Solar heat collecting tube and preparation method and purpose thereof

A technology of solar heat collecting tubes and heat collecting tubes, which is applied in the field of solar light energy and heat utilization, can solve the problems of inconvenient sealing and processing, heat loss of unsafe heat collecting tubes, etc., and achieve excellent corrosion resistance, stable product quality, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

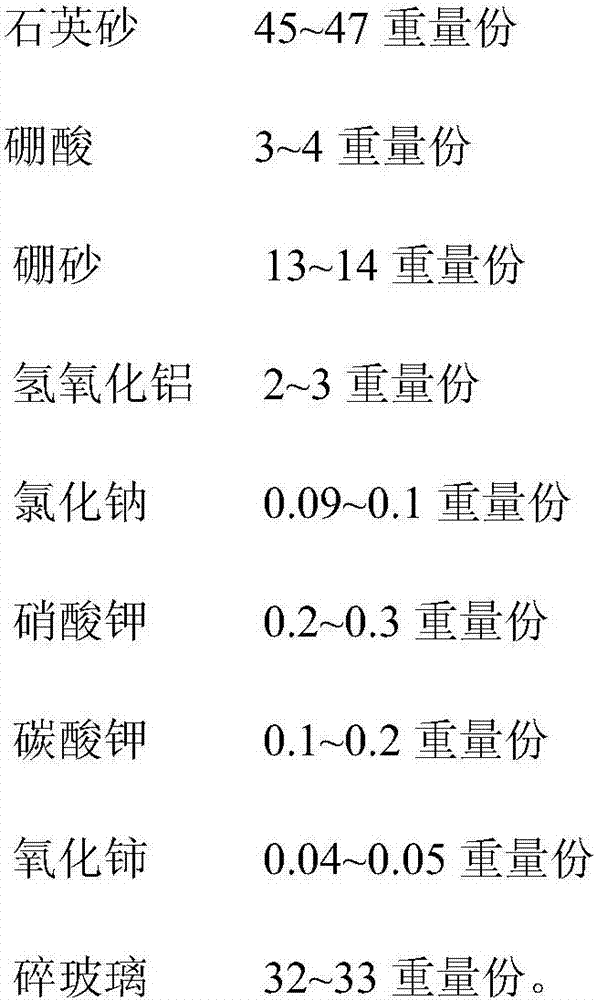

[0051] The glass outer tube described in this embodiment contains the following raw material components and parts by weight:

[0052]

[0053] The cullet contains the following raw material components and parts by weight:

[0054]

[0055]

[0056] The metal inner tube is made of stainless steel. The metal inner tube is 304 stainless steel tube.

[0057] The model of the Kovar alloy is that the alloy of the Kovar alloy ring is Fe-Ni-Co hard glass. According to the GB / T4339-2008 standard, the average coefficient of linear expansion of the Kovar alloy at 20-400°C is 4.047×10 -6 / °C.

[0058] Based on the total mass of the Fe-Ni-Co hard glass, the chemical composition of the Fe-Ni-Co hard glass is as follows:

[0059] Ni 31.3~31.8%

[0060] Co 18.1~18.6%

[0061] The balance is iron.

[0062] Based on the total mass of the Fe-Ni-Co hard glass, the content of Al in the Fe-Ni-Co hard glass is not more than 0.10%, the content of Mg is not more than 0.10%, and the con...

Embodiment 2

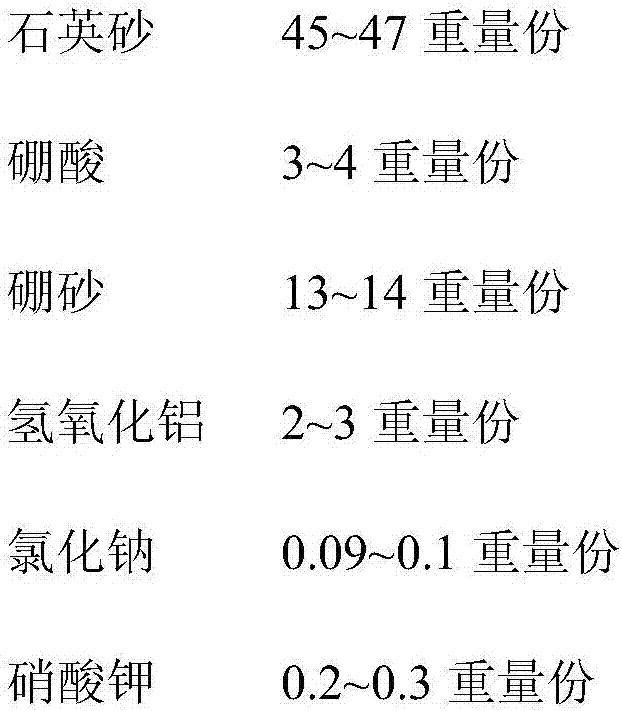

[0071] The glass outer tube described in this embodiment contains the following raw material components and parts by weight:

[0072]

[0073]

[0074] The cullet contains the following raw material components and parts by weight:

[0075]

[0076] The metal inner tube is made of stainless steel. The metal inner tube is 304 stainless steel tube.

[0077] The model of the Kovar alloy is that the alloy of the Kovar alloy ring is Fe-Ni-Co hard glass. According to the GB / T4339-2008 standard, the average coefficient of linear expansion of the Kovar alloy at 20-400°C is 4.047×10 -6 / °C.

[0078] Based on the total mass of the Fe-Ni-Co hard glass, the chemical composition of the Fe-Ni-Co hard glass is as follows:

[0079] Ni 31.3~31.8%

[0080] Co 18.1~18.6%

[0081] The balance is iron.

[0082] Based on the total mass of the Fe-Ni-Co hard glass, the content of Al in the Fe-Ni-Co hard glass is not more than 0.10%, the content of Mg is not more than 0.10%, and the con...

Embodiment 3

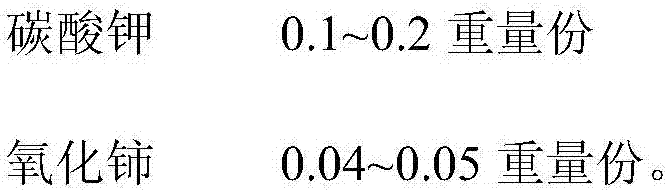

[0091] The glass outer tube described in this embodiment contains the following raw material components and parts by weight:

[0092]

[0093] The cullet contains the following raw material components and parts by weight:

[0094]

[0095]

[0096] The metal inner tube is made of stainless steel. The metal inner tube is 304 stainless steel tube.

[0097] The model of the Kovar alloy is that the alloy of the Kovar alloy ring is Fe-Ni-Co hard glass. According to the GB / T4339-2008 standard, the average coefficient of linear expansion of the Kovar alloy at 20-400°C is 4.047×10 -6 / °C.

[0098] Based on the total mass of the Fe-Ni-Co hard glass, the chemical composition of the Fe-Ni-Co hard glass is as follows:

[0099] Ni 31.3~31.8%

[0100] Co 18.1~18.6%

[0101] The balance is iron.

[0102] Based on the total mass of the Fe-Ni-Co hard glass, the content of Al in the Fe-Ni-Co hard glass is not more than 0.10%, the content of Mg is not more than 0.10%, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com