Belt Conveyor Operation Monitoring System and Method

A belt conveyor and position machine technology, which is applied in the directions of transportation and packaging, conveyor objects, conveyor control devices, etc., can solve the problems of equipment downtime, large load, long running time, etc., to achieve reduced size, low power consumption, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

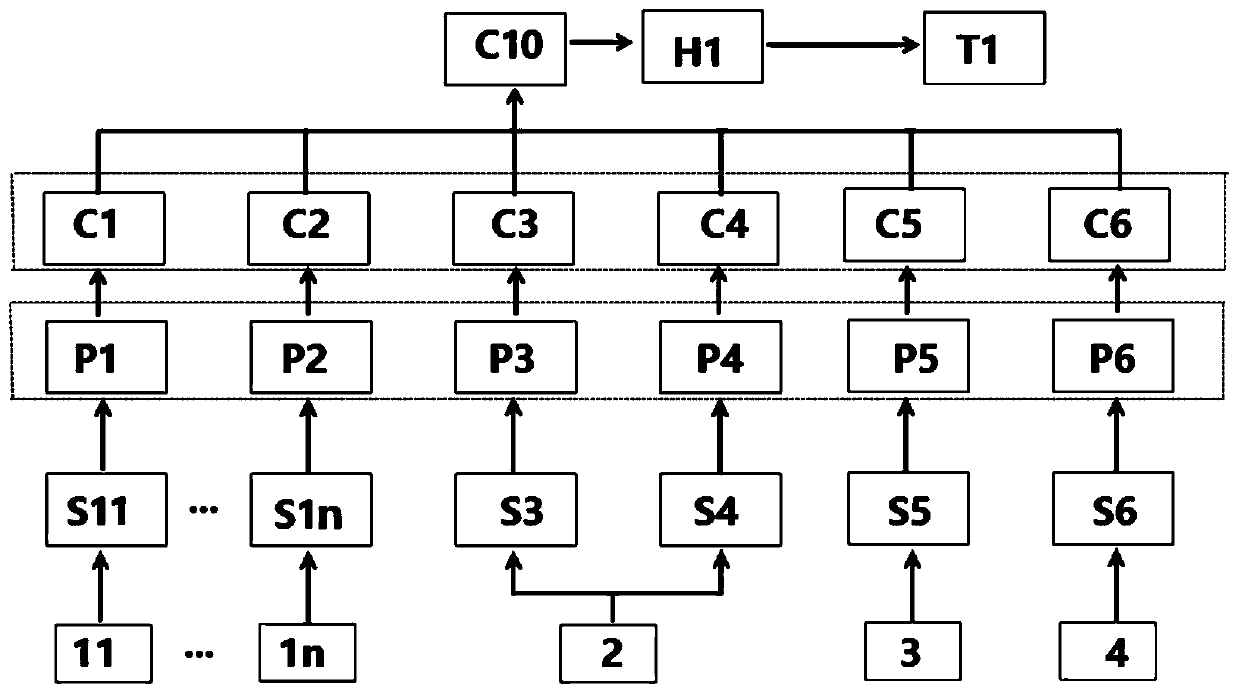

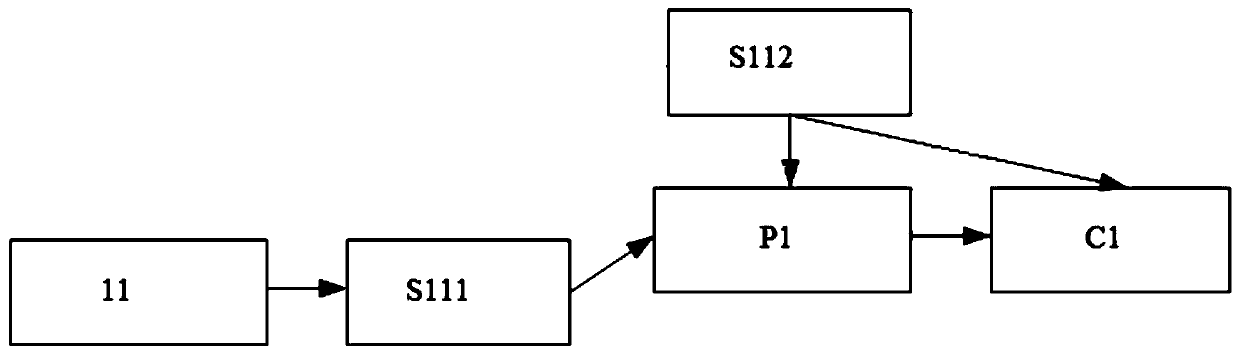

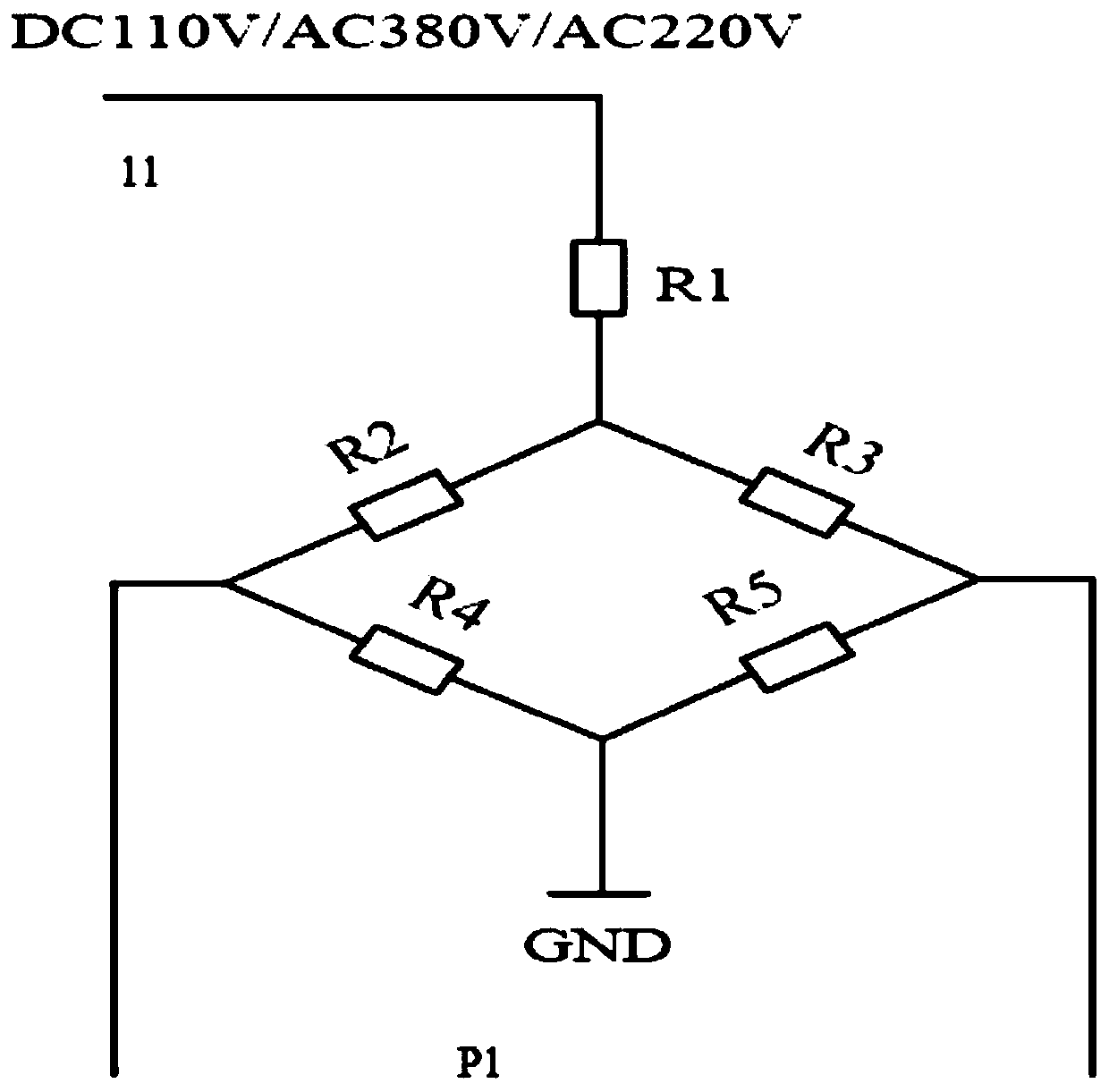

[0023] Such as figure 1 As shown, a belt conveyor operation monitoring system includes: a data processing module, a voltage conversion and detection module, a vibration sensor S3, a temperature sensor S4 and S6, a displacement sensor S5, a wireless communication module and an upper computer H1, and the wireless communication module is used In order to realize the communication between the data processing module and the upper computer H1, the wireless communication module includes wireless communication sub-modules C1, C2, C3, C4, C5 and C6 connected to the data processing module respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com