Steel strip sheathed variable frequency heating cable for oil well

A technology for heating cables and steel strips, applied in ohmic resistance heating, heating element materials, heating element shapes, etc., can solve problems such as low heating efficiency, inconvenient construction, and manufacturing difficulties, and achieve high heating efficiency, convenient construction and installation, and maintenance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

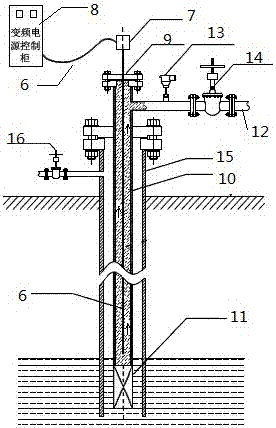

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

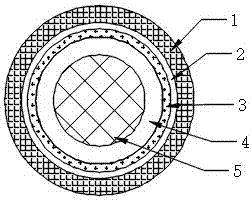

[0035] Such as figure 1 As shown, the steel tape sheathed frequency conversion heating cable for oil wells provided by the present invention consists of a radiation cross-linked polyolefin sheath layer 1, a galvanized steel tape layer 2, a glass fiber tape layer 3, and a radiation cross-linked polyolefin insulation layer 4 and the conductor 5 are wrapped sequentially from the outside to the inside; the galvanized steel strip layer 2 is a double-layer armored structure, and each layer is wrapped with gaps; the glass fiber tape layer 3 is a double-layer wrapped structure, The covering rate of each layer of glass fiber tape is 50%; the conductor 5 is composed of 7 rare-earth high-iron aluminum alloy wires twisted and pressed tightly; the lower end of the conductor 5 in the oil pipe is connected with the galvanized steel strip layer 2 to form a loop.

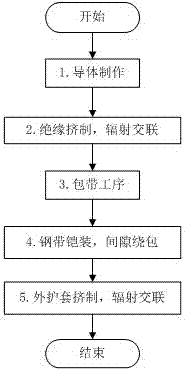

[0036] In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com