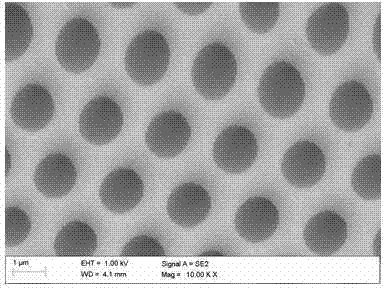

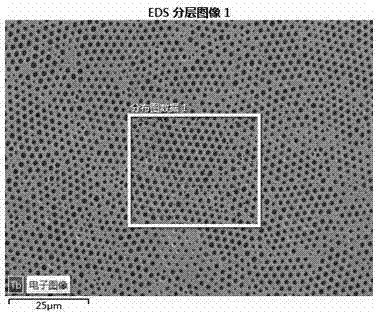

Polystyrene-b-Tb complex amphipathic segmented copolymer and honeycomb-structured porous film as well as preparation method

A technology of amphiphilic blocks and complexes, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of single product types, less monomers, and harsh anionic polymerization conditions, and achieve good solubility and order good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A PS-b-Tb complex amphiphilic block copolymer is prepared from the following raw materials in parts by weight (0.05 g per part): 100 parts of A component, 100 parts of B component Parts, 1 part of azobisisobutyronitrile, 200 parts of cyclohexanone;

[0027] Among them, the weight fraction and proportion of component A are as follows (0.05 g per part): 100 parts of styrene, S-1-dodecyl-S'-(α,α'-dimethyl-α"- Acetic acid) trithiocarbonate (DDMAT) 0.7 parts, azobisisobutyronitrile 0.15 parts, cyclohexanone 100 parts; the weight fraction and proportion of component B are as follows (0.05 g per part): terbium nitrate (Tb (NO 3 ) 3 ) 100 parts, α-methacrylic acid 100 parts, salicylic acid 175 parts, ethanol 430 parts;

[0028] The preparation method of the PS-b-Tb complex amphiphilic block polymer is as follows: mix the styrene, DDMAT, azobisisobutyronitrile and cyclohexanone of the above-mentioned component A in proportion and stir evenly, o C reacted under nitr...

Embodiment 2

[0032] Example 2 A PS-b-Tb complex amphiphilic block copolymer is prepared from the following raw materials in parts by weight (0.05 g per part): 100 parts of A component, 50 parts of B component Parts, 0.8 parts of azobisisobutyronitrile, 150 parts of cyclohexanone;

[0033] Among them: the weight fraction and proportion of component A are as follows (take 0.05 g per part): 100 parts of styrene, S-1-dodecyl-S'-(α,α'-dimethyl-α″- Acetic acid) trithiocarbonate (DDMAT) 0.5 parts, azobisisobutyronitrile 0.15 parts, cyclohexanone 80 parts; the weight fraction and proportion of component B are as follows (0.05 g per part): terbium nitrate (Tb (NO 3 ) 3) 100 parts, α-methacrylic acid 100 parts, salicylic acid 175 parts, ethanol 400 parts.

[0034] The PS-b-Tb complex amphiphilic block polymer and its preparation method are as follows: mix the styrene, DDMAT, azobisisobutyronitrile and cyclohexanone of the above-mentioned component A in proportion and stir evenly, 80 o C reacted ...

Embodiment 3

[0038] Example 3 A PS-b-Tb complex amphiphilic block copolymer is prepared from the following raw materials in parts by weight (0.05 g per part): 100 parts of A component, 60 parts of B component Parts, 1.2 parts of azobisisobutyronitrile, 250 parts of cyclohexanone;

[0039] Among them, the weight fraction and proportion of component A are as follows (0.05 g per part): 100 parts of styrene, S-1-dodecyl-S'-(α,α'-dimethyl-α"- Acetic acid) 1 part of trithiocarbonate (DDMAT), 0.2 part of azobisisobutyronitrile, 150 parts of cyclohexanone; the weight fraction and proportion of component B are as follows (0.05 g per part): terbium nitrate (Tb (NO 3 ) 3 ) 100 parts, α-methacrylic acid 100 parts, salicylic acid 175 parts, ethanol 500 parts.

[0040] The preparation method of the PS-b-Tb complex amphiphilic block polymer is as follows: mix the styrene, DDMAT, azobisisobutyronitrile and cyclohexanone of the above-mentioned component A in proportion and stir evenly, o C reacted unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com