -1 Then place a series of silicon carbide fiber prefabricated bodies with the same physical performance parameters as the deposition matrix in each deposition interval for 6 minutes, and then install the furnace. After the furnace is installed, vacuumize and check the air tightness of the system;

[0040] b. After confirming that the airtightness of the system meets the requirements, feed high-purity nitrogen gas until the system pressure is 80KPa, raise the temperatu...

Embodiment 3

[0044] This embodiment is basically the same as the previous embodiment, and the special features are:

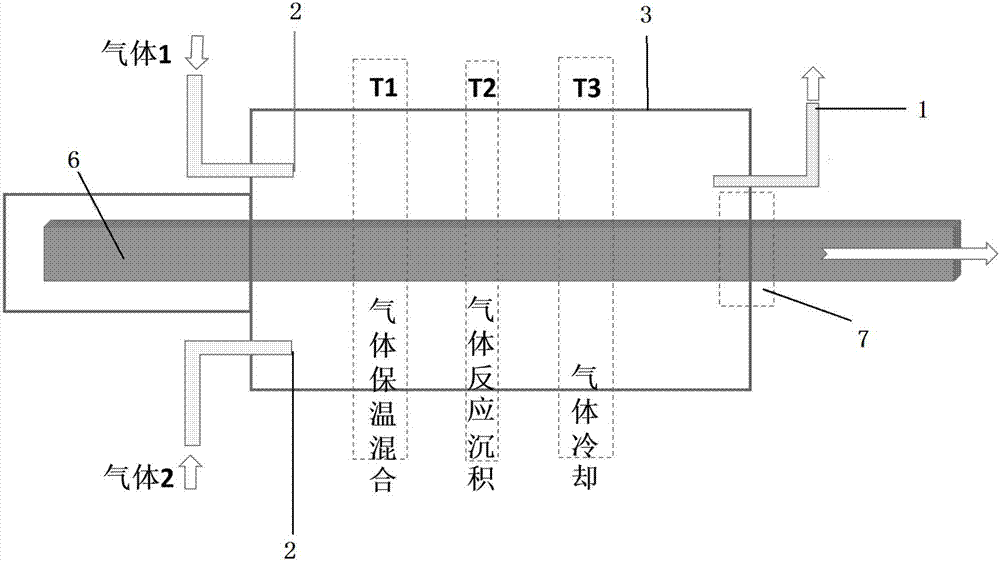

[0045] In this example, large-size SiC / BN / SiC composite components are prepared based on the optimal deposition parameters of BN and SiC combined with the regional movement of the preform, see image 3 , the inner cavity of the CVI deposition furnace 3 used in this embodiment is sequentially arranged and connected in a straight line by the premixing zone T1, the reaction chamber T2 and the gas cooling zone T3. Moving the sealing area 7, the elongated large-size deposition substrate 6 can enter the premixing area T1 from the furnace wall of the CVI deposition furnace 3, then pass through the reaction chamber T2 and the gas cooling area T3 in sequence, and pass through the moving sealing area 7, thereby The deposition substrate 6 is continuously produced into large-scale composite components. This embodiment is used for the rapid and uniform densification of large-scale comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com