C/SiC-SiO2 composite material and preparation method thereof

A composite material and billet technology, which is applied in the field of thermal structural composite materials and preparation, can solve the problems that restrict the wide application of C/SiC composite materials, the low utilization rate of raw materials, and the high cost of C/SiC composite materials, and achieve good mechanical properties. Performance and ablation resistance, cost reduction, environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

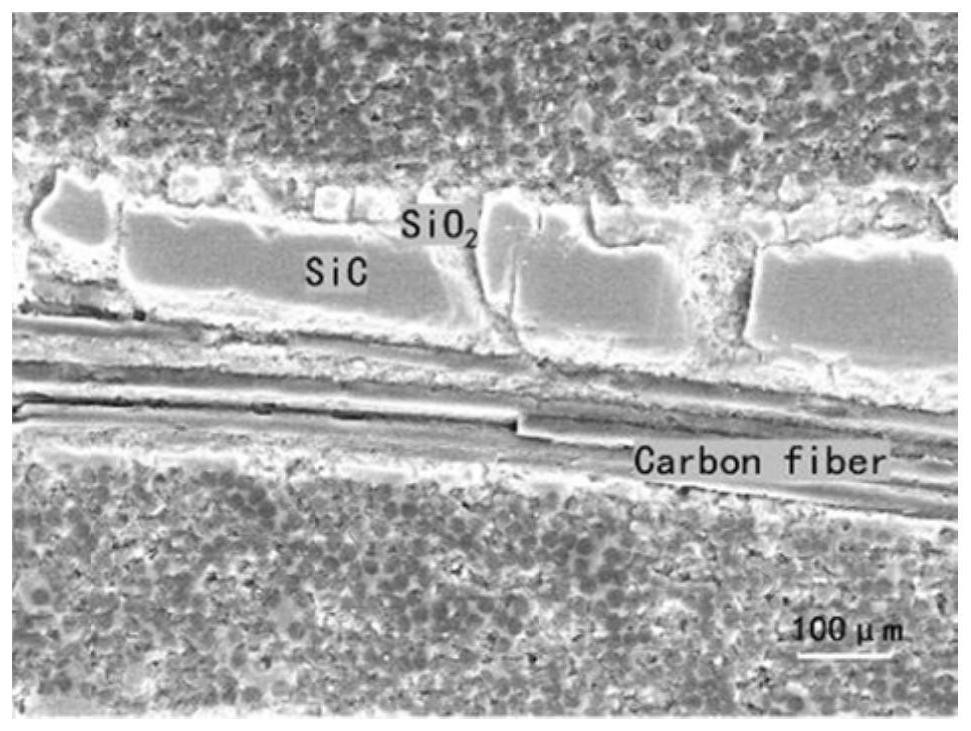

[0041] A C / SiC-SiO of the present invention 2 The preparation method of composite material, its step is:

[0042] (1) Put the carbon fiber fabric into the heat treatment equipment, under the protection of inert gas, raise the temperature to 400°C-1400°C, remove the organic matter such as sizing agent inside the fabric, and clean the fiber surface.

[0043] (2) Put the carbon fiber fabric after removing the organic matter into a chemical vapor deposition furnace, deposit a pyrolytic carbon interface layer on the surface of the carbon fiber, and the thickness of the interface layer should reach 50nm-2μm.

[0044] (3) The carbon fiber fabric after the deposition of the interface layer is subjected to high-temperature treatment at a temperature of 1400°C to 2500°C. The purpose of this step is to graphitize the interface layer between the carbon fiber and pyrolytic carbon, and reduce the interfacial layer between the carbon fiber and pyrolytic carbon and the substrate. bond streng...

Embodiment 1

[0056] C / SiC-SiO is used for hollow special-shaped structure products with an outer dimension envelope of 1500m×400mm×50mm and a wall thickness of 3-10mm 2 Composite materials were developed. The specific development steps are as follows:

[0057] (1) According to the product drawing, use T300-3K carbon fiber and lay-up-sewing process to weave the fabric, take samples in the blank margin area, and determine whether the fabric density meets 0.7g / cm 3 The above; put the carbon fiber fabric that meets the requirements into the heat treatment equipment, and under the protection of argon, heat up to 600°C to remove the organic matter such as sizing agent inside the fabric to clean the fiber surface.

[0058] (2) Put the fabric after removing the organic matter into a chemical vapor deposition furnace, deposit a pyrolytic carbon interface layer on the surface of the carbon fiber, and the thickness of the interface layer is about 150nm.

[0059] (3) The deposited fabric is subjecte...

Embodiment 2

[0067] C / SiC-SiO is used for hollow special-shaped structure products with an outer dimension envelope of 1800m×500mm×50mm and a wall thickness of 5mm 2 Composite materials were developed. The specific development steps are as follows:

[0068] (1) According to the product drawing, use T300-1K fiber and lay-up-sewing process to weave the fabric, take samples in the blank margin area, and determine whether the fabric density meets 0.7g / cm 3 The above; put the carbon fiber fabric that meets the requirements into the heat treatment equipment, and under the protection of argon, heat up to 600°C to remove the organic matter such as sizing agent inside the fabric to clean the fiber surface.

[0069] (2) Put the fabric after removing the organic matter into a chemical vapor deposition furnace, deposit a pyrolytic carbon interface layer on the surface of the carbon fiber, and the thickness of the interface layer is about 500nm.

[0070] (3) The deposited fabric is subjected to high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com