Patents

Literature

72results about How to "Reduce fertilizer efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof

InactiveCN106867945AIncrease resistanceImprove enrichment capacityBacteriaContaminated soil reclamationMicroorganismResource utilization

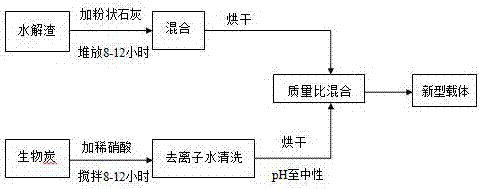

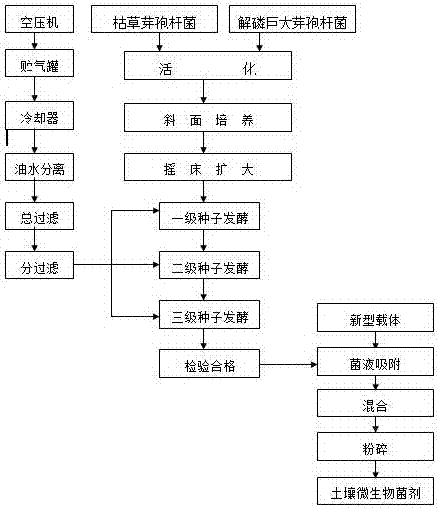

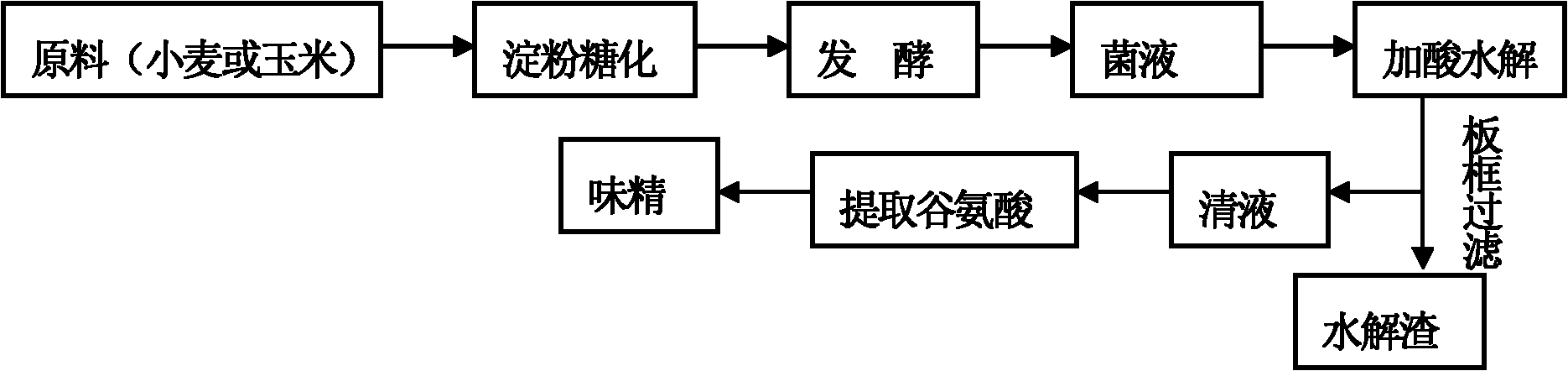

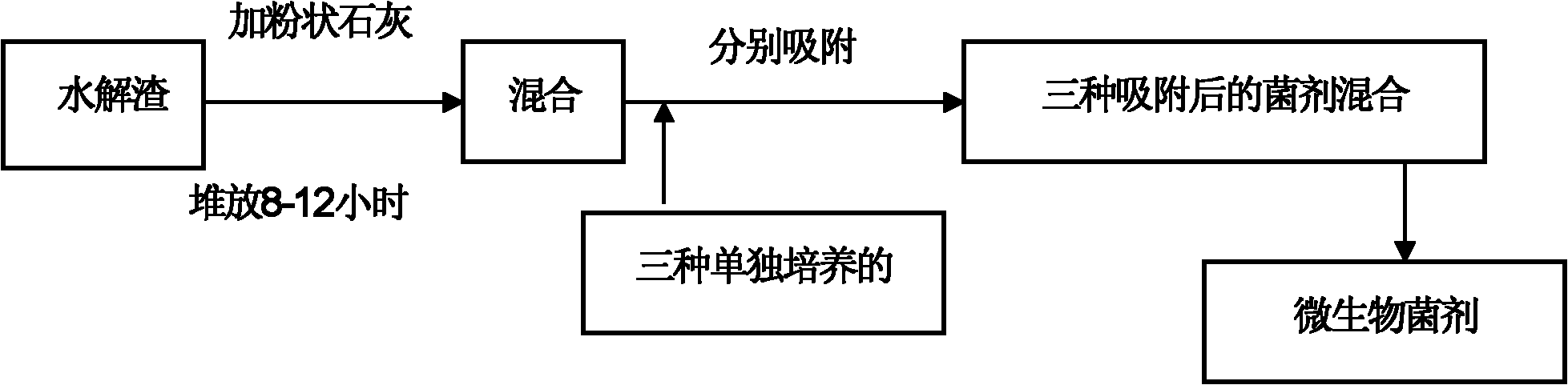

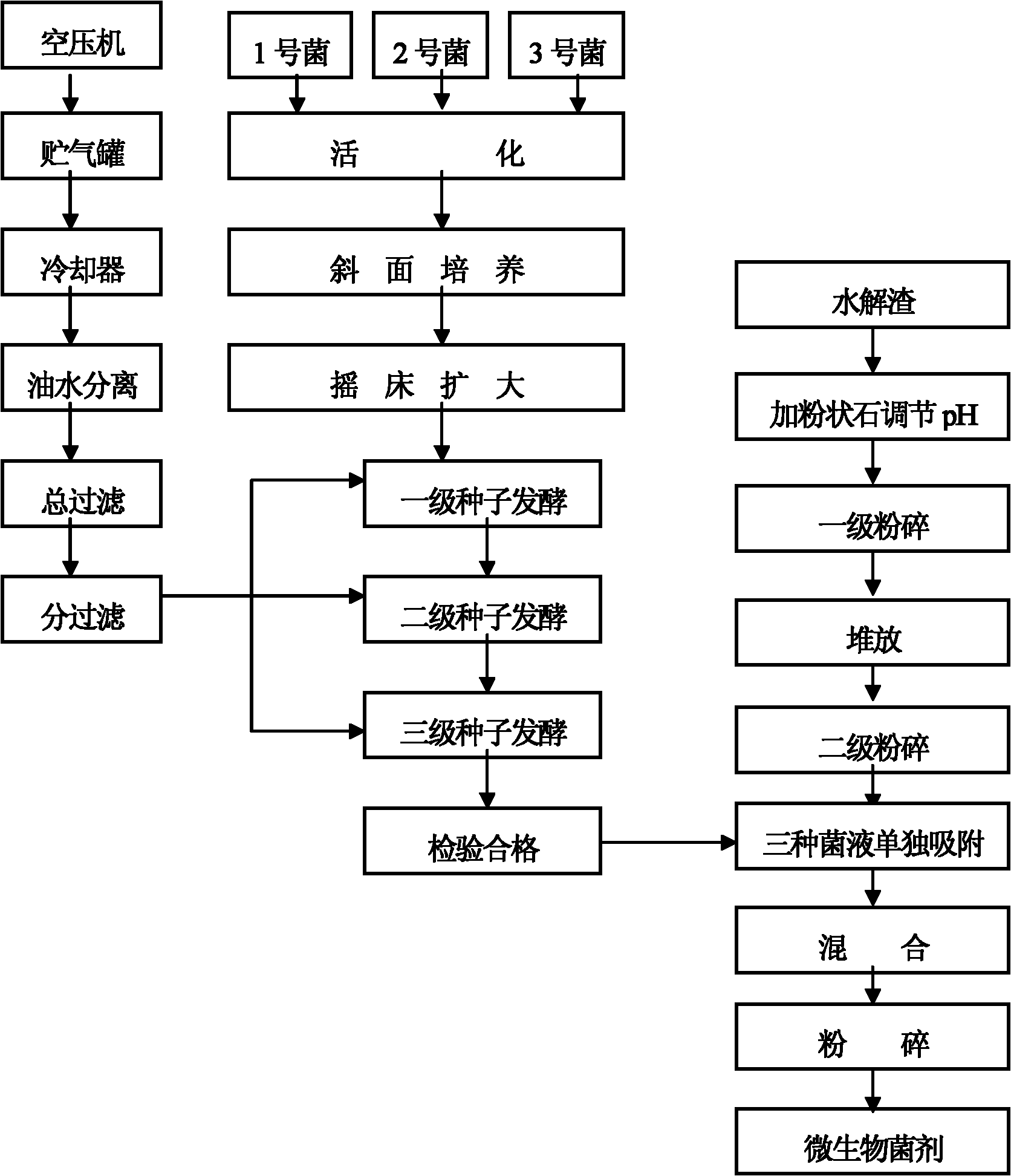

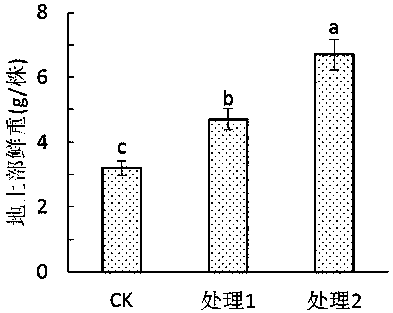

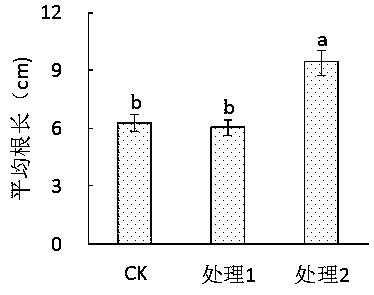

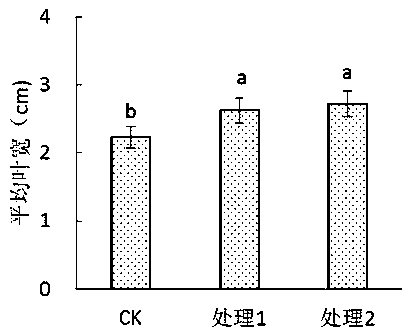

The invention discloses a microorganism passivator for repairing heavy metal pollution of soil and preparation and application thereof. A preparing method comprises the steps of fermentation and adsorption of strains. Specifically, bacteria solutions obtained after fermentation of bacillus megateriumvar.phosphaticum and bacillus subtilis LVLE-14 are mixed in proportion, then adsorption is conducted by means of a special adsorption carrier, and then mixing and smashing are conducted to obtain the microorganism passivator. The adsorption carrier comprises hydrolysis residues and biochar which are mixed and smashed according to a certain mass ratio. By the adoption of the microorganism passivator for repairing heavy metal pollution of soil, the content of available heavy metals in soil can be effectively reduced, and the number of microbial populations and plant yield are increased greatly. The method for repairing heavy metal pollution of soil by means of the microorganism passivator is in-situ repair, operation is easy, the cost is low, and industrialized implementation can be easily achieved; furthermore, the repairing effect is good, soil fertility can not be damaged, and the utilization rate of resources can be increased.

Owner:SHANGHAI LVLE BIO TECH

Medical fertilizer and method for preparing the same

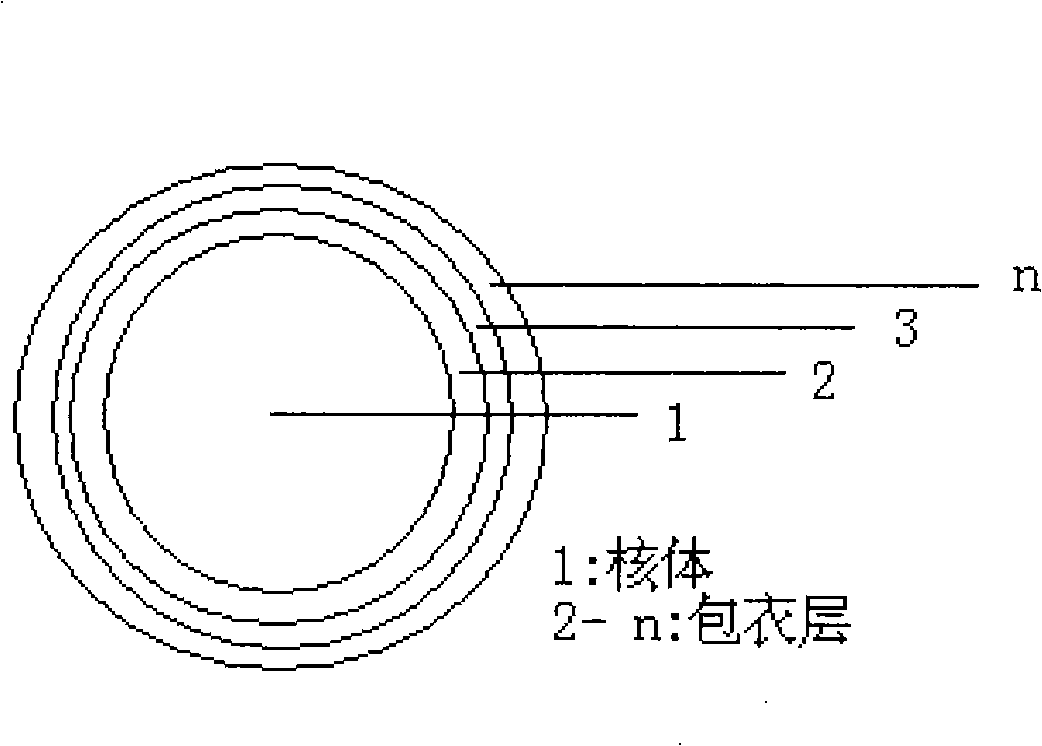

InactiveCN101302130AReduce fertilizer efficiencyReduce efficacyUrea compound fertilisersPotassium fertilisersChemistryUrea

The invention relates to a medical fertilizer and a method for making the same. The medical fertilizer has granular shape and consists of a kernel body and at least one lagging cover, wherein, the kernel body is granular substance and the lagging cover is powder or liquid. The medical fertilizer and the method for making the same ensure that the farm chemical and the fertilizer can sufficiently work and various effective compositions are not affected; the particles such as urea are taken as kernel part and the powder or liquid farm chemical or the fertilizer, etc. are used to produce the medical fertilizer in a lagging cover way.

Owner:ZHENGZHOU UNIV +1

Special Ginseng composite mixed fertilizer

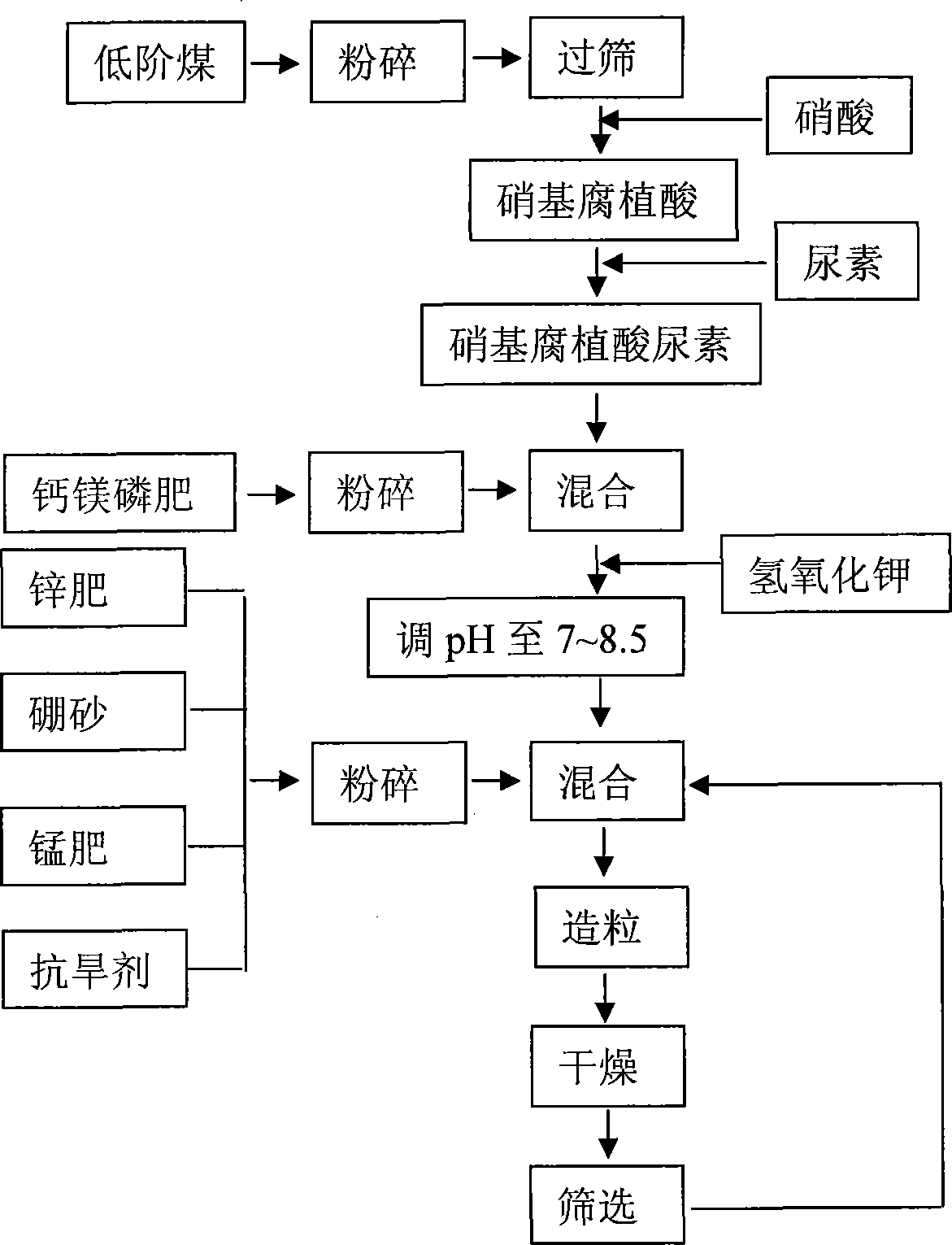

InactiveCN101074179AIncrease profitIncrease the granular structureOrganic fertilisersFertilizer mixturesSoil sciencePotassium hydroxide

A special ginseng composite fertilizer and its production are disclosed. The process is carried out by complexing humus acid with urea to form long-lasting urea as controlled-release fertilizer, adding into caustic potash while dissolving under basic condition and adding into phosphate fertilizer, magnesium fertilizer, boron fertilizer, zinc fertilizer, manganese fertilizer and drought-resisting agent. It can supply ginseng and microbial pool with nutrients, improve ginseng root development and increase its quality and pest-resistance. It's efficient, simple, stable, convenient and cheap.

Owner:NORTHEAST NORMAL UNIVERSITY

Method for producing defluorinated ammonium phosphate

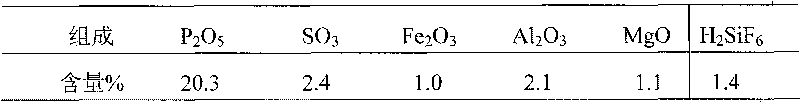

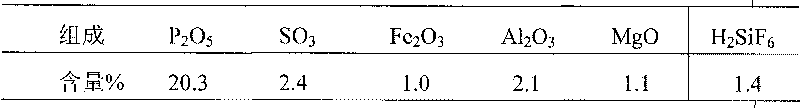

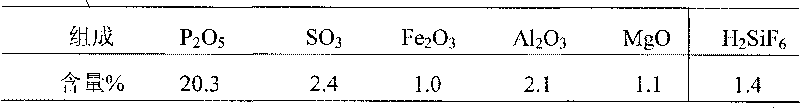

InactiveCN101708832ATake advantage ofAvoid lostPhosphatesSilicon halogen compoundsPhosphoric acidPotassium

The invention relates to a method for producing defluorinated ammonium phosphate and belongs to the technical field of chemical production. In the method, a fluosilicic acid in a wet-process phosphoric acid is made to generate potassium (or sodium) fluosilicate precipitate in a mode of adding soluble potassium (or sodium) salt, potassium (or sodium) fluosilicate is a by-product after the potassium (or sodium) fluosilicate precipitate is separated, the defluorinated wet-process phosphoric acid is subjected to neutralization reaction with gas ammonia, and a neutralized slurry is prepared into the defluorinated ammonium phosphate by the steps of concentrating, drying, packaging and the like. The method for producing the defluorinated ammonium phosphate is mainly used in the field of fertilizer production.

Owner:SHANDONG HONGRI ACRON CHEM

Multifunctional soil maturing agent and preparation method thereof

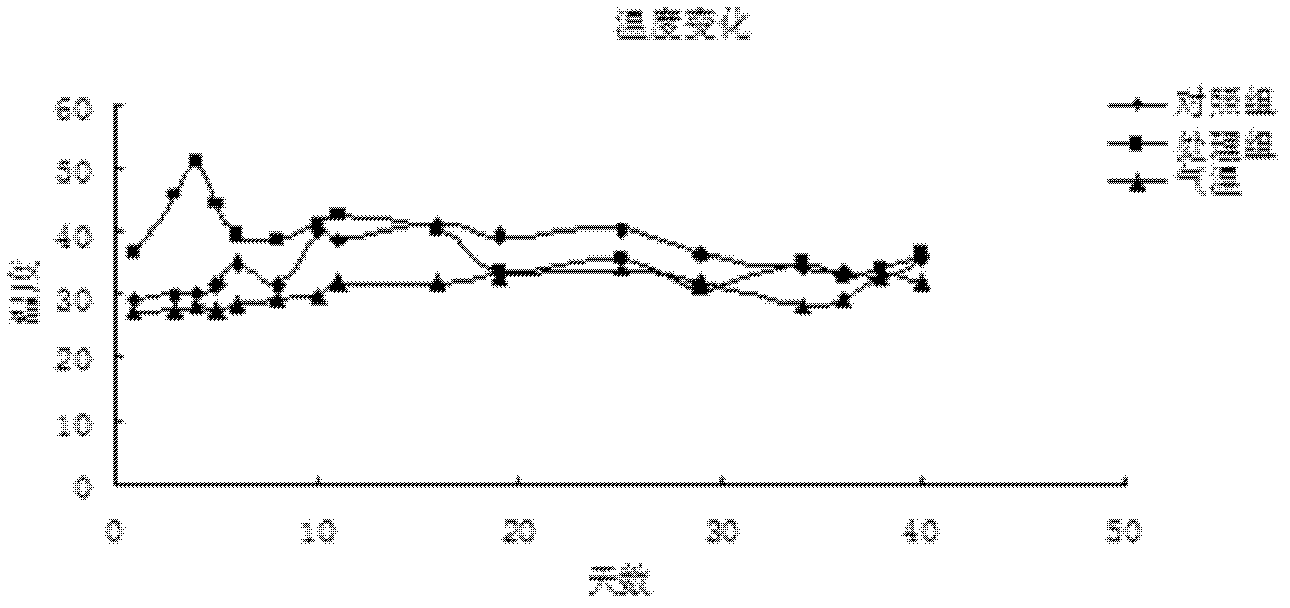

InactiveCN102674917AAppearance darkSoft appearanceBio-organic fraction processingOrganic fertiliser preparationEvery Three DaysSoil conditioner

Disclosed are multifunctional soil maturing agent and a preparation method thereof. The soil maturing agent comprises biochar and poultry excrement in a weight ratio of 10:3-10:5. The preparation method includes: mixing the biochar and the poultry excrement proportionally, well mixing, and adjusting water content to about 60%; and covering the mixture with a thin layer of biochar, turning compost each day 20 days before composting, keeping the water content of 60% unchanged, turning the compost once every three days from the twentieth day to the thirtieth day, turning the compost once a week, and avoiding sunlight and rain. The compost is made of mixture of biochar and farm poultry excrements such as pig excrement. The problems of odor, long formation time and low fertilizer efficiency of traditional compost are solved. The poultry excrements can be also be used fully, and waste is turned into wealth. Composted products can be used as oil conditioner / maturing agent and gardening medium. The multifunctional soil maturing agent has promising market prospect.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

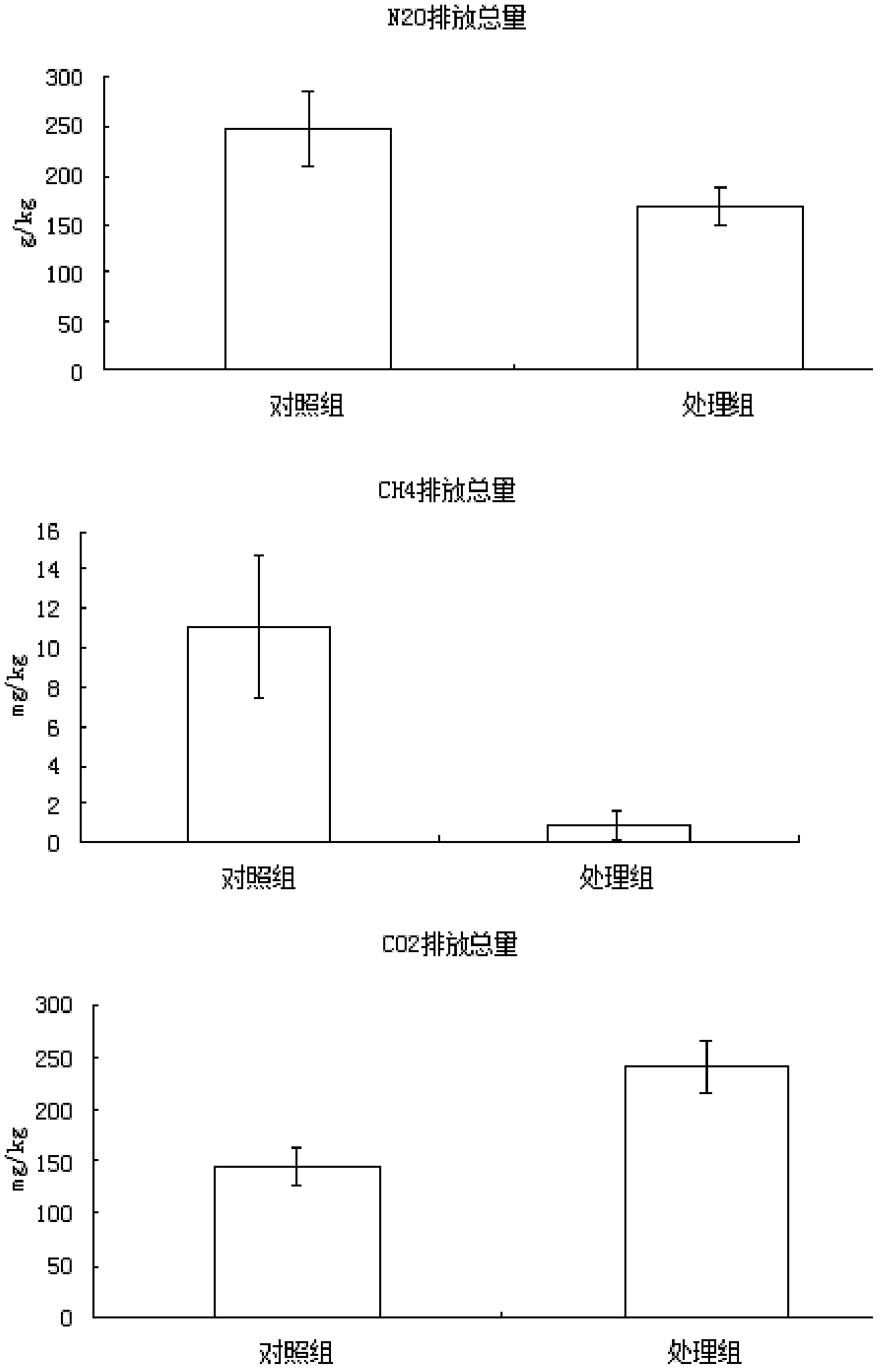

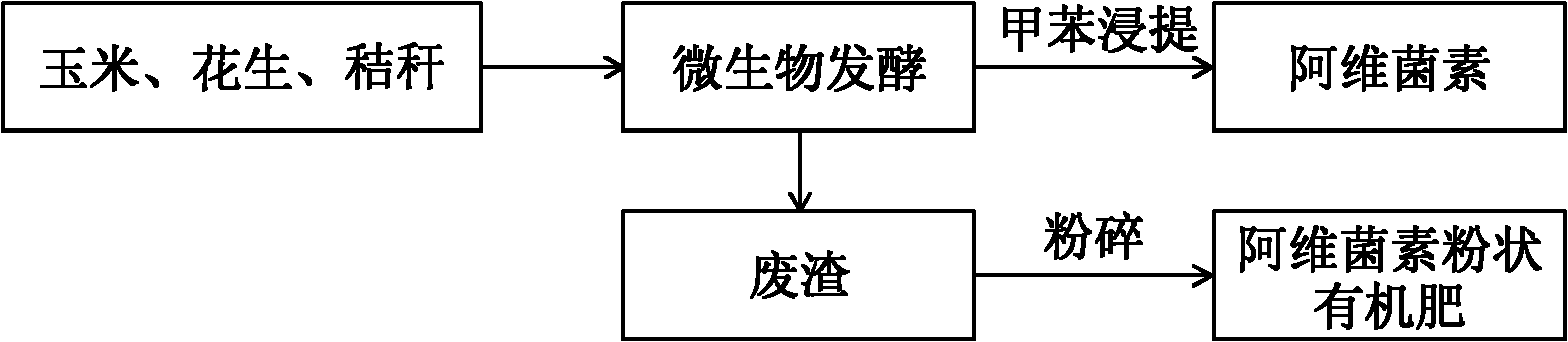

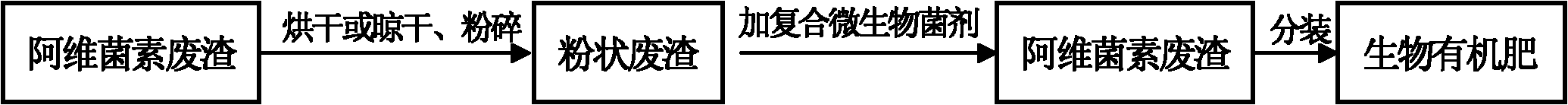

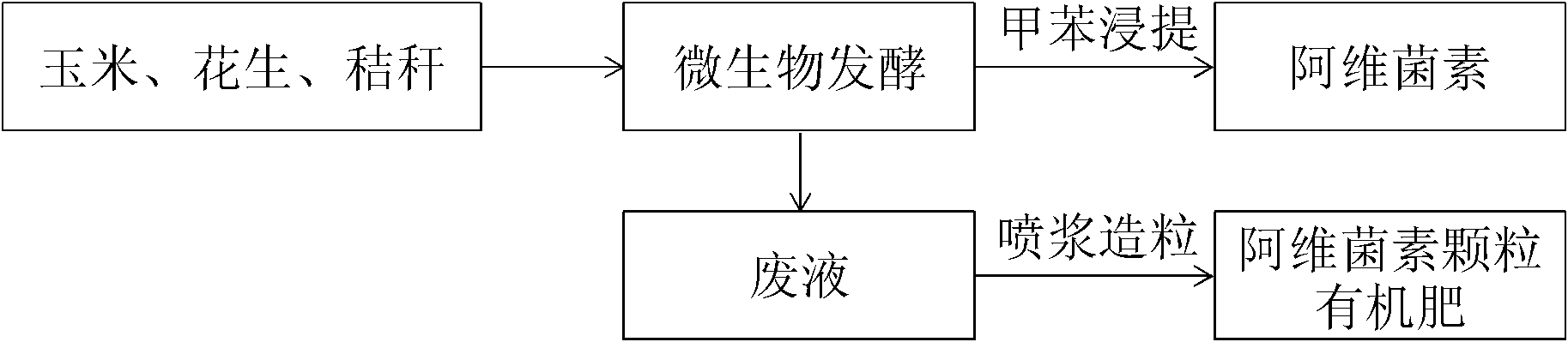

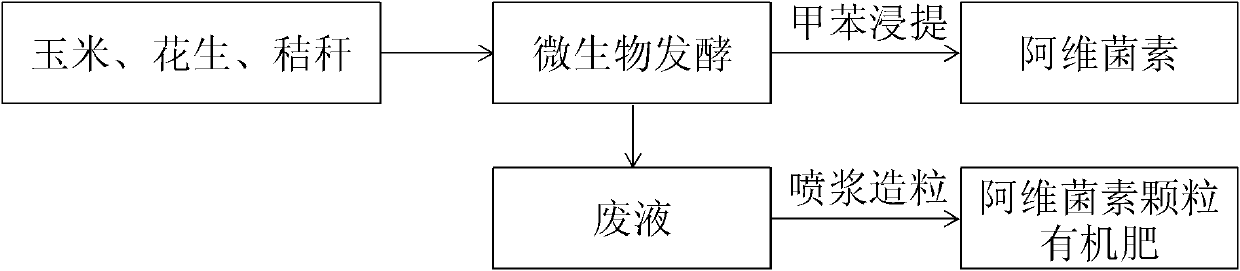

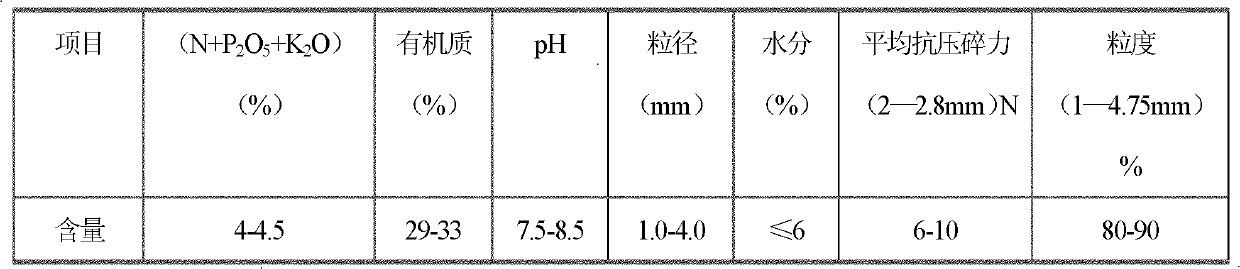

Production method of biological organic fertilizer containing Avermectins

InactiveCN102173887AHigh technical contentGood application effectOrganic fertilisersMicroorganismBacillus megaterium

The invention provides a method for producing a biological organic fertilizer from Avermectins waste slag. The method comprises the following steps: respectively carrying out independent fermentation production on Bacillus subtilis, Bacillus megaterium and Bacillus mucilaginosus; respectively adsorbing the fermented bacterium liquids with rice hull powder; mixing the three adsorbed single microbial inoculums according to a mass ratio of (0.1-8):(0.1-4):(0.1-4), and crushing to obtain a compound microbial inoculum; and treating waste slag obtained in the Avermectins production process, and adding the compound microbial inoculum which accounts for 2-15% of the total weight to the waste slag, thus obtaining the required biological organic fertilizer. The method has a simple production process, is beneficial to the large-scale production, and provides a way for the recycling of Avermectins waste slag.

Owner:SHANGHAI LVLE BIO TECH

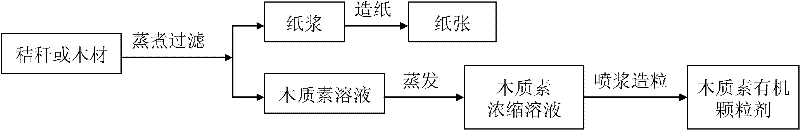

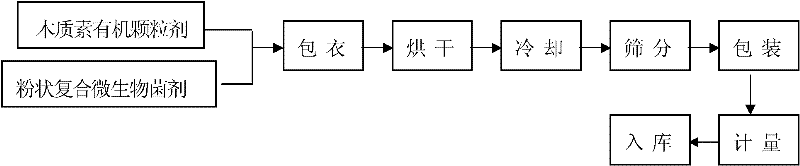

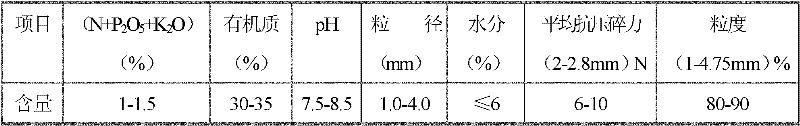

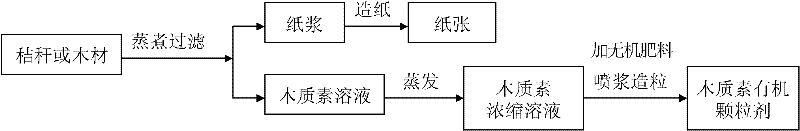

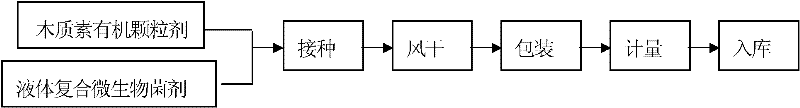

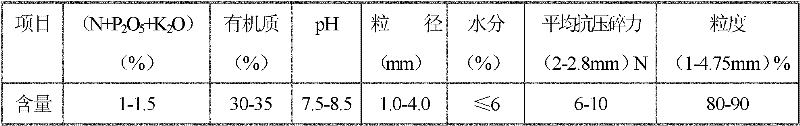

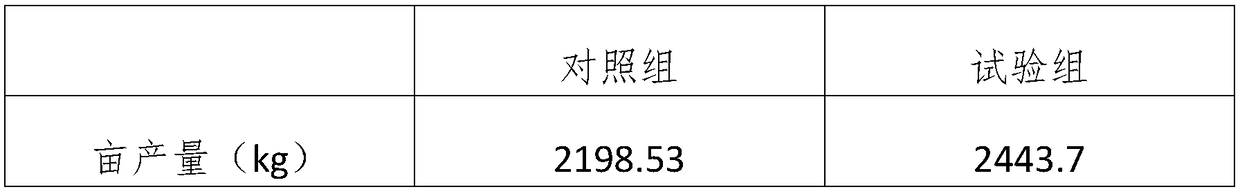

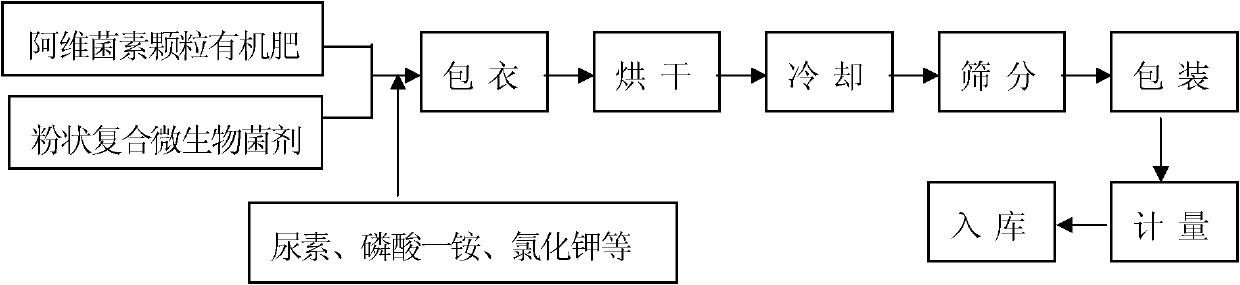

Method for producing bio-organic fertilizer by performing spraying granulation

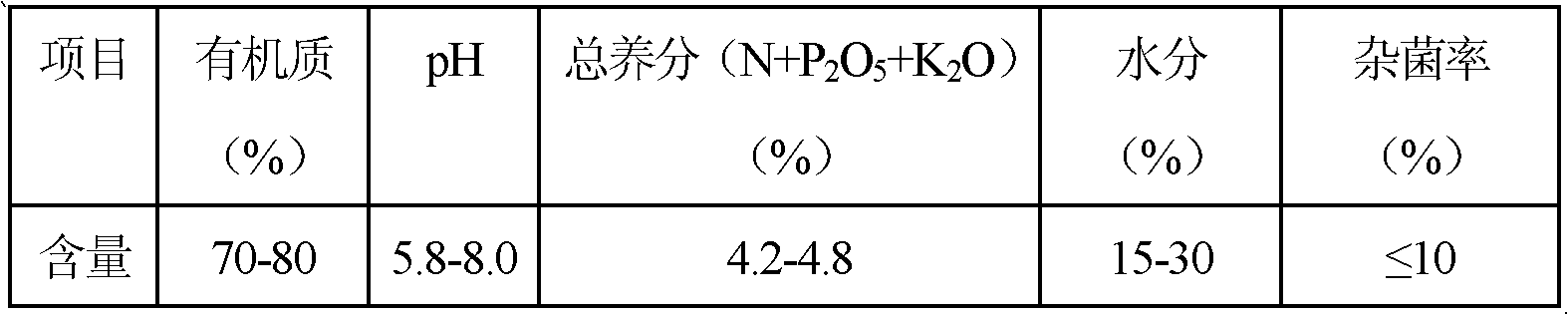

InactiveCN102442846AFlat surfaceHigh technical contentFertiliser formsOrganic fertilisersChemistryOrganic fertilizer

The invention provides a method for producing a bio-organic fertilizer by performing spraying granulation. The method comprises the following steps of: preparing a solid inoculant; granulating a lignin waste liquor into organic granules; compounding the organic granules with solid powder, wherein a powdery inoculant is added in an amount of 5-15 percent by weight based on the total weight of a finished compound microbial fertilizer; and mixing, granulating and drying under the condition that the material temperature in a drying barrel is not higher than 80 DEG C. In the invention, a new path is opened, the convection is broken, a production method of the granular bio-organic fertilizer is partitioned into an organic granule granulating step and an organic granule coating step, a certain viable count in the bio-organic fertilizer is ensured simultaneously, breakthrough of the bio-organic fertilizer product from powdery and disc-drum granulation to a spraying granulation process is realized, and foundations are laid for enhancing the commodity, effectiveness and area popularization of the bio-organic fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

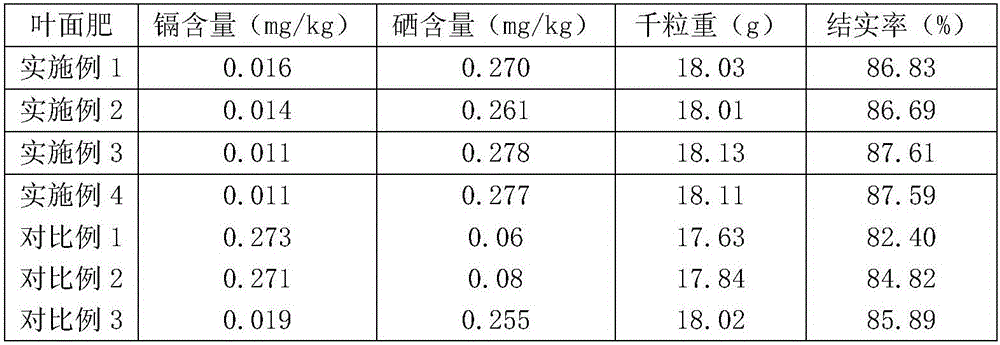

Selenium-rich cadmium-reducing leaf fertilizer special for paddy

ActiveCN106748274AIncrease selenium contentReduce the content of harmful substancesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumMonopotassium phosphate

The invention belongs to the technical field of a paddy planting fertilizer and specifically relates to a selenium-rich cadmium-reducing leaf fertilizer special for paddy. The selenium-rich cadmium-reducing leaf fertilizer special for paddy is composed of citric acid monohydrate, sodium selenite, urea, potassium chloride, monopotassium phosphate, soluble microelement compound, momordica grosvenori and herb of alligator alternanthera. The leaf fertilizer can increase the absorbing conversion rate of the paddy for selenium, has an excellent cadmium-impeding performance, is rich in nutrition and is easily absorbed. After the fertilizer is applied to the paddy, the selenium-rich cadmium-reducing efficiency of the leaf fertilizer is higher, the effect is stable and the yield of the paddy is high.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Myrica rubra dongkui planting method

InactiveCN104938275AStrong antibioticImprove disease resistanceCultivating equipmentsMain branchSoil properties

The invention relates to the technical field of myrica rubra planting, in particular to a myrica rubra dongkui planting method. The myrica rubra dongkui planting method is characterized by comprising the following steps of planting, wherein planting and fertilization are carried out from the last ten days of February to the middle ten days of March, and 38-42 strains are planted per mu; application of special fertilizer, wherein the special fertilizer of 200-300 g is applied for saplings once between September and October, the special fertilizer is applied once in June of the next year and January of the third year, and the special fertilizer is applied three times in the whole year from the fourth year after fruitage; pruning, wherein the position 60-70 cm high of a trunk is cut back after planting, three to four buds which are distributed evenly are selected as main branches, the interval between the main branches is kept 15-20 cm, the opening angle is 45-60 degrees, the crown is pressed, and the crown keeps from 2.8 meters to 3.2 meters; pest control and prevention. The density is reasonable, management and fertilization are reasonable, the fertilizer nutrients are comprehensive, the capacity of providing the fertilizer is high, the soil property can be improved, and therefore the myrica rubra dongkui is high in stress resistance and yield.

Owner:郎溪县建平镇玲珑苗木种植家庭农场

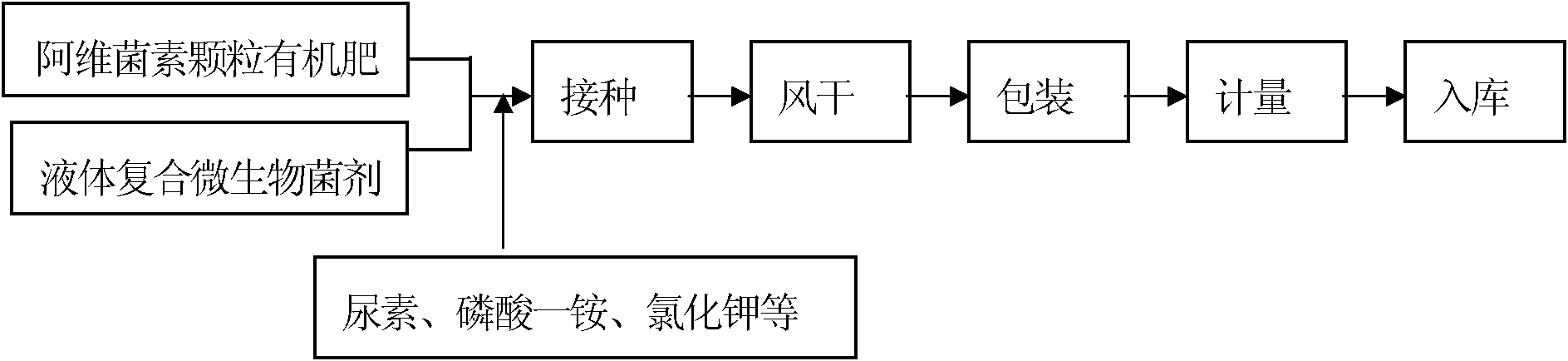

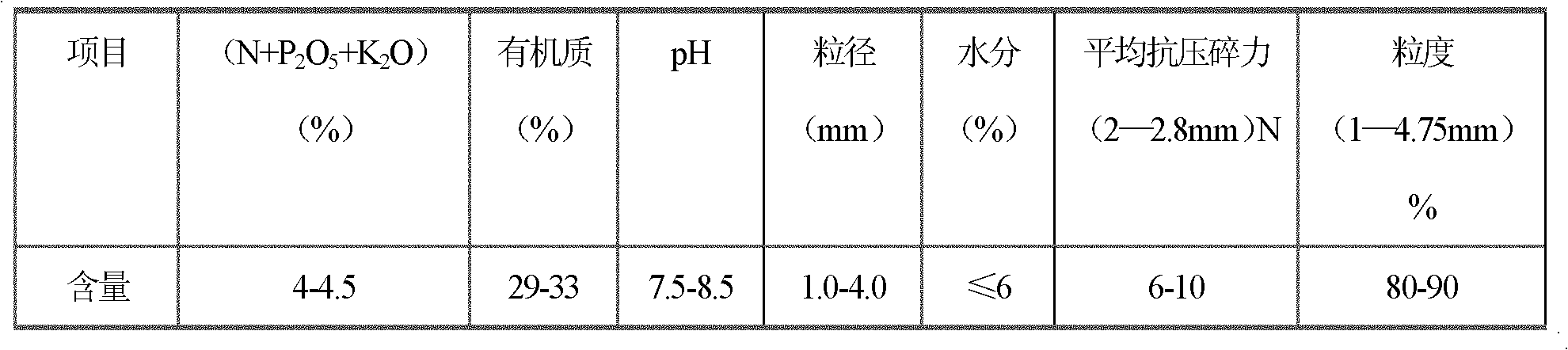

Method for producing compound microbial fertilizer with insecticidal effect

InactiveCN102040430AReduce manufacturing costImprove product qualityFertilizer mixturesMicrobial agentInorganic fertilizer

The invention provides a method for producing a compound microbial fertilizer with insecticidal effect, comprising the following steps: preparing liquid microbial agent; adding waste abamectin liquid to inorganic fertilizer, and granulating the inorganic fertilizer into granular organic fertilizer; compounding the granular organic fertilizer and the liquid microbial agent which is 0.5-1.5 percent of the weight of the finished product of the compound microbial fertilizer; and airing or drying. The invention breaks the normal method for producing the compound microbial fertilizer and provides a novel method for producing the granular compound microbial fertilizer by granulating the inorganic fertilizer into the organic fertilizer and coating the liquid microbial agent by the granular organic fertilizer. The powdery compound microbial fertilizer is replaced by the granular compound microbial fertilizer, and the granular compound microbial fertilizer has a certain activity, thus a good foundation is laid for popularizing the granular compound microbial fertilizer on a large scale. The invention also provides a method for recycling the waste abamectin liquid.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

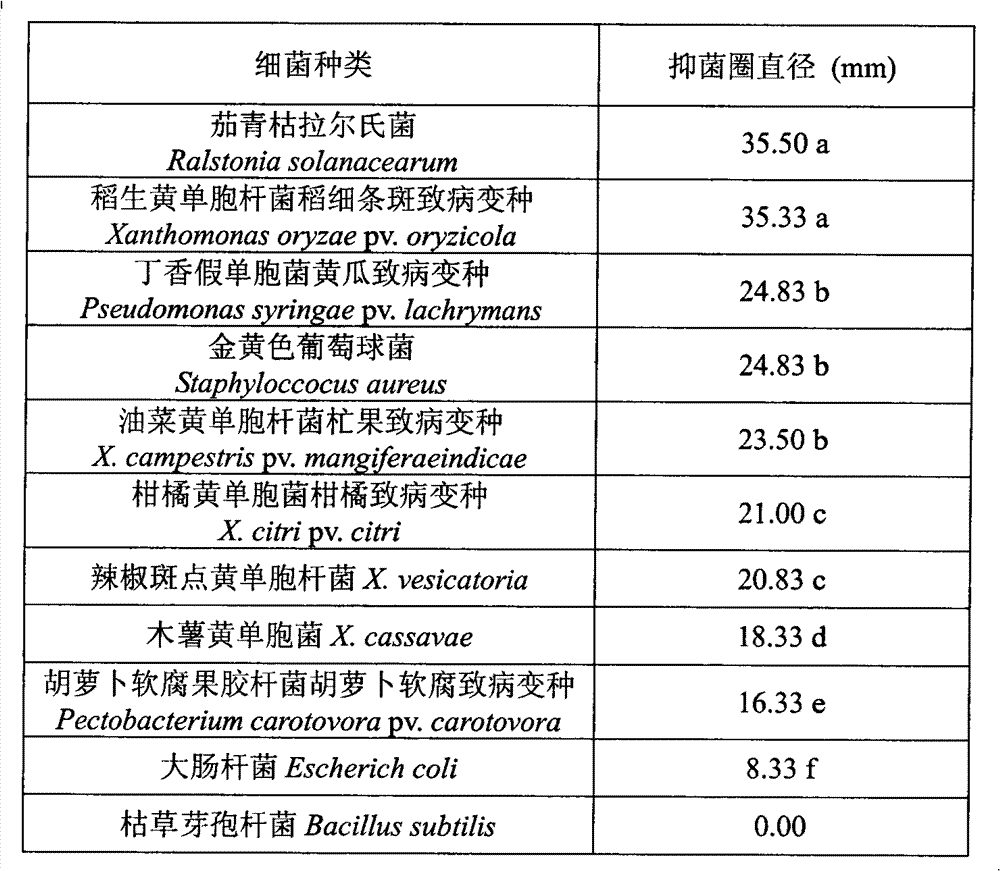

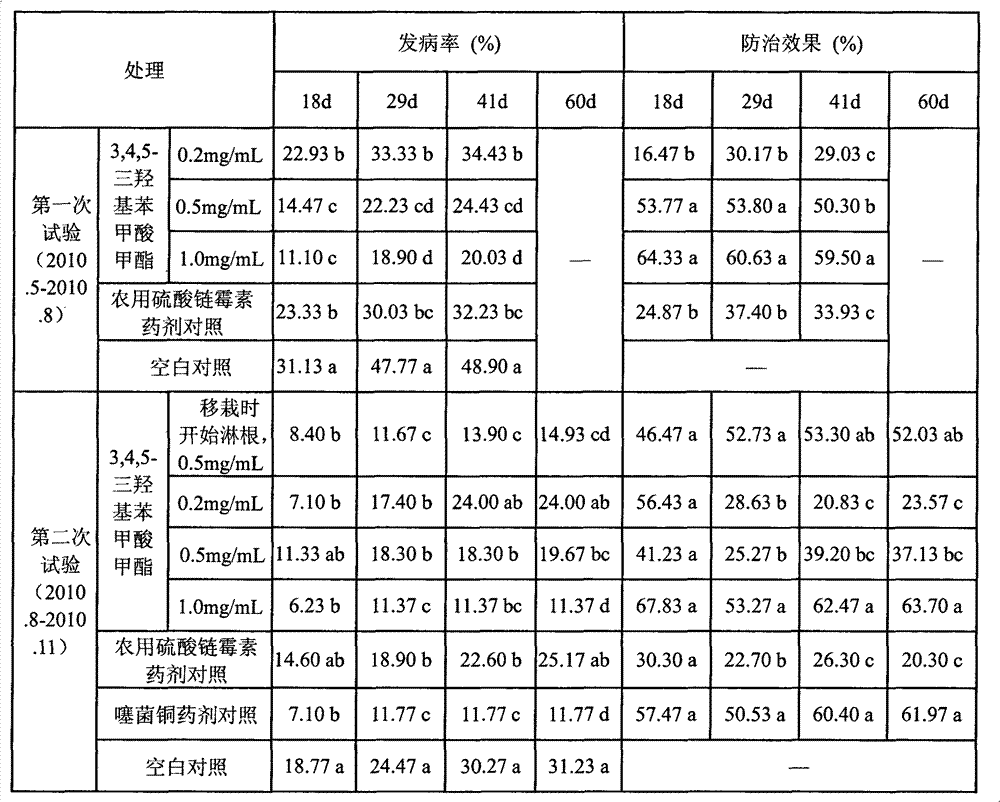

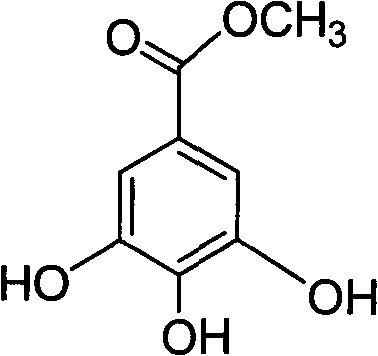

Application method of plant-derived fungicide in plant disease prevention and control

InactiveCN102783486AWide variety of sourcesReduce manufacturing costBiocideFungicidesDiseaseBacterial disease

The present invention relates to an application method of a plant natural compound in plant disease prevention and control, and specifically to an application method of 3,4,5-methyl trihydroxybenzoate in toxicodenddron sylvestre leaves in prevention and control of plant bacterial diseases and oomycete diseases, wherein the 3,4,5-methyl trihydroxybenzoate can be artificially synthesized, and further can be separated and purified from a plurality of plants. According to the present invention, ether is adopted to extract antibacterial substances in toxicodenddron sylvestre leaf dry powder, a silica gel column chromatography method is adopted to separate and purify the 3,4,5-methyl trihydroxybenzoate, a production cost is low, and a production process is simple. The 3,4,5-methyl trihydroxybenzoate has a wide bacterial inhibition spectrum, and plant diseases can be prevented and controlled by applying toxicodenddron sylvestre plant residues or a 3,4,5-methyl trihydroxybenzoate agent. With the present invention, a new resource is provided for creation of new pesticides and research and development of bionic pesticides, and the toxicodenddron sylvestre plant resource is completely developed and utilized.

Owner:GUANGXI UNIV

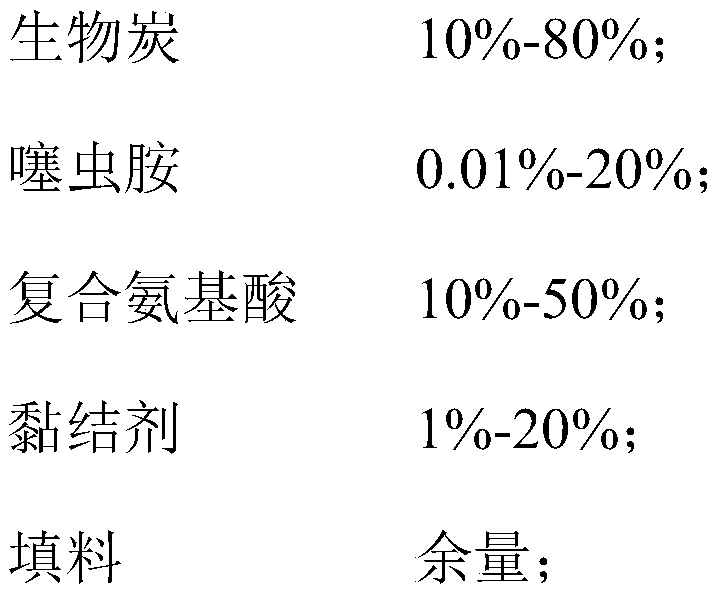

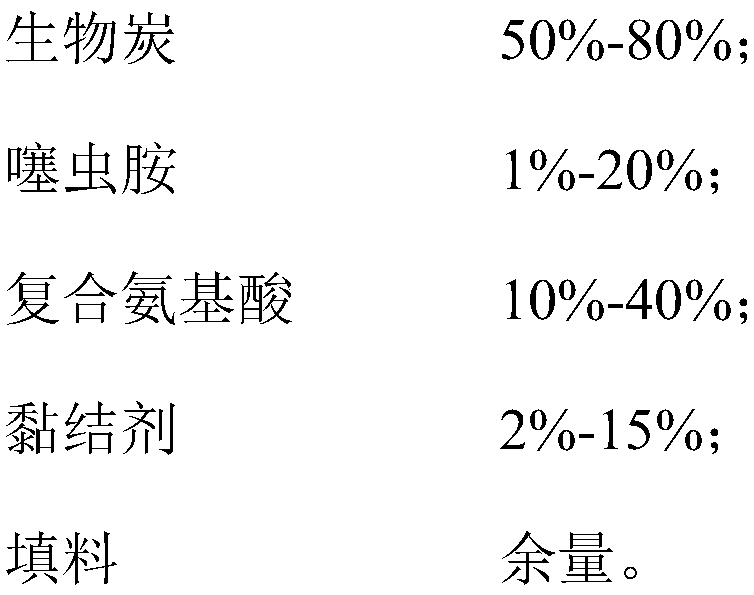

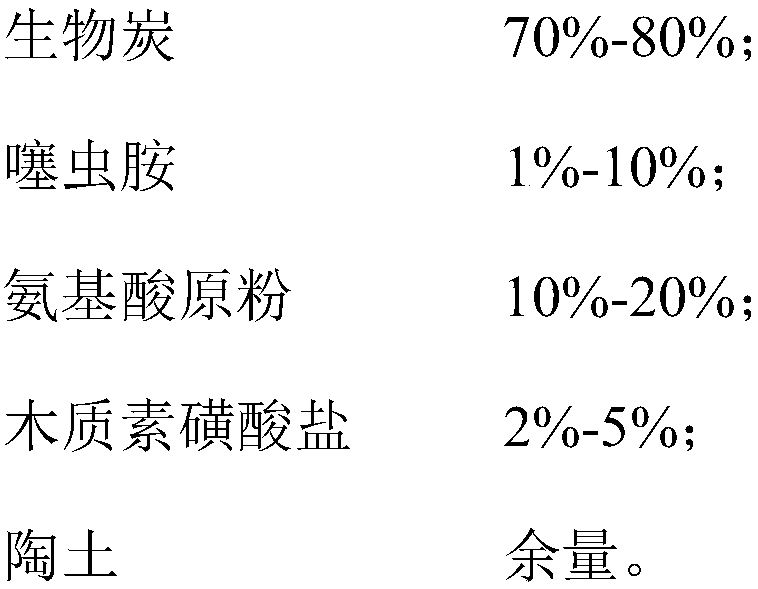

Biochar-based organic pesticide fertilizer containing thiamethanide and preparation method thereof

InactiveCN108863623AImprove adsorption capacityGood sustained release effectNitrogenous fertilisersFertilizer mixturesAdhesiveBiochar

The invention relates to a biochar-based organic pesticide fertilizer containing thiamethanide. The biochar-based organic pesticide fertilizer is prepared from the following raw materials in percentage by weight: 10% to 80% of biochar, 0.01% to 20% of thiamethanide, 10% to 30% of compound amino acid, 1% to 20% of adhesive, and the balance of filler. The biochar-based organic pesticide fertilizer has the advantages that the effects of fertilizer and pesticide are lasting, the safety in use is realized, the time is shortened, and the labor intensity is decreased.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

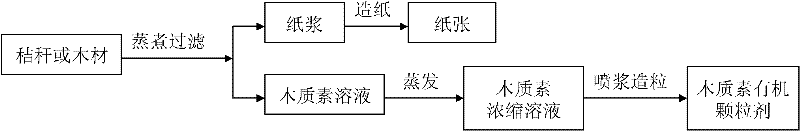

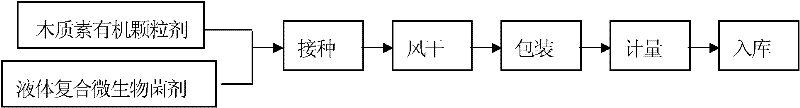

Method for producing bio-organic fertilizer by using lignin organic granules

InactiveCN102442847AFully reuseEliminate emission pollutionOrganic fertilisersFertilizer mixturesParticulatesSpray Granulation

The invention provides a method for producing a bio-organic fertilizer by using lignin organic granules. The method provided by the invention comprises steps of: preparing a liquid inoculant, preparing a lignin black liquor into an organic particulate agent by spraying granulation, and compounding the organic granules and the liquid composite inoculant, wherein the liquid composite inoculant which accounts for 0.5-1.5% of the weight of the finished product composite microbial fertilizer is added. The production of the bio-organic fertilizer can be completed by bacterial liquid permeation intoorganic particles and the technical requirement of the product can be reached without drying. According to the invention, routines are broken by creative introduction of the spraying granulation method into the biological fertilizer granulation technology. The production method of the particulate bio-organic fertilizer is divided into two steps of spraying granulation of the organic granules and organic granule wrapping or inoculant adsorption. In the meanwhile, a certain activity of the bio-organic fertilizer is maintained. According to the bio-organic fertilizer product, the breakthrough from a powder form to spray particles is realized, thus laying a foundation for the extensive popularization of the bio-organic fertilizer.

Owner:北京世纪大德环保科技有限公司

Production method of microbial inoculum

ActiveCN102174443AShort storage timePromote growthBacteriaMicroorganism based processesMicroorganismBacillus megaterium

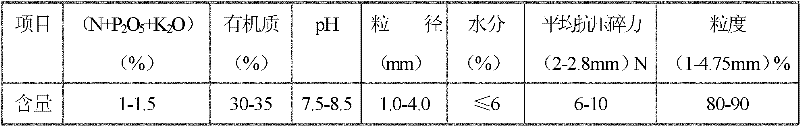

The invention provides a production method of microbial inoculum and the method contains the fermentation and adsorption of the strain. The method comprises the following steps: utilizing treated hydrolysis residue as a bacterium solution adsorption medium to absorb the fermented bacterium solution of one or more of Bacillus subtilis, Bacillus megaterium and Bacillus mucilaginous krassilm, wherein the weight ratio of the bacterium solution to the hydrolysis residue is 0.3:(2-4); and then mixing and crushing, thus obtaining the microbial inoculum. The invention provides a new powdery microbial inoculum adsorption carrier, and the carrier contains various nutrients for microbial growth, is favorable for microbial proliferation and growth and is environmentally-friendly and low in price.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Method for producing compound microbial fertilizer with microbial inoculum permeation and adsorption method

ActiveCN102442859AFlat surfaceHigh technical contentFertiliser formsFertilizer mixturesSpray GranulationBlack liquor

The invention provides a method for producing a compound microbial fertilizer with a microbial inoculum permeation and adsorption method. The method comprises the following steps of: preparing a liquid microbial inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum, whereinthe l inoculum; preparing a lignin black liquor into organic granules by performing spraying granulation; and compounding the organic granules with a liquid compound microbial inoculum is added in anamount of 0.5-1.5 percent by weight based on the total weight of a finished compound microbial fertilizer. Production of the compound microbial fertilizer is completed with a method for making a bacterial liquid permeate into the organic granules, and the technical requirements of a product can be met without drying. In the invention, a new path is opened, the convection is broken, a production method of a granular compound microbial fertilizer is partitioned into an organic granule granulating step and an organic granule coating step, a certain viable count in the compound microbial fertilizer is ensured simultaneously, breakthrough of a compound microbial fertilizer product from powdery granules to spraying granulation granules is realized, and foundations are laid for large-scale popularization of the compound microbial fertilizer.

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Organic fertilizer special for grapes and preparation method thereof

InactiveCN108892585APromote reproductionFacilitate optimal utilizationAlkali orthophosphate fertiliserExcrement fertilisersSludgeINCREASED EFFECT

The invention relates to the technical field of fertilizers and especially relates to an organic fertilizer special for grapes and a preparation method thereof. The organic fertilizer comprises the following raw materials: jute stems, pepper straws, wheat straws, potato dregs, kieselguhr, bone meal, duckweed, kalimeris herb, macro-elements, bentonite, bamboo charcoal, pond sludge, wormcast, micro-elements, compound probiotics and compound amino acids. According to the method provided by the invention, through the fermentation of the raw materials, the process of the plant straws converted intohumus is boosted, the physical and chemical properties of soil are obviously improved, and meanwhile, the soil structure is effectively improved, the use rate of a fertilizer is greatly increased, the fertilizing times can be reduced, the damage to soil caused by excessive fertilization is relieved and the yield-increasing effect is obvious.

Owner:松桃如阿雅观光农业产业开发有限公司

Production technology of trace element water-soluble fertilizer

InactiveCN105622242AThe effect of increasing production and income is obviousReduce fertilizer efficiencyFertilizer mixturesTrace elementManganese

The invention discloses a production technology of a trace element water-soluble fertilizer. The technology comprises the steps of chelating and uniform mixing. Copper, manganese, zinc and iron are chelated, and a surfactant, borax and ammonium molybdate are added to form a stable composite solution. The water-soluble fertilizer is sprayed on wheat, and has a substantial yield and income increase effect; and spraying of a foliar fertilizer has a law of the diminishing return, and the fertilizer efficiency of unit of a foliar fertilizer is reduced with the rising of the fertility of soil.

Owner:JIANGYIN LIANYE BIOTECHOLOGY

Sesbania seed treatment method

InactiveCN109220076AHard and solidEarly emergenceBiocideBio-organic fraction processingStress conditionsSeed treatment

The invention belongs to the field of agricultural cultivation and particularly relates to a sesbania seed treatment method. The method comprises the following steps of: (1) selecting and soaking plump and uniform sesbania seeds without diseases or pests into 3% hydrogen peroxide for treatment for 20min, (2) cleaning, airing and soaking the sesbania seeds in concentrated sulfuric acid for treatment for 20min, after soaking, immediately pouring off concentrated sulfuric acid, flushing the sesbania seeds under running water for 2h, and (3) taking out, cleaning and soaking the sesbania seeds in seed soaking liquid, stirring the sesbania seeds and the seed soaking liquid through a stirrer for 20min at a stirring rate of 30r / min, soaking the sesbania seeds for 1h after stirring, and horizontally laying the sesbania seeds on a cloth liner for airing. The sesbania seed treatment method can significantly increase a germination rate of the sesbania seeds under a salt stress condition.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

Special granular fertilizer suitable for saline-alkali land, and preparation method thereof

InactiveCN108911902APrevent deliquescenceImprove fertilizer efficiencySuperphosphatesExcrement fertilisersAlkali soilCrop growth

The invention discloses a special granular fertilizer suitable for saline-alkali land, and a preparation method thereof, wherein the special granular fertilizer is prepared sequentially from a core material layer, a sustained-release layer, a soil action layer and a coating layer according to a certain ratio from inside to outside, and the granular fertilizer having the four-layer coated structureis obtained through multiple granulation. According to the present invention, the coating layer in the granular fertilizer can prevent the granular fertilizer from deliquescene before the applicationinto the soil so as to maintain the high fertilizer efficiency; after the special granular fertilizer is applied into the saline-alkali land soil, the added coating layer is dissolved under the action of the water of the soil layer, and the fertilizer in the soil action layer is gradually released into the peripheral saline-alkali land, such that the saline-alkali land soil is subjected to targeted improvement to the maximum extent; when the saline-alkali land is repaired to a suitable planting state, the core material layer mainly for nourishing crops is slowly released under the action of the sustained-release layer, such that the fertilizer in the core material layer is not affected by the saline-alkali land soil so as to act on the crop growth to the maximum extent; and various layerrespectively provide the effects in the targeted manner so as to achieve the optimal effect of the granular fertilizer.

Owner:贺康

Ecological organic potassium-selenium fertilizer

The invention relates to an organic fertilizer, in particular to an ecological organic potassium-selenium fertilizer. The fertilizer is characterized by being prepared from the following raw materials in parts by weight: 30-80 parts of 70% humic acid, 200-800 parts of 95% potassium sulfate, 5-15 parts of zinc sulfate, 20-80 parts of 20% amino acid, 200-800 parts of brown sugar and 500-1500 parts of edible acetic acid. By adopting the potassium-selenium fertilizer, the soil can be improved and soil compaction caused by the use of fertilizer can be improved; the water conservation, nutrient conservation and nutrient supply capabilities of soil can be increased. The fertilizer also has pest resistance, drought resistance and cold resistance; and the fertilizer has obvious effect of increasing crop quality, soil fertility and fertilizer efficiency.

Owner:西安谦坤商务咨询管理有限公司

Granular fertilizer special for environment-friendly saline-alkali soil and preparation method thereof

InactiveCN108947707APrevent deliquescenceImprove fertilizer efficiencySuperphosphatesAmmonium salt fertilisersAlkali soilCrop growth

The invention discloses a granular fertilizer special for environment-friendly saline-alkali soil and a preparation method thereof. The granular fertilizer is prepared from a core layer, a slow release layer, a soil acting layer and an enveloping layer at a certain ratio from inner to outer. The granular fertilizer with a four-layer cladding structure is acquired through repeated pelletizing. Before the granular fertilizer disclosed by the invention is applied to soil, the enveloping layer in the granular fertilizer is capable of preventing the granular fertilizer from deliquescing and keepinghigher fertilizer efficiency; after the granular fertilizer is applied to the saline-alkali soil, the enveloping layer is dissolved under the action of water in the soil, and then the fertilizer in the soil acting layer is gradually released into the surrounding saline-alkali soil and the saline-alkali soil can be specifically and extremely improved; when the saline-alkali soil is recovered to astate suitable for planting, the core layer mainly used for nourishing crops starts to slowly release under the action of the slow release layer, the fertilizer in the core layer is not influenced bythe saline-alkali soil and is extremely used for promoting the crop growth; all the layers have a definite purpose and perform own functions, so that the granular fertilizer can be fully utilized.

Owner:贺康

Fixing agent and method for controlling nicotine loss during tobacco waste composting

InactiveCN104478619ASettle the lossImprove insecticidal effectBio-organic fraction processingExcrement fertilisersCompostLivestock manure

Owner:ANHUI SCI & TECH UNIV

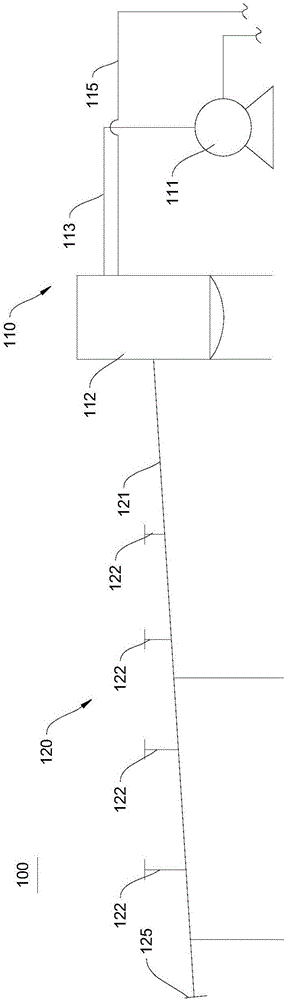

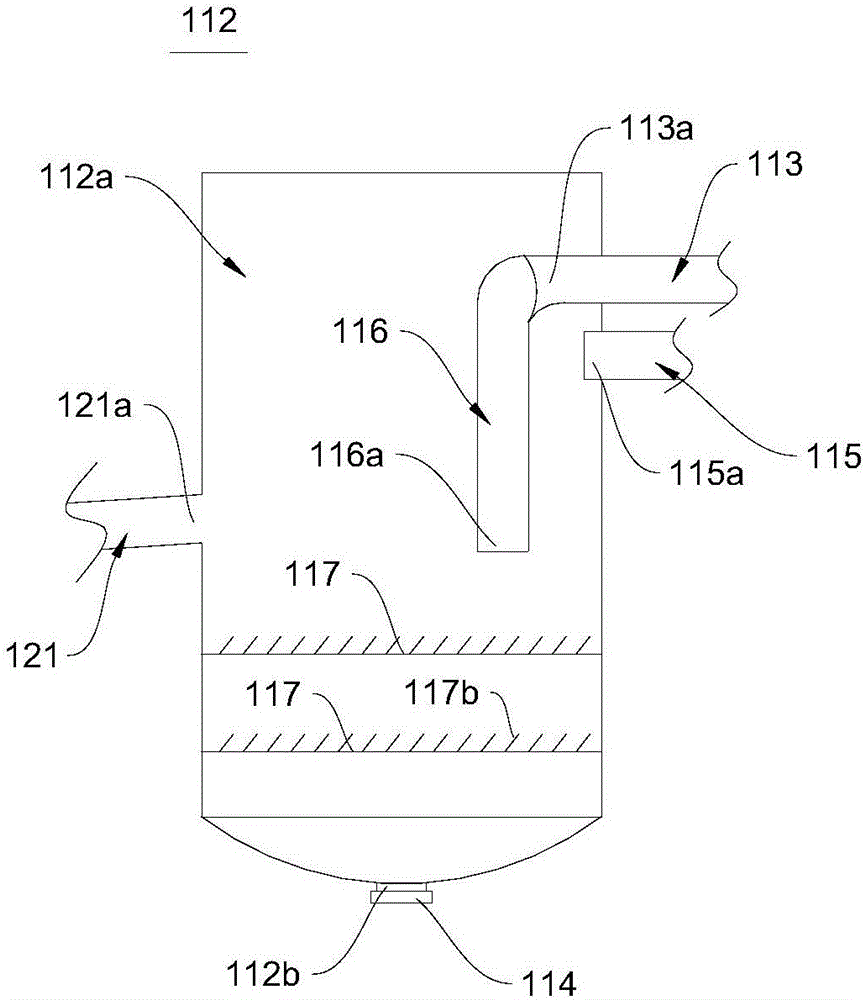

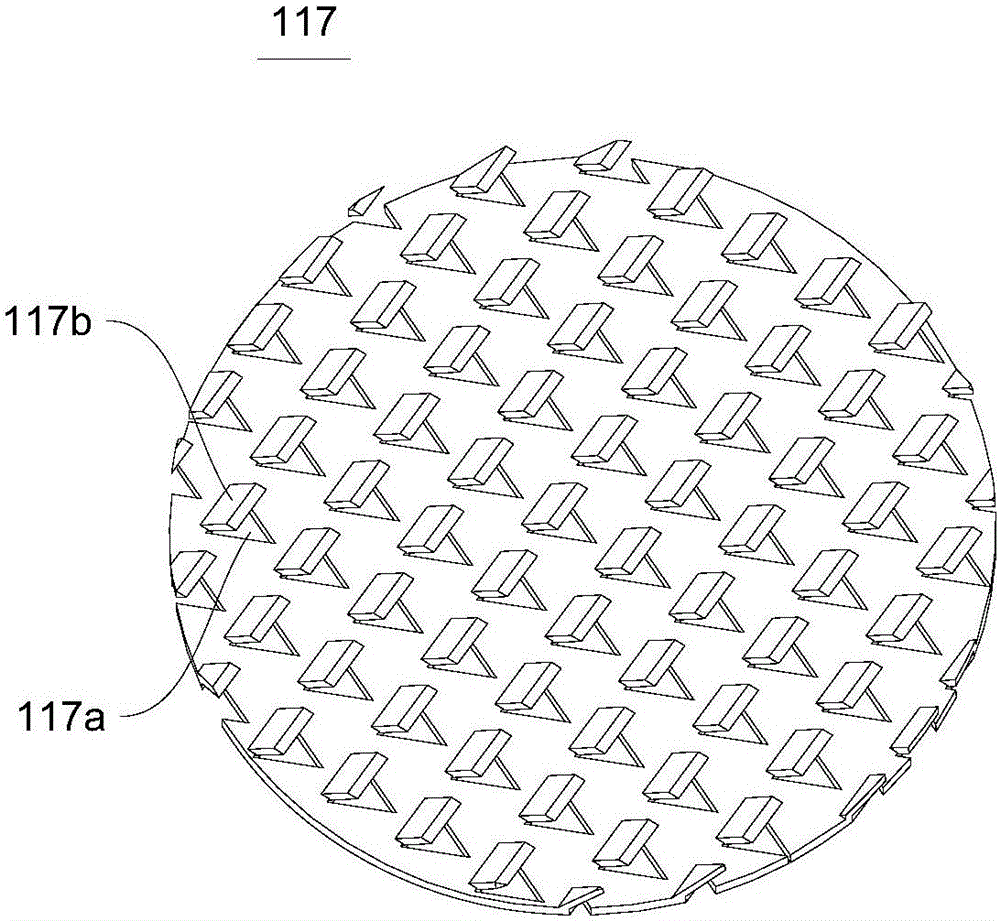

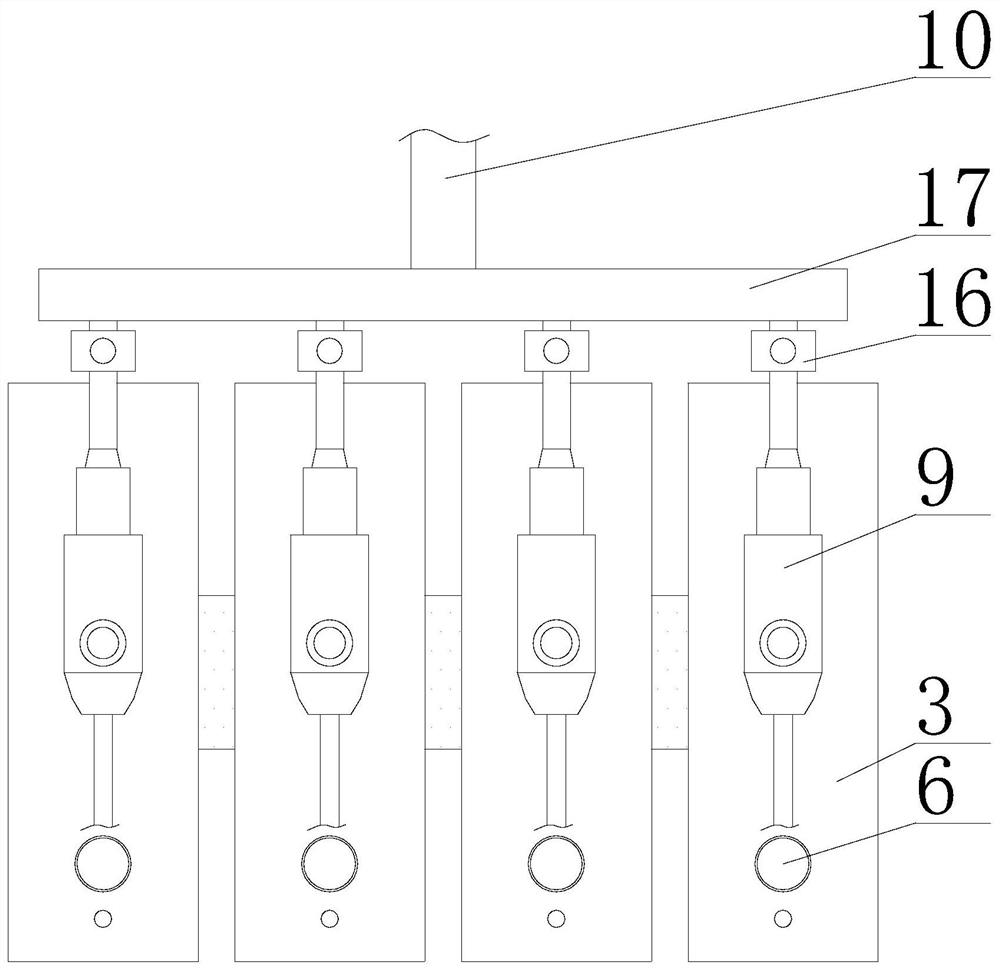

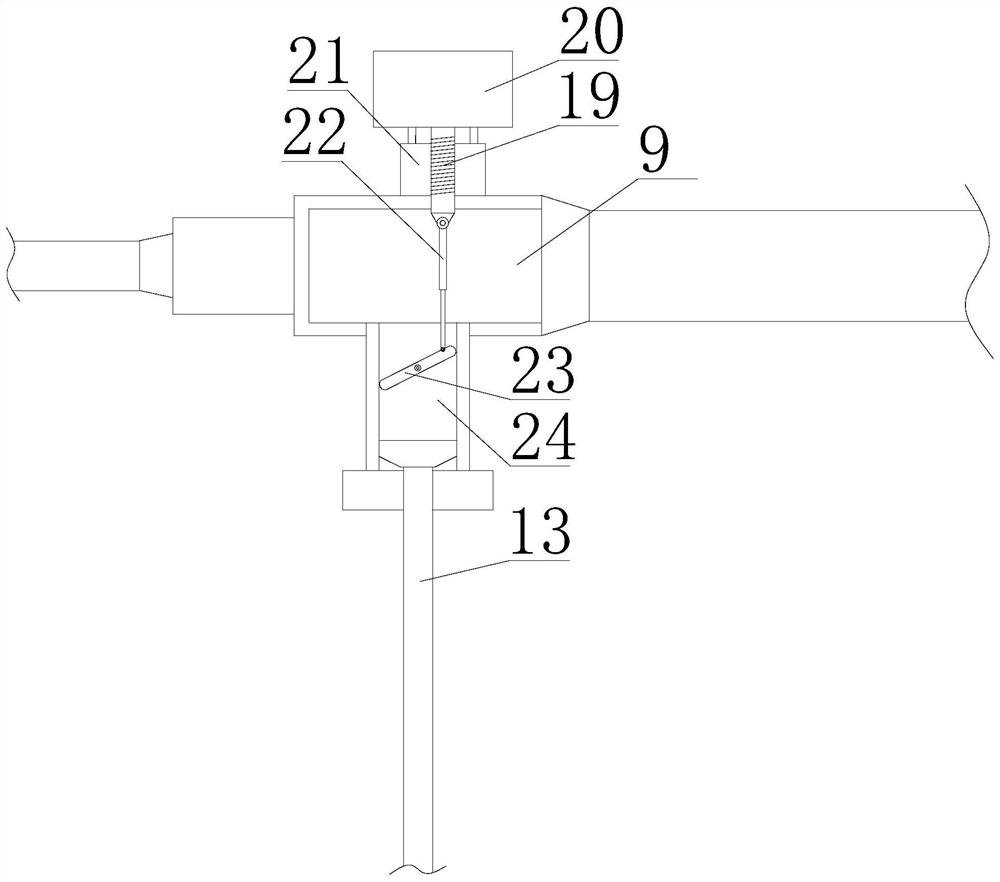

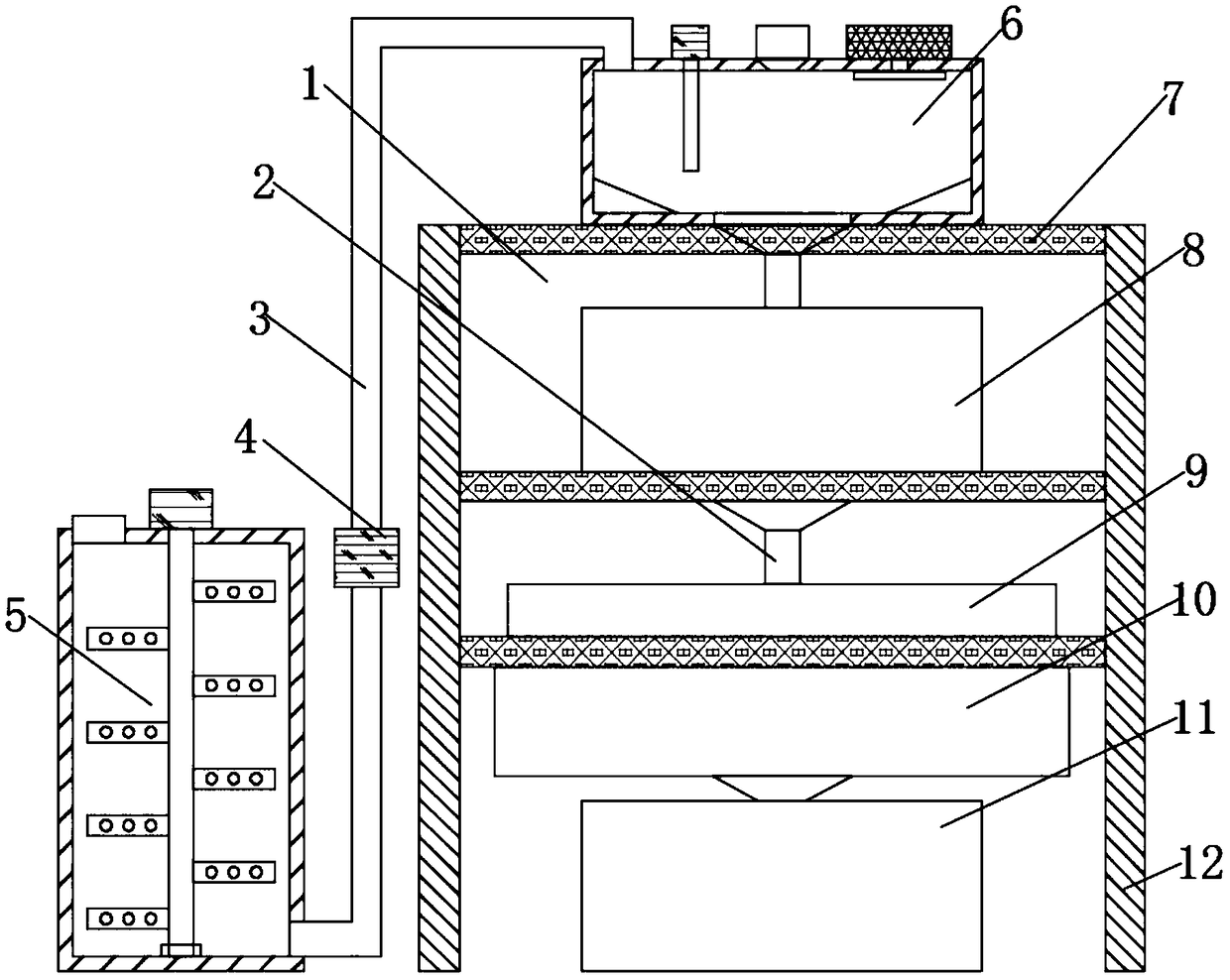

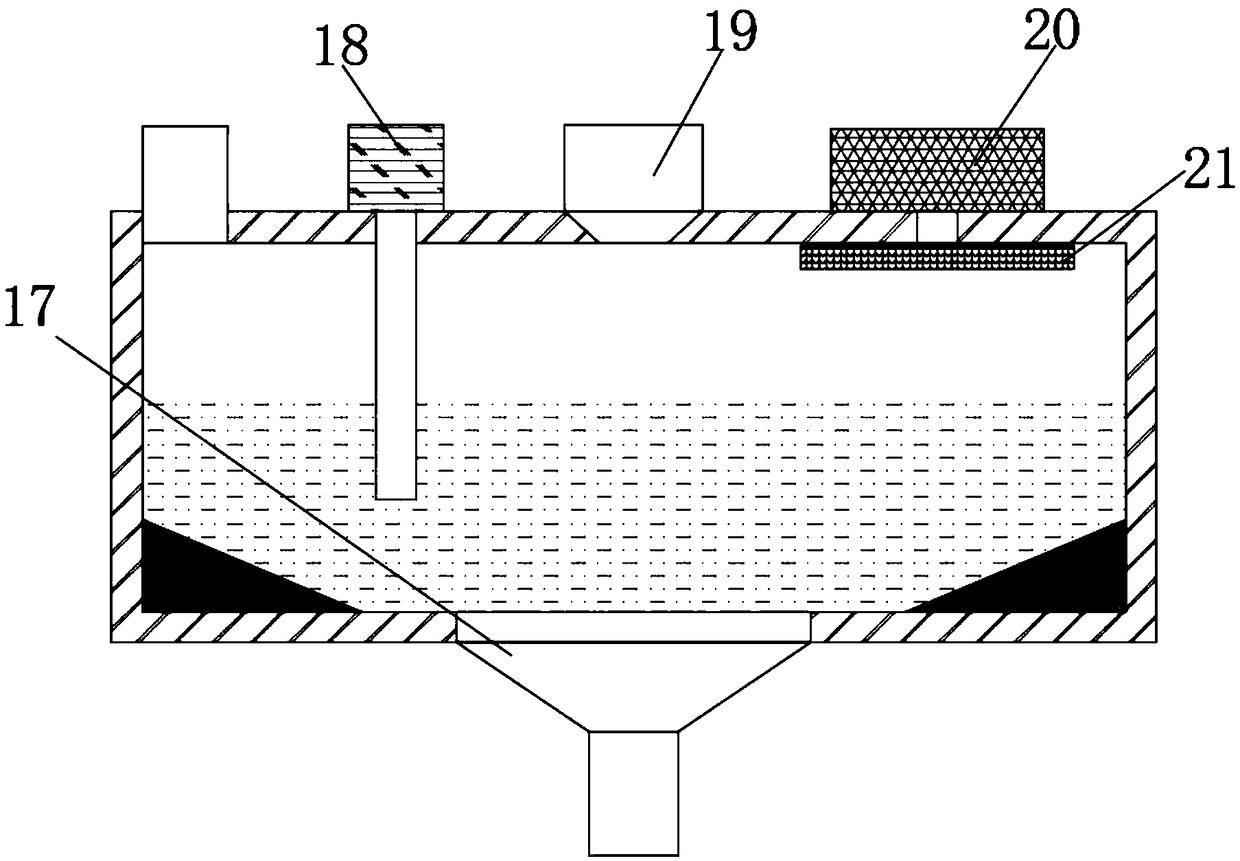

Irrigation water pretreatment system and farm irrigation system

PendingCN106745611AReduce dosageMaximize fertilizer efficiencyTransportation and packagingRotary stirring mixersImpellerEngineering

The invention relates to an irrigation water pretreatment system and a farm irrigation system, which relate to the technical field of agriculture irrigation. The irrigation water pretreatment system comprises a primary precipitation tank, a mixing and adjusting tank, a detection system and a water lifting and distributing system. The primary precipitation tank is communicated with the mixing and adjusting tank, and the detection system is arranged in the mixing and adjusting tank. The water lifting and distributing system comprises a water lifting and allocating apparatus and a water distribution pipe, the water lifting and allocating apparatus comprises a lifting pump and a water allocator, an inlet of the lifting pump is arranged in the mixing and adjusting tank, an outlet of the lifting pump is communicated with the water allocator, and an inlet of the water distribution pipe is communicated with the water allocator. The water allocator is provided with a stirring assembly, and the stirring assembly comprises a stirring rod, a stirring impeller and a power apparatus. One end of the stirring rod is accommodated in the water allocator, the other end penetrates through the water allocator and is connected with a power output portion of the power apparatus, and the stirring impeller is engaged with the stirring rod by virtue of a bevel gear. The farm irrigation system comprises the irrigation water pretreatment system. By adopting the irrigation water pretreatment system and the farm irrigation system, cultivation biogass slurry can satisfy the fertilizing standard, zero emission is realized, and the fertilizer efficiency of the cultivation biogass slurry can be maximized.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

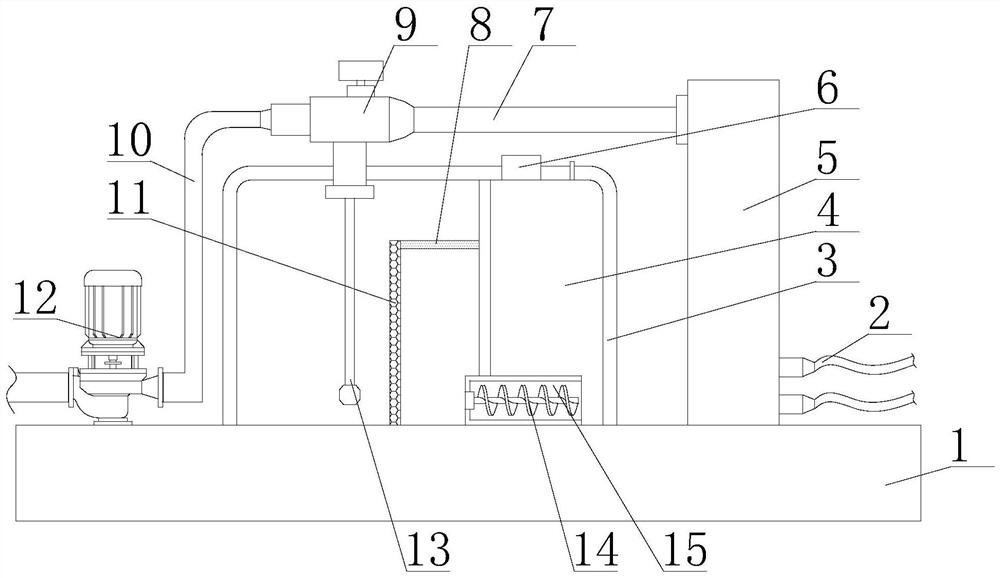

Automated water-fertilizer integrated machine for intelligent planting

ActiveCN111837567AMixed real timeDissolving real-time fastManure treatmentClimate change adaptationFertilizerAgricultural engineering

The invention relates to the technical field of agricultural equipment and discloses an automated water-fertilizer integrated machine for intelligent planting. The automated water-fertilizer integrated machine comprises a base, wherein a water injection pump is fixedly mounted at the top of the base, an output end of the water injection pump fixedly communicates with a water outlet pipe, a fertilizer storage chamber which is located at the right side of the water injection pump is fixedly mounted at the top of the base, a water and fertilizer mixing device is fixedly mounted at the top of thefertilizer storage chamber, and the bottom of the water and fertilizer mixing device extends inside the fertilizer storage chamber and is fixedly connected with a charging pipe. According to the automated water-fertilizer integrated machine for intelligent planting, the water and fertilizer mixing device is arranged above the fertilizer storage chamber, so that after clean water is introduced intothe water and fertilizer mixing device, internal pressure of the water and fertilizer mixing device is lowered by using a Bernoulli principle, and thus, a liquid fertilizer, located at the left sideof a middle partition plate, of the fertilizer storage chamber is automatically sucked into the water and fertilizer mixing device by a communicating seat through the charging pipe and is subjected toreal-time water and fertilizer mixing.

Owner:滁州联润生态农业发展有限公司

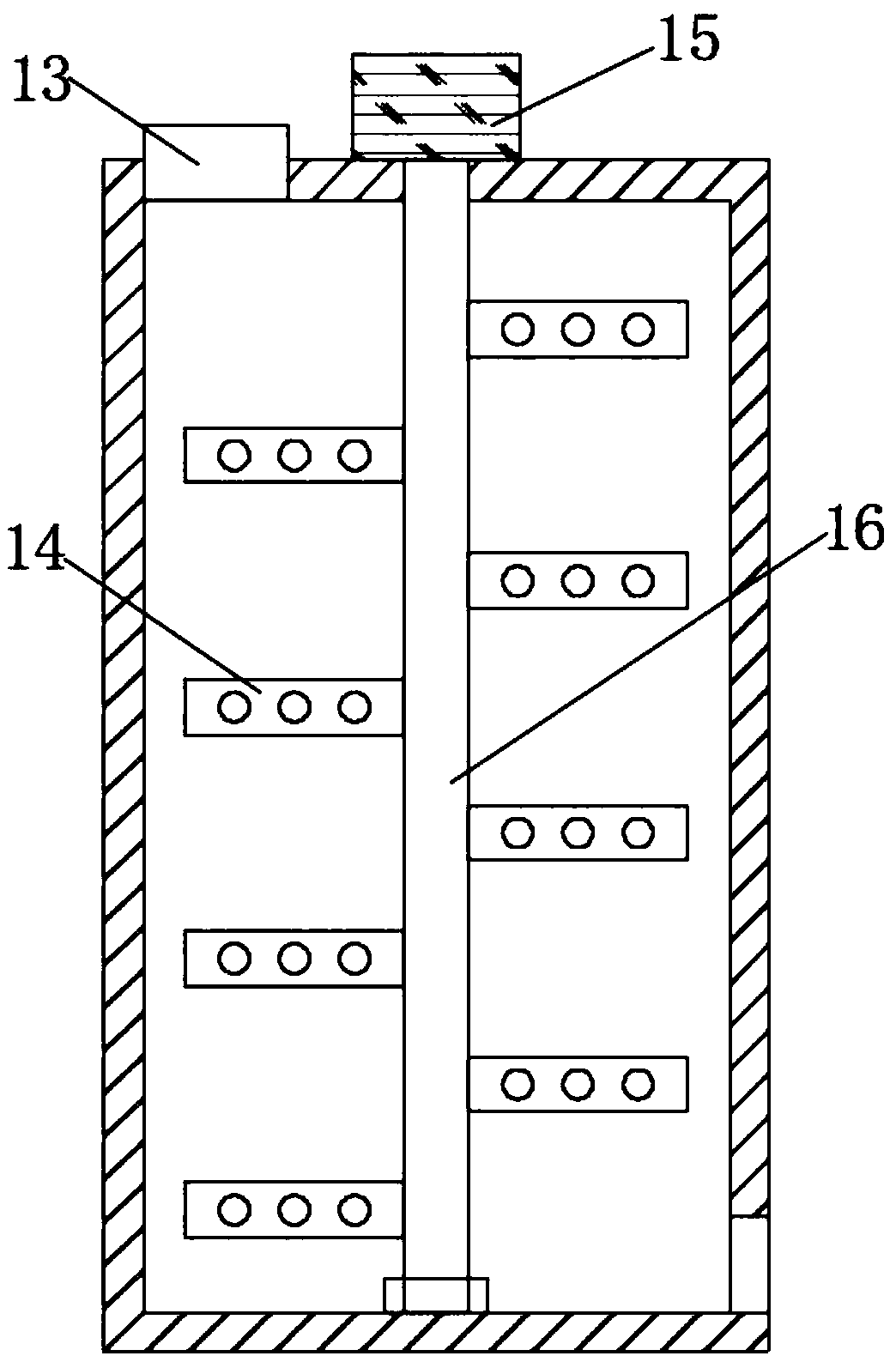

Processing equipment for biomass charcoal chicken manure fertilizer

InactiveCN108840723AThorough processingIncrease profitClimate change adaptationExcrement fertilisersAgricultural engineeringAmmonia

The invention discloses processing equipment for biomass charcoal chicken manure fertilizer. The processing equipment is characterized in that a stirring box is arranged on one side of a main processing equipment body, a feeding port and a motor are arranged at the top of the stirring box, and a stirring shaft is mounted at the bottom of the motor; an ammonia pump can provide a good anaerobic environment for inside of a fermentation box, meanwhile, biomass charcoal in a biomass charcoal bin is added to a material, then the blended material enters a drying chamber and is subjected to preliminary drying by a drying filter screen, the dried fertilizer enters a granulating mechanism for processing and granulation, and the granulated fertilizer can enter a collecting box at the bottom along a discharging hopper. The processing equipment for the chicken manure fertilizer is relatively thorough in chicken manure processing and relatively high in efficiency and can increase the utilization rate of chicken manure to a great degree, by means of repeated fermentation processing, part of internal components can be transformed into organic gas for use, meanwhile, fertilizer efficiency of the chicken manure can be reduced to a certain degree, so that crop yield reduction due to crop seedling burn by the chicken manure fertilizer is avoided, and great convenience is brought to production of people.

Owner:颜伟锦

Special fertilizer for myrica rubra dongkui

InactiveCN104945116AStrong antibioticImprove disease resistanceFertilizer mixturesPhosphatePotassium

The invention discloses a special fertilizer for myrica rubra dongkui, and relates to the technical field of fertilizers. The special fertilizer comprises an organic matter, an inorganic matter, a microorganism, a microelement and a biological growth regulator, and is characterized in that the mass percent of the organic matter is greater than or equal to 20%; the inorganic matter comprises nitrogen, phosphorus and potassium; the mass percent of the inorganic matter is greater than or equal to 25%; the mass percent of the microelement is greater than or equal to 3%; the mass percent of the microorganism is 2-3%; the microorganism comprises thermophilic sporotrichum, dinitrogenase, phosphate-solubilizing enzyme and formate-solubilizing enzyme at a ratio of 1:1.2:1:1.5; and the mass percent of the biological growth regulator is 0.1-0.3%. The special fertilizer is complete in nutrition and high in fertilizer supply capability, and can improve the soil quality, so that the myrica rubra dongkui is high in stress resistance and high in yield.

Owner:LANGXI LINGLONG MOUNTAIN VILLA

Granular Ca-Mg-P fertilizer

InactiveCN1451638AImprove fertilizer efficiencyReduce fertilizer efficiencyFertiliser formsFertilizer mixturesActive componentMagnesium sulphate heptahydrate

A granular CaMgP fertilizer is prepared from ordinary CaMgP fertilizer through mixing it with the solution of magnesium sulfate and granulating. Its advantages are easy dissolving in water, easily releasing its active components, easy being assimilated, and durable fertility.

Owner:黄雄强

Cultivation method of cattle green fodder

InactiveCN106912292ALow costFull of nutritionPlant cultivationCultivating equipmentsFertilizerNutrient

The invention discloses a cultivation method of cattle green fodder. The cultivation method comprises the following steps: 1, mounting cultivation equipment; 2, cultivating the cattle green fodder; 3, carrying out water and fertilizer management; 4, carrying out temperature management; 5, carrying out illumination management; 6, carrying out pest and disease damage management; 7, carrying out gas management. The cultivation method of the cattle green fodder, disclosed by the invention, can be used for producing in a whole year; the quantity of seeds can be determined according to a cattle feeding scale and the use amount of cattle per day; phenomena that the cattle green fodder is too much to be wasted and is too less to be not sufficient can be completely avoided and the yield of a unit area is high; 20 tons or more of fresh cattle green fodder can be produced through three-dimensional cultivation per square meter. The cattle green fodder produced by the method has abundant nutrient value and the content of crude proteins, vitamins and microelements is high; the cattle green fodder is palatable and has no pollution; the intake amount of the cattle can be increased and fattening cattle can grow for about 2kg per day after the cattle green fodder is used for a long period, so that the cattle green fodder is optimal green fodder for large-scale cultivation and production of green beef.

Owner:莫力达瓦达斡尔族自治旗兴军农业生态发展有限公司

Method for preparing high-tower nitro type seaweed composite fertilizer

PendingCN110396012AHigh Algae ActivesImprove high temperature resistanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDigestion

A method for preparing a high-tower nitro type seaweed composite fertilizer is disclosed. The method includes S1) chopping dry seaweed into small segments; S2) putting water into a digestion tank, stirring, adding potassium carbonate and then degrading the small seaweed segments; S3) sealing the digestion tank for digestion and degradation to obtain a liquid mixture, and performing centrifugationwhen the temperature of the liquid mixture in the tank decreases to 60 DEG C to obtain a centrifugate; S4) adding potassium humate into the centrifugate; S5) concentrating the centrifugate; S6) spray-drying the centrifugate to obtain a seaweed extract; S7) adding monoammonium phosphate, ammonium sulfate, potassium sulfate, potassium chloride and the seaweed extract to a high-tower ammonium nitratetank containing an ammonium nitrate solution, then mixing and grinding the materials, feeding the mixture to a high-tower granulator for granulation, and then performing sieving, cooling and coatingto obtain the composite fertilizer. The composite fertilizer produced by the method has more seaweed active substances, can achieve root promoting, seedling strengthening and shoot strengthening, andhas better flower and fruit protecting and stress resistance effects.

Owner:HUBEI NEWYANGFENG FERTILIZER STOCK

Method for producing compound microbial fertilizer by microbial inoculum packing method

ActiveCN102040434BReduce manufacturing costSolve the production processFertilizer mixturesAgricultural engineeringAbamectin

Owner:SHANGHAI NUOTONG INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com