High-precision assembling method for pile shoe of offshore platform

A technology of offshore platform and assembly method, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of inconvenient production, short service life, poor structure, etc., so as to facilitate production and installation, and have better structural strength , Ease of assembly and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

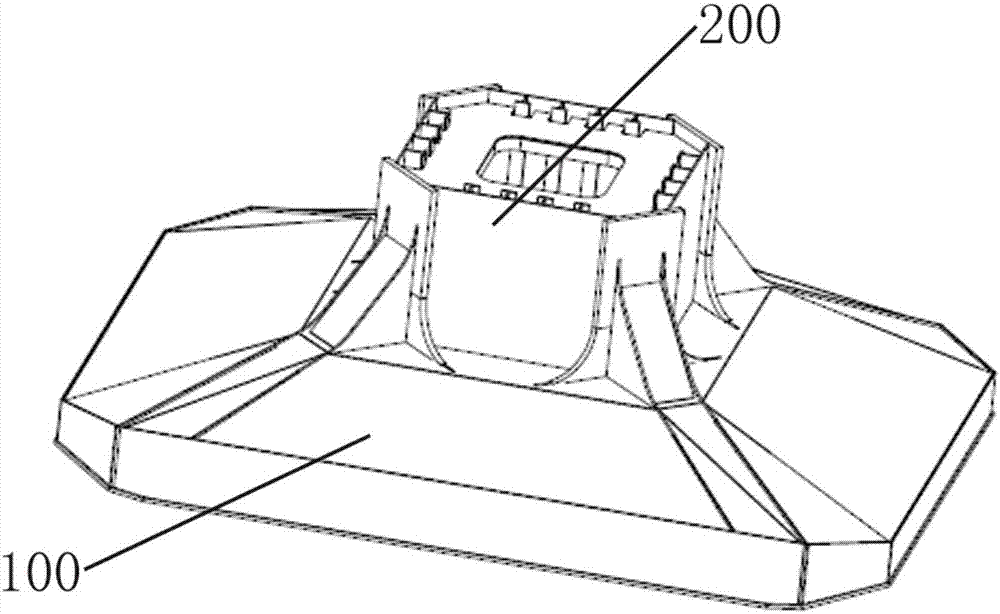

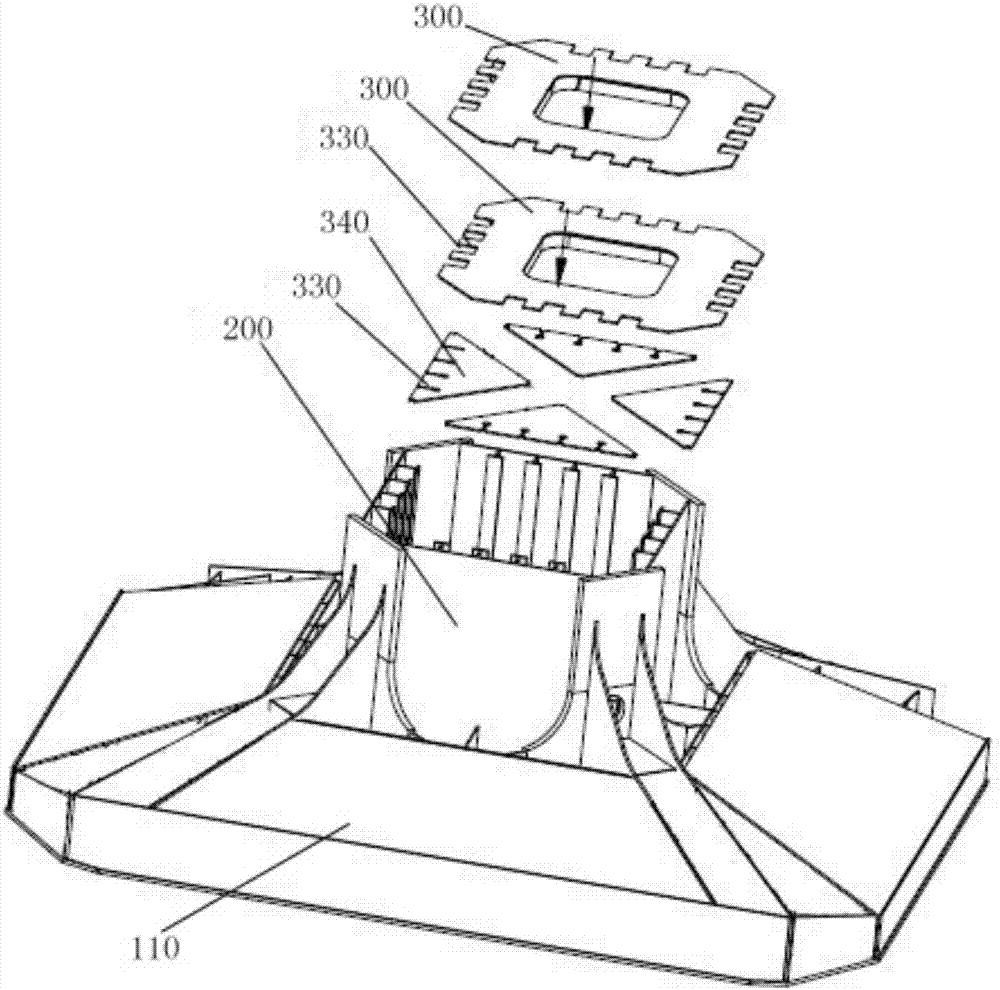

[0036] like Figure 1-6 As shown, a high-precision assembly method for offshore platform spud cans, the main body is an octagonal spud can 100 and an octagonal spud leg 200 protruding from the spud can 100, including the following steps:

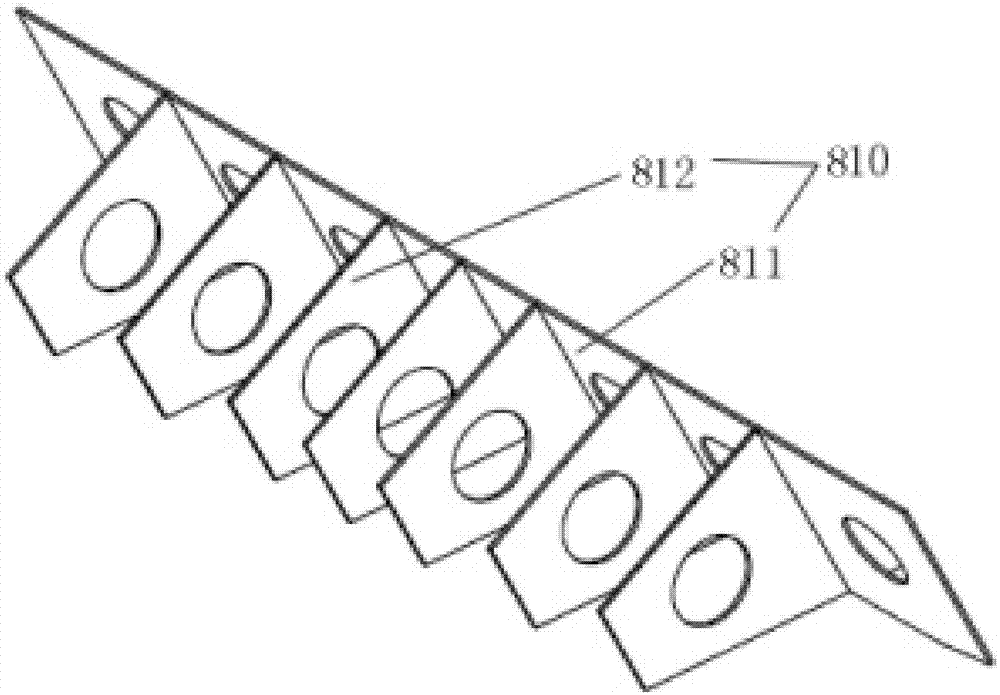

[0037] Step A, producing parts, manufacturing spud shoe 100 and spud leg 200 parts, said spud shoe 100 includes casing 110 , bottom plate 120 and middle assembly 800 , and said spud leg 200 includes guide plate 400 and shroud 500 and a diagonal bulkhead assembly 600;

[0038]Step B, setting reference components, making a concave tire frame, and constraining the bottom plate 120 to the tire frame;

[0039] Step C, setting up the main structure, fixing the trunk of the leg portion 200 formed by the guide plate 400 and the hoarding plate 500 to the bottom plate 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com