Surface-protective film and optical component attached with the same

A technology of surface protection film and peeling film, which is applied in the direction of optical components, optics, film/sheet adhesive, etc. It can solve the problems of difficult to paste FPR film, etc., and achieve productivity, less pollution, and anti-aging degradation over time. Effect of stripping static electricity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

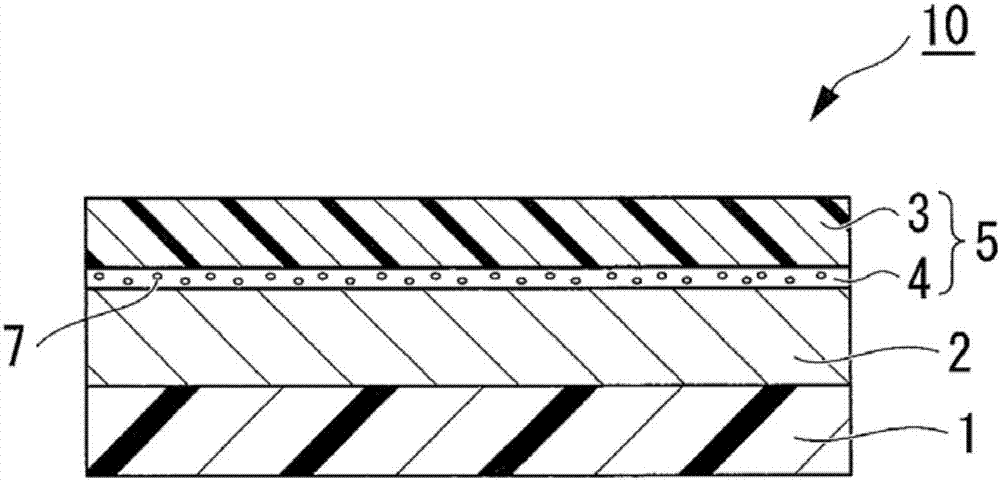

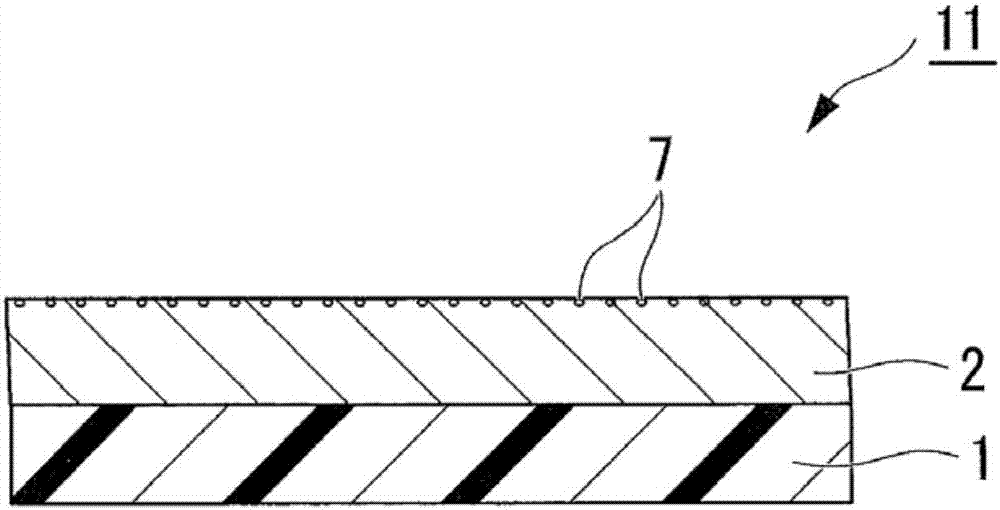

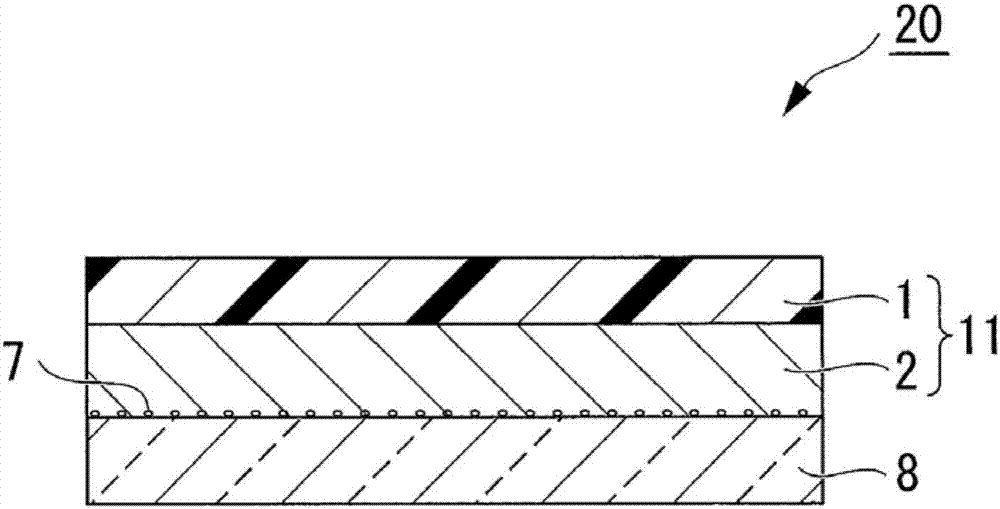

[0080] (Preparation of surface protection film)

[0081] 5 parts by weight of addition reaction silicone (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-345), 0.75 parts by weight of N-butyl-4 as an ionic compound with a melting point of 48° C. -picoline hexafluorophosphate, 0.75 parts by weight of tetraethylene glycol di-2-ethylhexanoate, 95 parts by weight of toluene and ethyl acetate as a 1:1 mixed solvent, 0.05 parts by weight of platinum catalyst (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-212) were mixed, stirred and mixed, and the coating material for forming the release agent layer of Example 1 was prepared. On the surface of a polyethylene terephthalate film with a thickness of 38 μm, the paint used to form the release agent layer of Example 1 was coated with a Meyer bar so that the thickness after drying was 0.2 μm, and a 120° C. Dry in a hot air circulation oven for 1 minute to obtain the peeling film of Example 1. On the other hand...

Embodiment 2

[0084] In the same manner as in Example 1, except that instead of N-butyl-4-methylpyridine hexafluorophosphate, 1-methyl-3-ethylimidazolium hexafluorophosphate, which is an ionic compound having a melting point of 62°C, was used Thus, the surface protective film of Example 2 was obtained.

Embodiment 3

[0093]Except for using the following adhesive composition instead of the adhesive composition of Example 1, the surface protection film of Example 3 was obtained in the same manner as in Example 1. In this adhesive composition, relative to 100 parts by weight of 30% ethyl acetate solution of the adhesive polymer formed by the copolymer of 58 parts by weight of 2-ethylhexyl acrylate, 38 parts by weight of butyl acrylate, and 4 parts by weight of 2-hydroxyethyl acrylate, adding In addition, 1.2 parts by weight of an isocyanate curing agent (manufactured by TOSOH CORPORATION, trade name: Coronate (registered trademark) HX) was mixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com