A self-breaking material bridging circulation dryer and its process system

A cycle drying and drying machine technology, which is applied in the direction of drying machines, dry cargo handling, and drying solid materials, etc., can solve the problems of long drying time, high cost, and high energy consumption, and achieve enhanced drying process, smooth flow, and larger The effect of ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

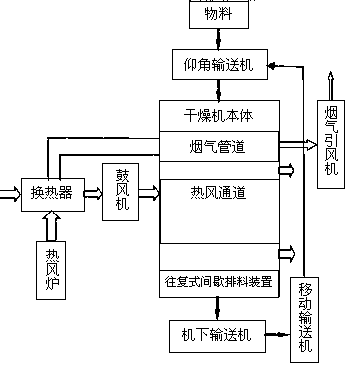

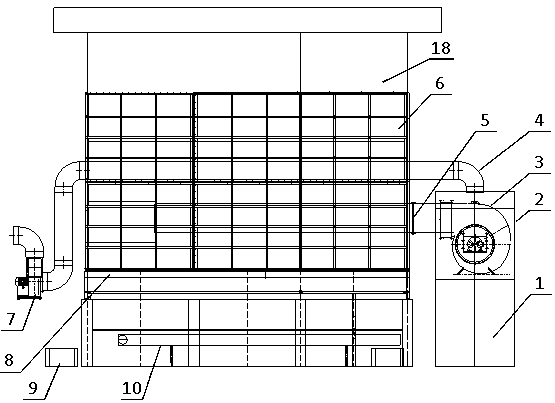

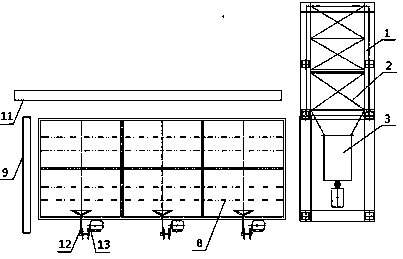

[0038] Process system flow of the present invention is as figure 1 As shown, the sequential connection relationship of equipment according to the hot air flow direction is hot blast stove 1, heat exchanger 2, blower 3, and hot air passage 5; Dryer body 6, diverter 15, reciprocating intermittent discharge device 8, under-machine conveyor 10, mobile conveyor 9, elevation conveyor 11; dryer body 6, the surrounding surface is made of ventilated mesh panels, from top to bottom The design of the device is a feed port 18, a flue gas pipe 4, a hot air channel 5, a flow divider 15, a reciprocating intermittent discharge device 8, and the reciprocating intermittent discharge device 8 includes a crank linkage mechanism 12 driven by a motor, an electromagnetic closer 13. Discharging pallet 14, reset device 17. The electromagnetic closer 13 is connected to the crank-link mechanism 12 and the discharge pallet 14 , and the discharge pallet 14 is connected to the frame through a reset device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com