Method for treating desulfurization wastewater in power plant

A desulfurization wastewater and treatment method technology, applied in the field of environmental engineering, can solve the problems of easy scaling of membranes and evaporators, high hardness of desulfurization wastewater, cumbersome operation, etc., to solve scaling problems, reduce scale, and reduce concentrated water volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

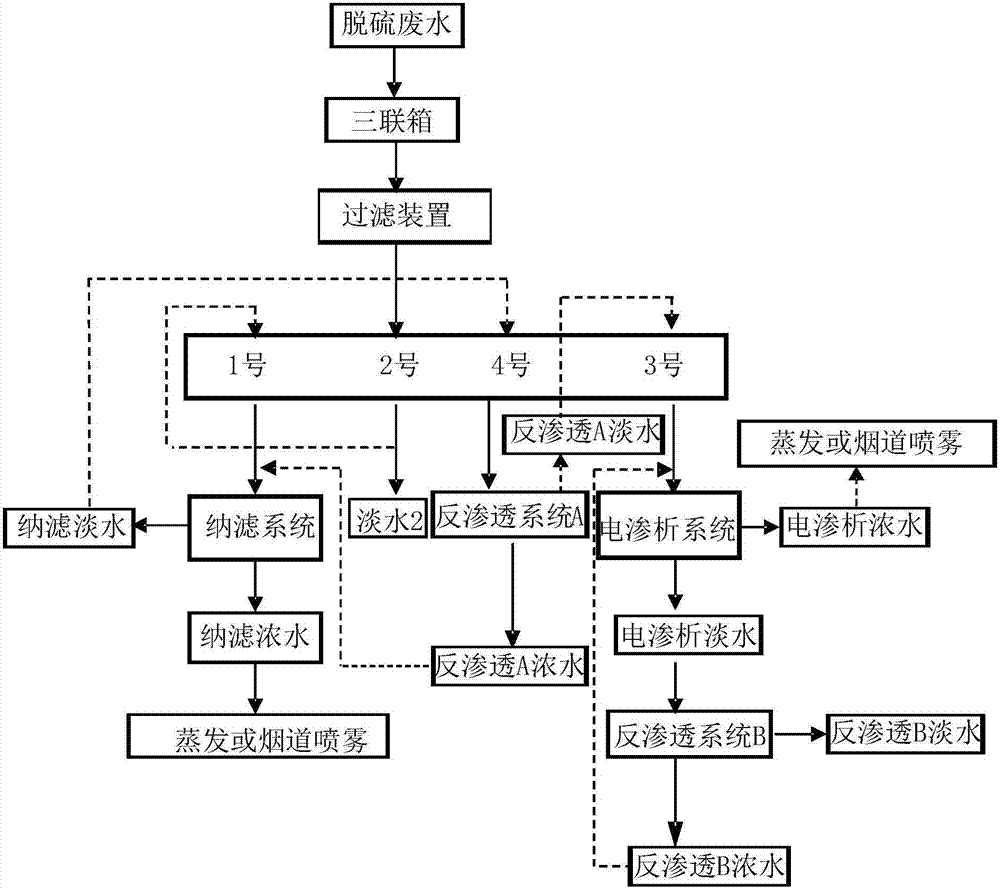

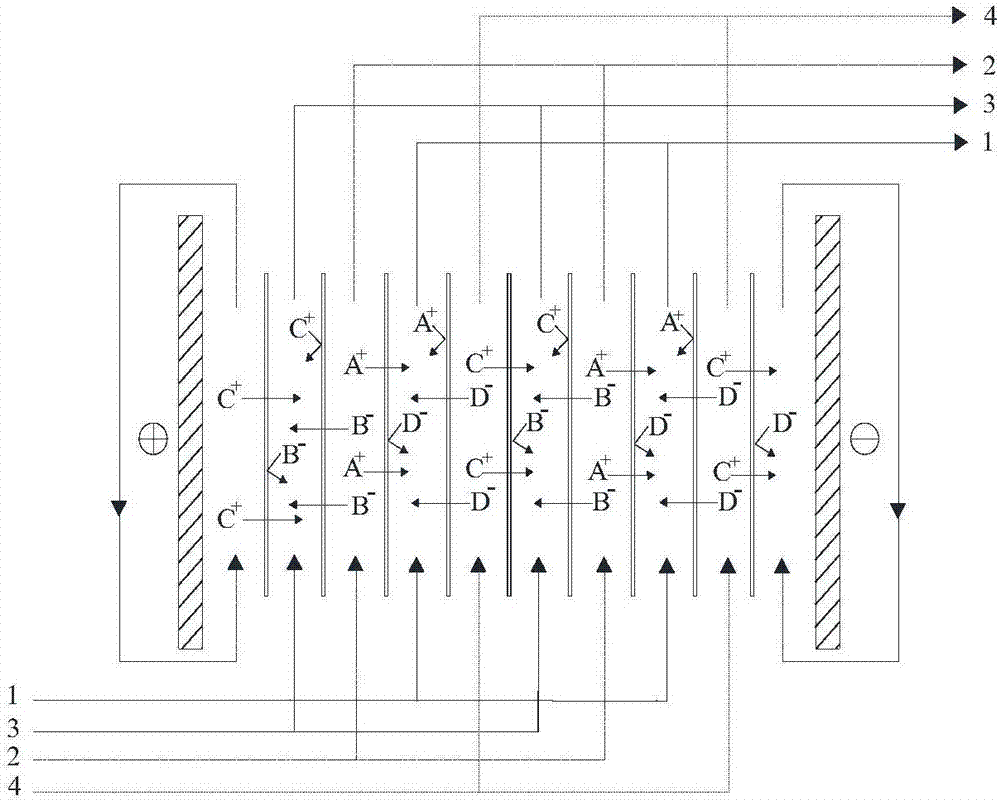

[0032] The invention provides a method for treating desulfurization wastewater of a power plant, which uses the world's first electric-driven ion combination process to realize the separation and recombination of calcium and sulfate radicals in calcium sulfate. Solve the scaling problem of calcium sulfate on the membrane and evaporator by recombining the scaling calcium sulfate ion, then use the electrodialysis process to concentrate the wastewater to 20%, and then realize the purification of the wastewater by mechanical evaporation crystallization or flue spraying process Ultimately zero emissions. Next, the method for treating desulfurization wastewater of a power plant according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com