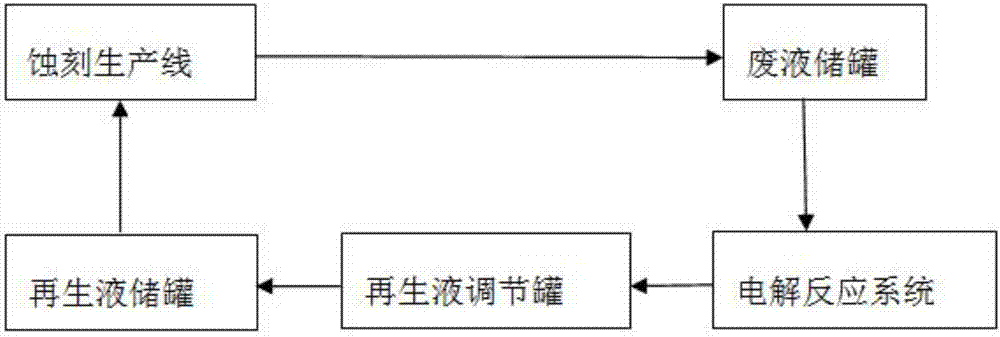

Electrolytic reaction system and cupric chloride etchant regeneration and copper extraction technology

A technology of electrolytic reaction and electrolytic cell, applied in the field of electrolysis, can solve problems such as inability to achieve online circulation and increase equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

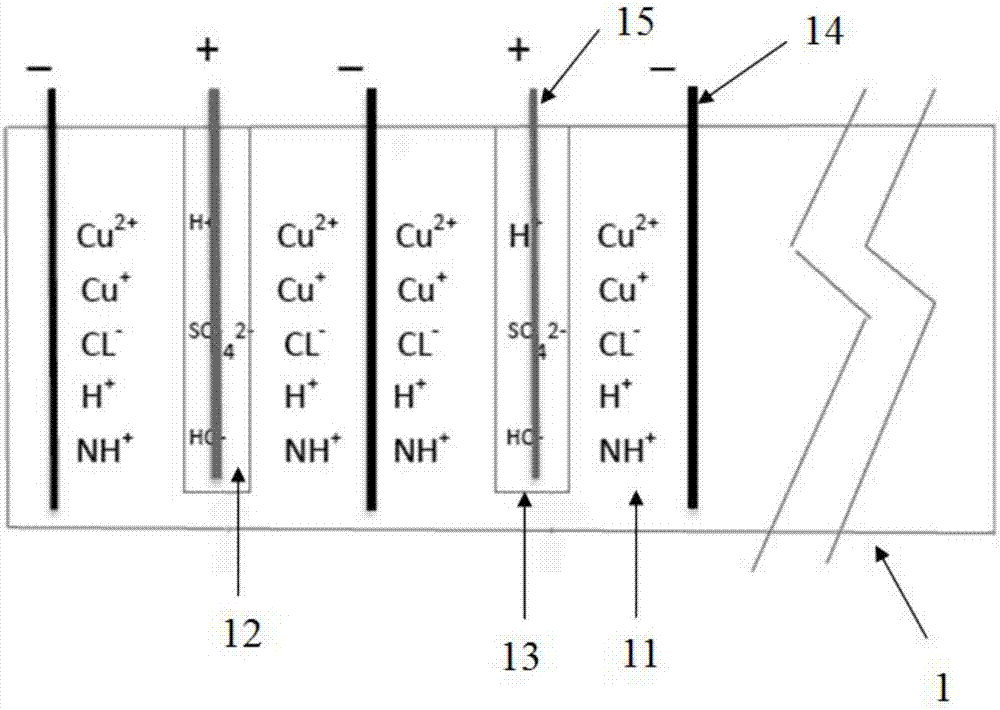

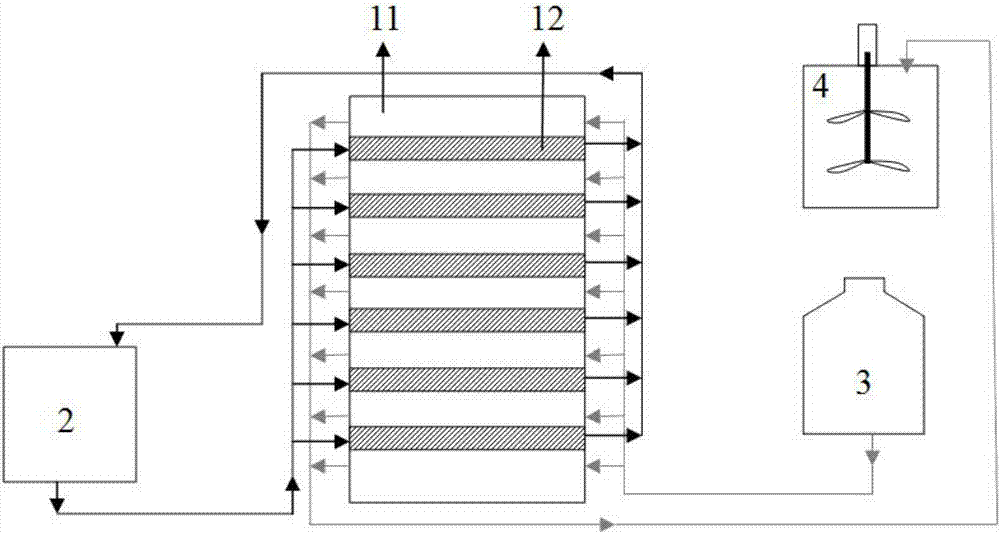

[0042] Place the waste etching solution to be regenerated in the cathode chamber 11; place dilute sulfuric acid in the anode chamber 12, and set the concentration of dilute sulfuric acid at 20-25%, with the oxygen evolution type DSA iridium titanium plate as the anode plate 15, and the titanium electrode plate As the cathode plate 14, each anode chamber 12 is surrounded by a 0.6mm thick CR61CMP-447 cationic membrane, connected to the power supply, at 4A / dm 2 Electrolysis was performed at a current density. During the electrolysis process, the catholyte and the anolyte are continuously circulated respectively.

[0043] The chemical reaction process of the above electrolysis process is the anode: OH --e→O 2 ; Cathode: Cu 2+ +e → Cu.

[0044] There are some monovalent copper ions in the etching waste liquid, and the oxygen precipitated in the anode is introduced into the cathode solution through the catheter to oxidize the monovalent copper ions to divalent copper ions: Cu +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com