Gas discharging type plasma density automatic regulation and control system and device

A plasma and gas discharge technology, applied in the direction of plasma, electrical components, etc., to achieve the effect of improving experimental efficiency and avoiding adjustment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

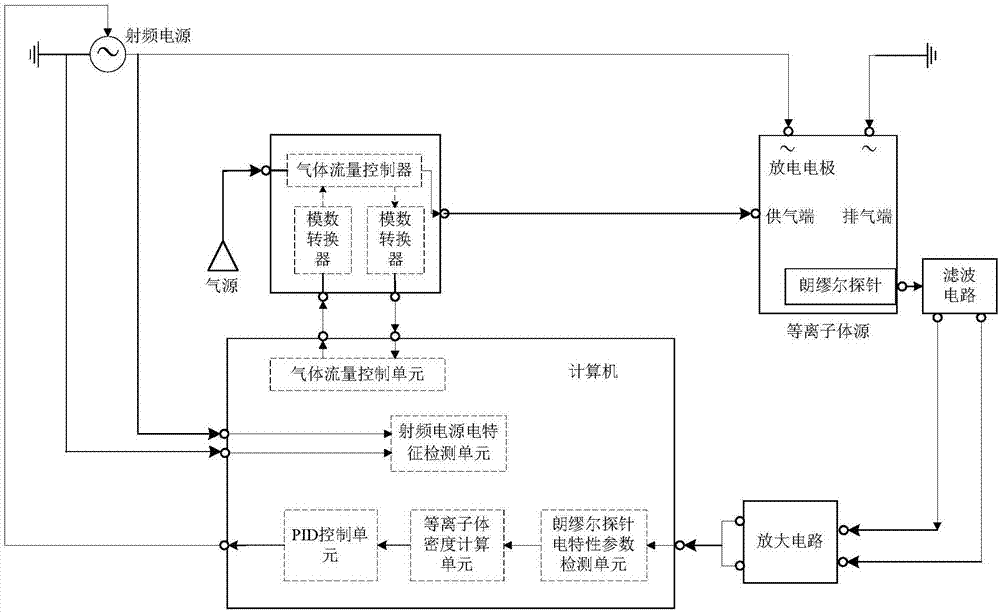

[0039] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0040] A gas discharge type plasma density automatic control system is a system for monitoring discharge parameters and density control of a plasma source. The plasma source (inductively coupled plasma source, ICP) is supplied with gas through a gas source, and the gas The flow controller is set between the gas source and the gas supply end of the plasma source to control the gas source flow of the plasma source; the plasma source is exhausted through a mechanical pump; a Langmuir probe is installed inside the plasma source , the radio frequency power supply supplies power to the discharge electrode of the plasma source;

[0041] The gas discharge type plasma density automatic control system includes:

[0042] The gas flow control unit is used to detect the state of the gas flow controller, and control the gas flow controller to supply gas to the plasma source;

[0043] The Langmuir pro...

specific Embodiment approach 2

[0047] The gas discharge type plasma density automatic control system described in this embodiment also includes:

[0048] The radio frequency power supply electrical characteristic detection unit is used to collect the voltage and current signals of the radio frequency power supply, and judge whether the radio frequency power supply is working normally and the discharge stability of the plasma. The normal voltage and current of the RF power supply can be compared with the voltage and current signals of the collected RF power supply to determine whether the RF power supply is working normally; the discharge stability can be judged by the stability of the current signal of the RF power supply.

[0049] Other units and modules are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] The radio frequency power supply electrical characteristic detection unit described in this embodiment includes:

[0052] The radio frequency power supply voltage detection module is used to detect the voltage signal of the radio frequency power supply;

[0053] The radio frequency power supply current detection module is used to detect the current signal of the radio frequency power supply;

[0054] The electrical characteristic detection module is used for judging the discharge stability of the radio frequency power supply and judging whether the radio frequency power supply is working normally.

[0055] Other units and modules are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com