Inner circular efficient compost system

An internal circulation and composting technology, which is applied in the direction of organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of composting prone to hypoxia, increased production costs, and surrounding environmental pollution, so as to shorten compost maturity time, reduce mechanical loss, Effect of reducing nitrogen volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

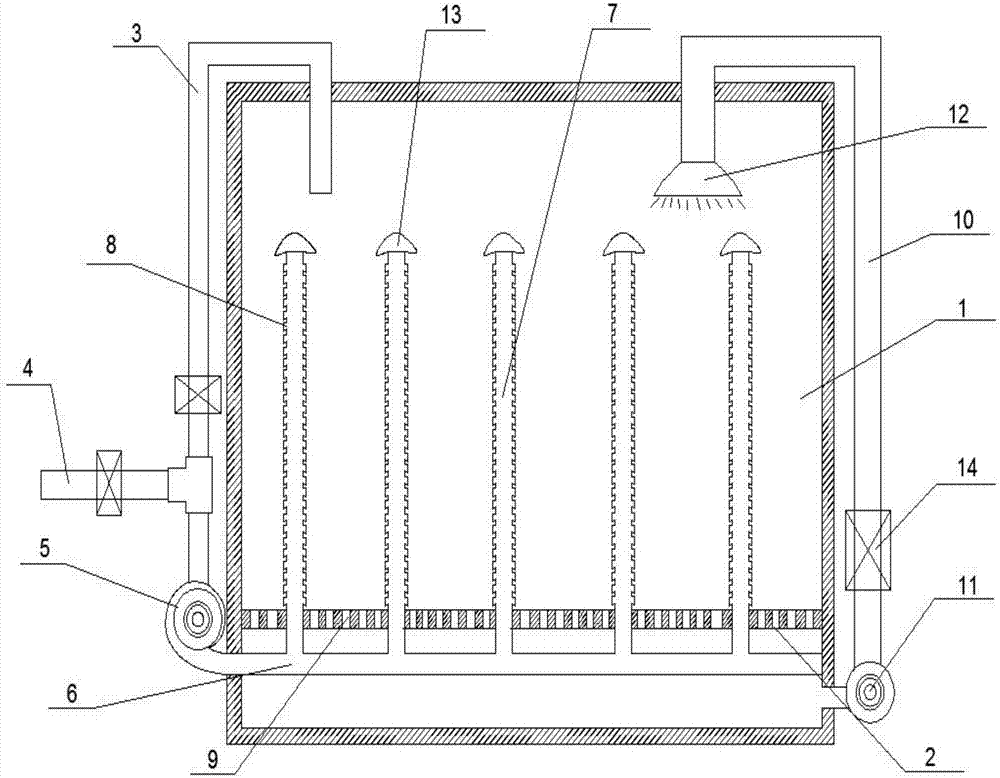

[0031] An internal circulation high-efficiency composting system, comprising a composting chamber 1, a filtrate plate 2 is arranged in the composting chamber 1, an exhaust gas conduit 3 is arranged above the composting chamber 1, and the exhaust gas conduit 3 and the oxygen introduction conduit 4 are respectively connected with a The air inlet of the blower 5 is connected, and the air outlet of the blower 5 is connected with the air guide main pipe 6, and the air guide main pipe 6 extends from the outside through the side of the composting chamber 1 to the bottom of the filtrate plate 2, and the air guide main pipe There are multiple groups of 6, evenly distributed below the filtrate plate 2; the air guide main pipe 6 is provided with a plurality of air guide branch pipes 7, and the air guide branch pipes 7 are arranged vertically through the filtrate plate 2, and the air guide branch pipes 7 side walls are provided with a plurality of aeration ports 8, thereby forming an air c...

Embodiment 2

[0034] The difference between this embodiment and the internal circulation high-efficiency composting system of Embodiment 1 is that: the aeration port 8 extends outwards vertically to the air guide branch pipe 7 to form a right-angled trapezoid in cross-section, wherein the bottom end of the aeration port 8 is inclined downward , to guide the airflow to fully contact the compost material; the aeration port 8 is provided with a ball to prevent the aeration port 8 on each air guide pipe 7 from being blocked by the compost material, and to ensure that the gas is evenly supplied to the inside of the thicker compost material .

Embodiment 3

[0036] The difference between this embodiment and the internal circulation high-efficiency composting system of the above-mentioned embodiment is only that: the exhaust gas conduit 3, the oxygen introduction conduit 4, the gas guide main pipe 6, and the filtrate return pipe 10 are all provided with a solenoid valve 14 for flow control. The composting chamber 1 is provided with an environment sensing device, the environment sensing device is an oxygen content sensor, a temperature sensor and / or a humidity sensor, and the solenoid valve 14, the blower 5, and the environment sensing device are connected with a controller. Use the environmental sensing device to monitor the internal state of the composting chamber 1, and control the opening and closing of each solenoid valve 14 through the controller according to the internal temperature and humidity of the composting chamber 1, the particle size of the compost material, the water level, and the tightness, so that the composting env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com