System for and method of processing transparent materials by using laser beam focal lines adjustable in length and diameter

A transparent material, laser beam technology, used in laser welding equipment, metal processing equipment, optics, etc., can solve problems such as time-consuming and limiting output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

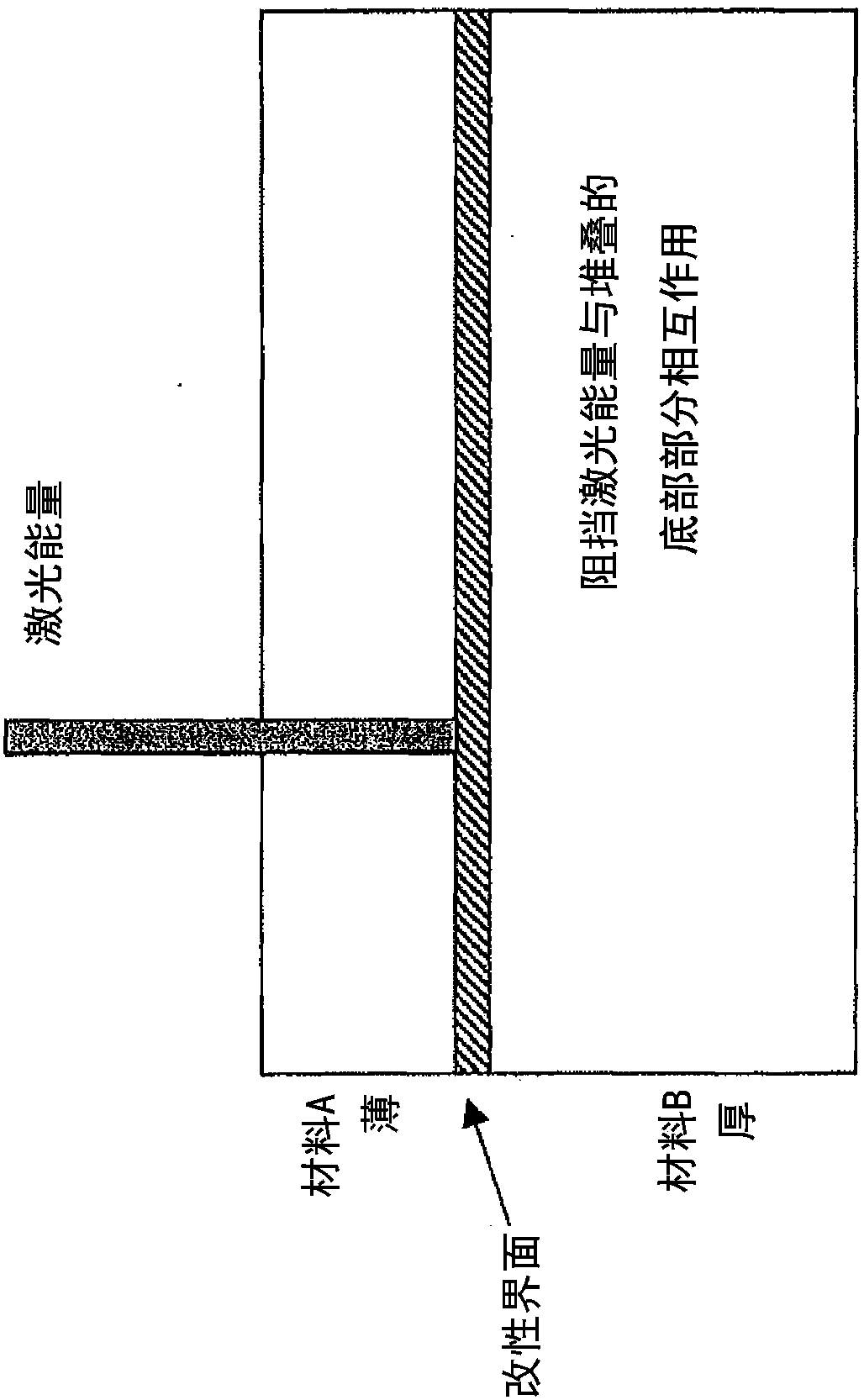

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

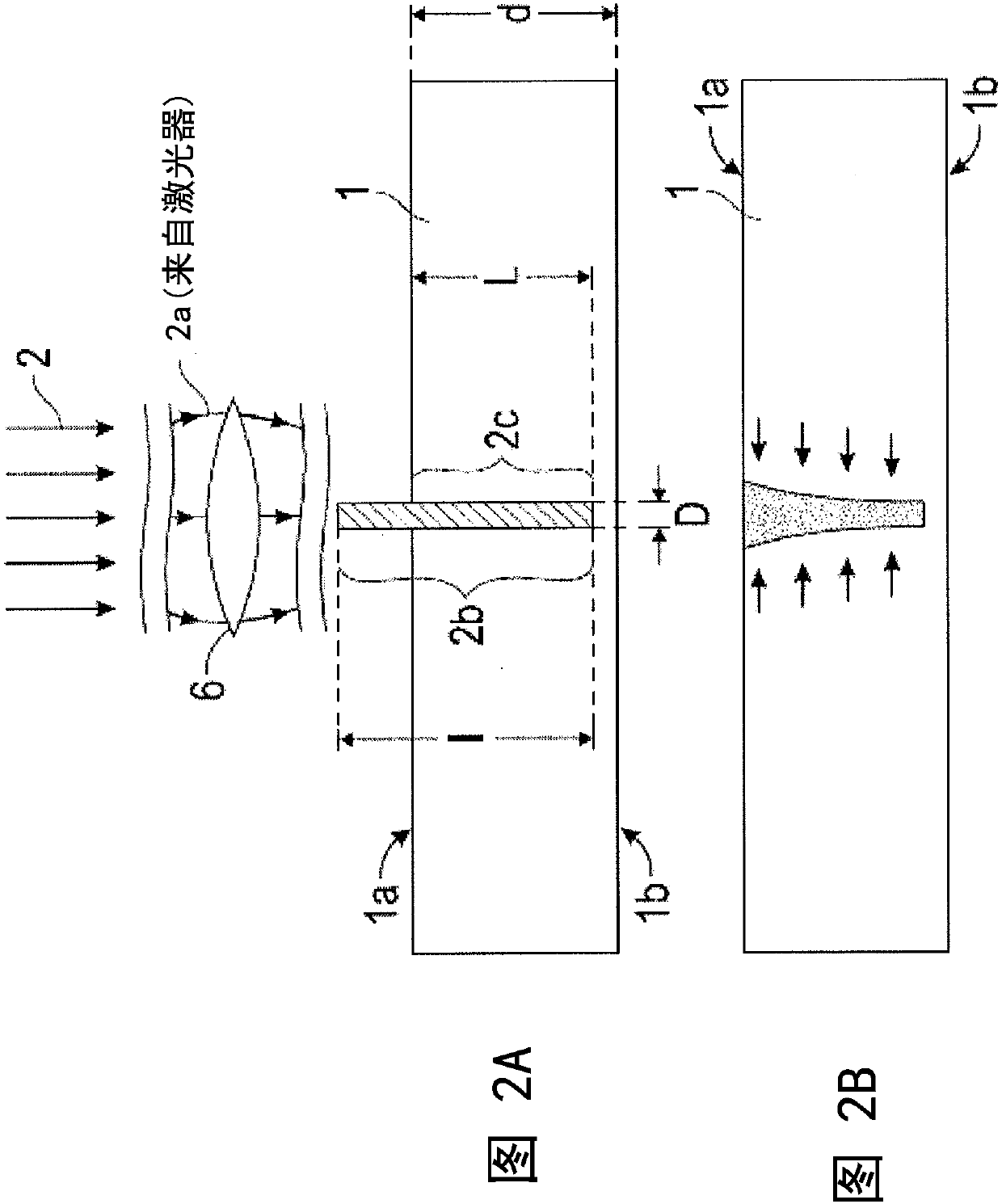

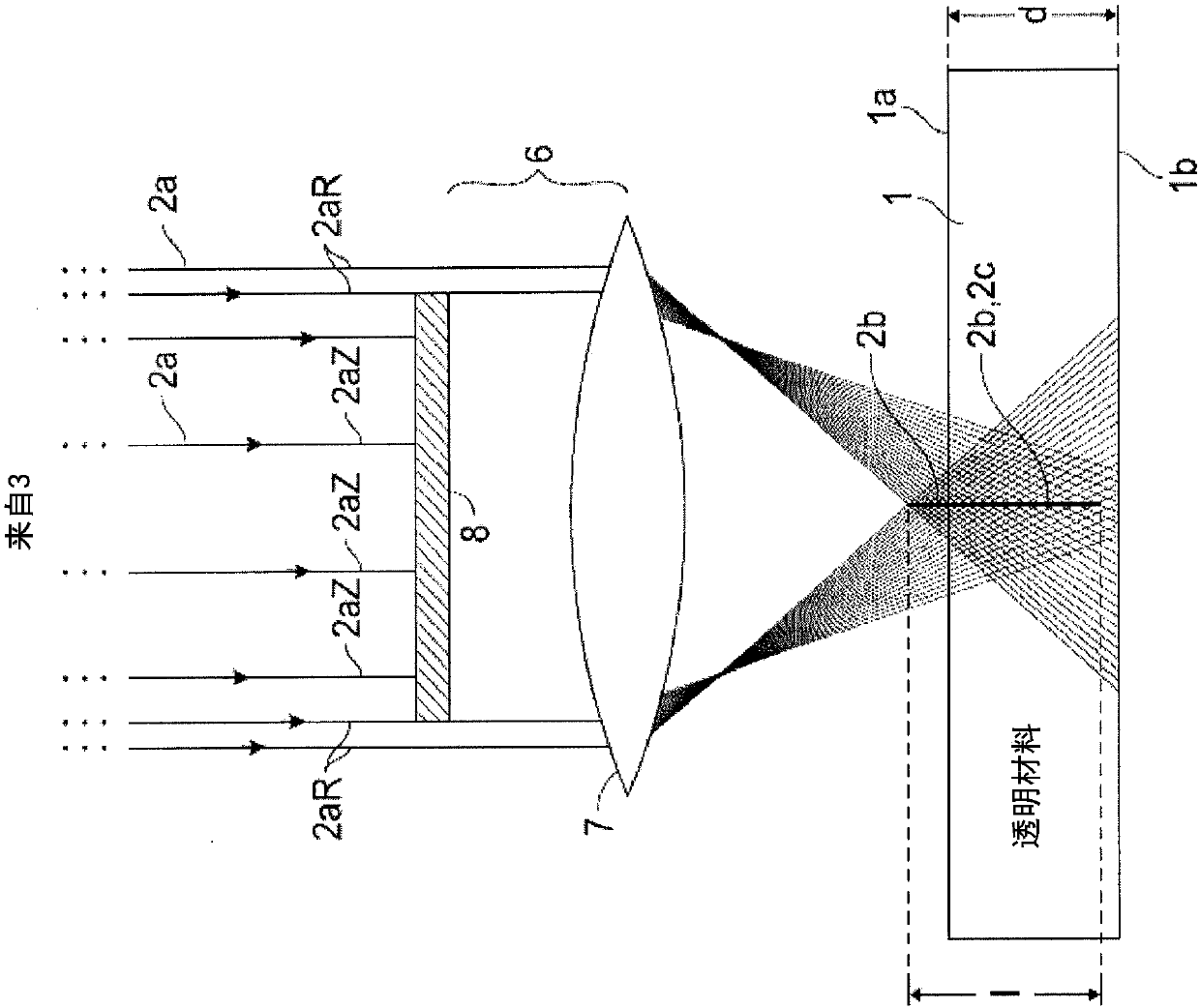

[0029] Embodiments described herein relate to methods and systems for optically producing high-precision cuts in or through transparent materials. Subsurface damage from the cutting process can be limited to a depth of 60 microns or less, and cutting can generate only a small amount of debris. Cutting transparent materials with a laser according to the present disclosure may also be referred to herein as drilling or laser drilling or laser machining. A material is substantially transparent to the laser wavelength when the absorption at this wavelength is less than about 10%, preferably less than about 1%, per millimeter of material depth.

[0030] Typically, a laser beam is transformed into a laser beam focal line positioned within a block of material, such as glass, to create a defect line within the material. The material can then be separated along these defect lines. The laser beam focal line can also be used to make holes in materials, such as holes in interposers of se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com