Method for performing qualitative and quantitative analysis on chalcopyrite leaching residue by using simultaneous thermal analyzer

A technology of simultaneous thermal analysis and thermal analysis method, which is applied in the field of qualitative and quantitative analysis of chalcopyrite leaching slag, and can solve problems such as large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

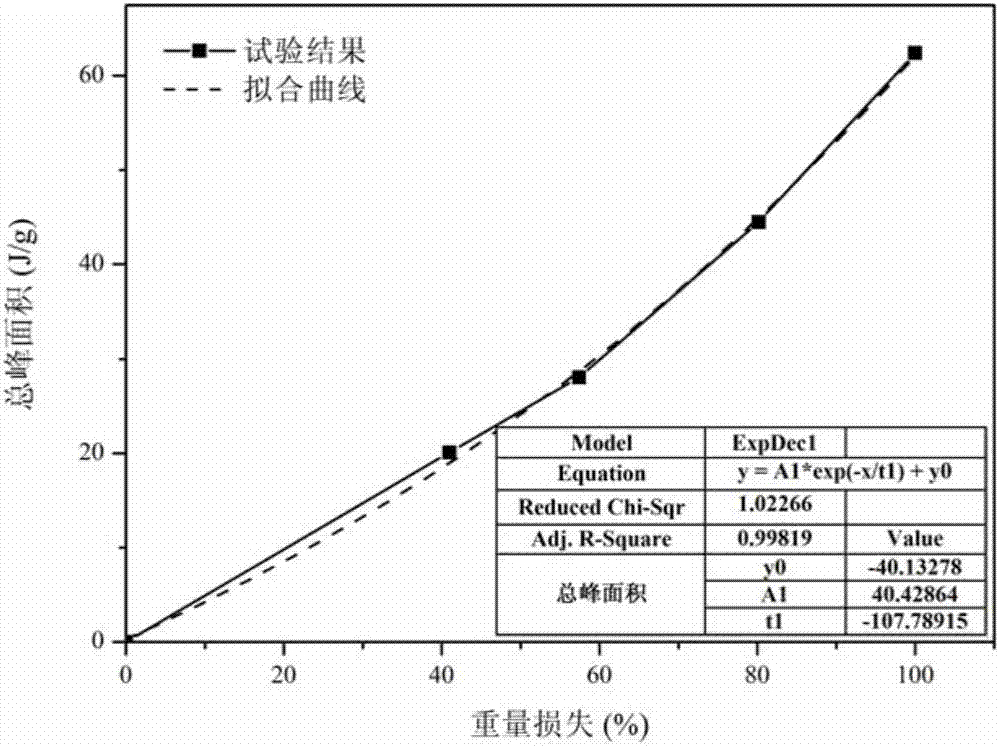

[0044] 1. Determination and results of artificial mixed ore are attached figure 1 shown.

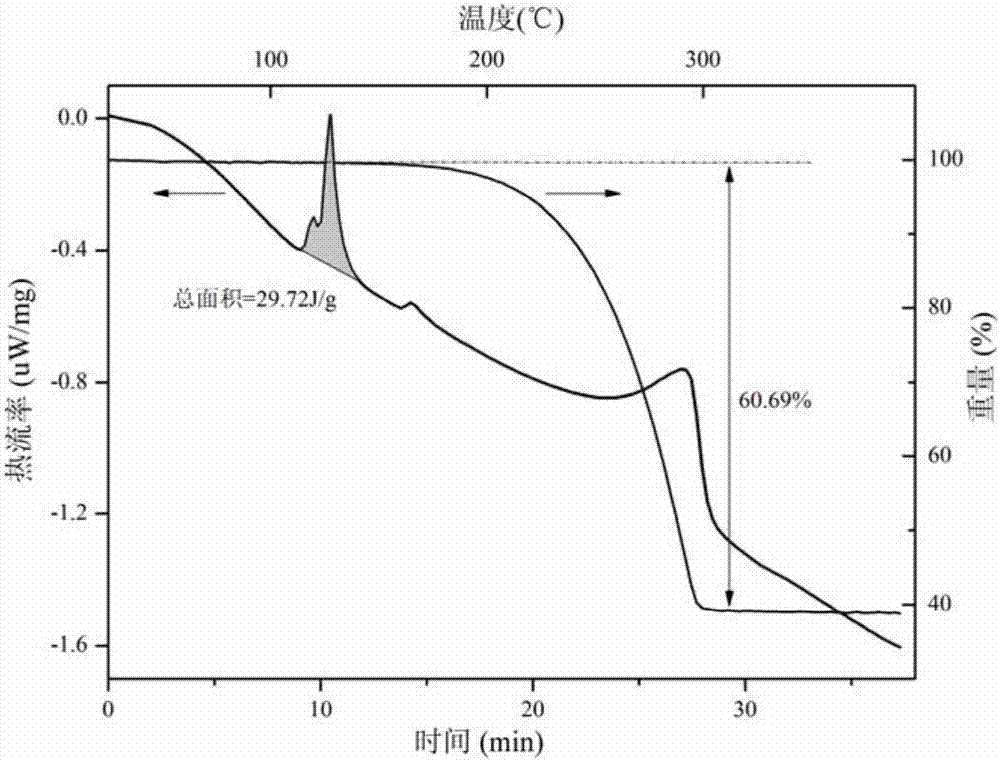

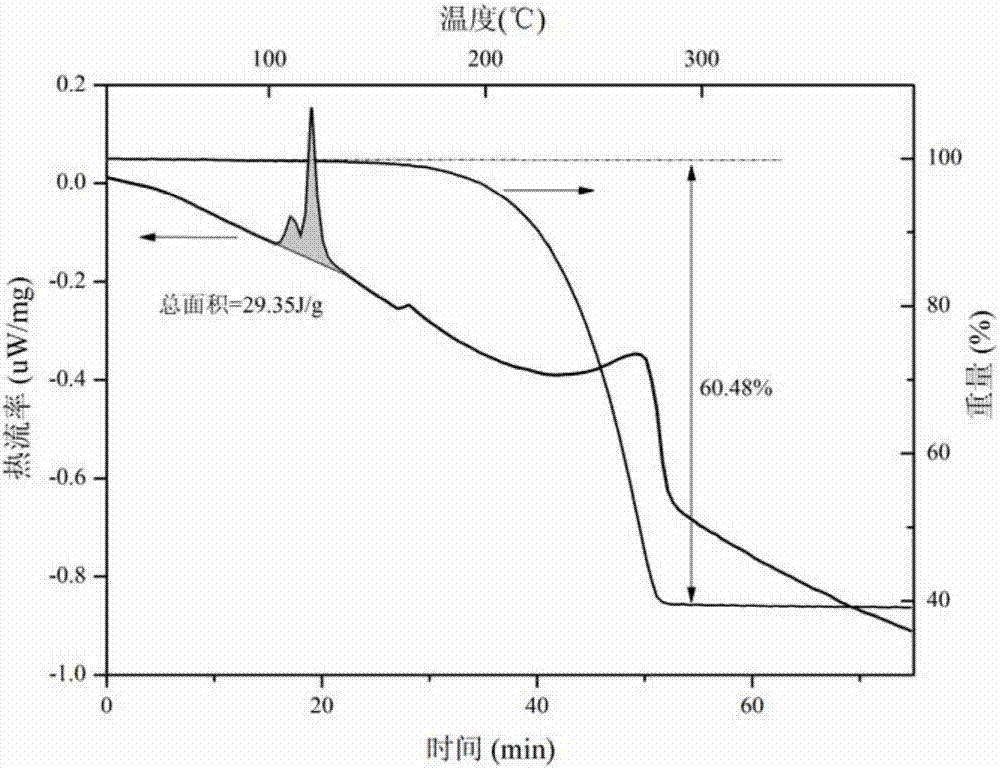

[0045] 2. Carry out synchronous thermal analyzer test on chalcopyrite leaching slag. The temperature was raised from 25°C to 400°C at a rate of 5°C / min. Nitrogen is used as protective gas, and the flow rate of nitrogen is 100ml / min. Get the heat and mass change curve, as attached image 3 shown.

[0046] 3. by attached image 3 It can be seen that the DSC curve has two endothermic peaks at 112.4°C and 120.2°C, corresponding to orthorhombic sulfur and monoclinic sulfur, respectively. The total fusion enthalpy of these two sulfurs is 29.35 J / g. Put this value into figure 1In the fitting curve equation, the content of sulfur is obtained as 58.67%. That is, the total content of elemental sulfur in the leaching residue. The maximum weight loss was 60.48%, with a difference of 1.81%.

[0047] 4. Heat the toluene to 60°C, pour 3.00230g of the leaching residue into the toluene, stir wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com