Novel wire and preparation method thereof

A wire, a new type of technology, applied in the direction of conductors, manufacturing wire harnesses, insulated conductors, etc., can solve problems such as maintenance troubles and difficulties, and achieve the effects of low production costs, simple procedures, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

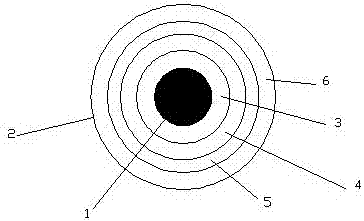

[0032] see figure 1 , the new type of wire described in this embodiment includes a conductive core 1 and a protective sheath 2, the protective sheath 2 is wrapped around the conductive core 1, and the protective sheath 2 is sequentially provided with an insulating layer 3 and a flame-retardant layer from the inside to the outside. 4. Shielding layer 5, outer protective layer 6; the conductive core 1 includes the following components in parts by weight: 5 parts of carbon fiber rods, 50 parts of copper, 12 parts of zinc, 10 parts of manganese, 5 parts of aluminum, and 3 parts of silver nanowires part; the insulating layer 3 is made of modified ethylene propylene insulation or cold-resistant soft elastomer, with a thickness of 0.1mm; the flame-retardant layer 4 is made of halogen-free low-smoke flame-retardant thermoplastic polyester elastomer TPEE, with a thickness of 0.2mm; The shielding layer 5 adopts a tin-plated soft-through weaving method with a weaving density of 85%; the ...

Embodiment 2

[0042] see figure 1 , the new type of wire described in this embodiment includes a conductive core 1 and a protective sheath 2, the protective sheath 2 is wrapped around the conductive core 1, and the protective sheath 2 is sequentially provided with an insulating layer 3 and a flame-retardant layer from the inside to the outside. 4. Shielding layer 5, outer protective layer 6; the conductive core 1 includes the following components in parts by weight: 10 parts of carbon fiber rods, 70 parts of copper, 15 parts of zinc, 20 parts of manganese, 10 parts of aluminum, and 5 parts of silver nanowires part; the insulating layer 3 is made of modified ethylene propylene insulation or cold-resistant soft elastomer, with a thickness of 1mm; the flame-retardant layer 4 is made of halogen-free low-smoke flame-retardant thermoplastic polyester elastomer TPEE, with a thickness of 0.5mm; The shielding layer 5 adopts a tin-plated soft-through weaving method with a weaving density of 90%; the ...

Embodiment 3

[0051] see figure 1, the new type of wire described in this embodiment includes a conductive core 1 and a protective sheath 2, the protective sheath 2 is wrapped around the conductive core 1, and the protective sheath 2 is sequentially provided with an insulating layer 3 and a flame-retardant layer from the inside to the outside. 4. Shielding layer 5, outer protective layer 6; the conductive core 1 includes the following components in parts by weight: 6 parts of carbon fiber rods, 55 parts of copper, 13 parts of zinc, 12 parts of manganese, 5 parts of aluminum, and 3.5 parts of silver nanowires part; the insulating layer 3 is made of modified ethylene propylene insulation or cold-resistant soft elastomer, with a thickness of 0.1mm; the flame-retardant layer 4 is made of halogen-free low-smoke flame-retardant thermoplastic polyester elastomer TPEE, with a thickness of 0.2mm; The shielding layer 5 adopts a tin-plated soft-through weaving method with a weaving density of 85%; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com