Special Ginseng composite mixed fertilizer

A technology of compound fertilizer and ginseng, which is applied in the directions of organic fertilizer, fertilizer mixture, application, etc., can solve the problems of restricting the promotion and application of biological fertilizer, increasing the cost of biological fertilizer, losing the activity of biological fertilizer, etc., so as to improve the quality of ginseng and resist diseases and insect pests. Capacity, low cost, effect of increasing organic matter and agglomerate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

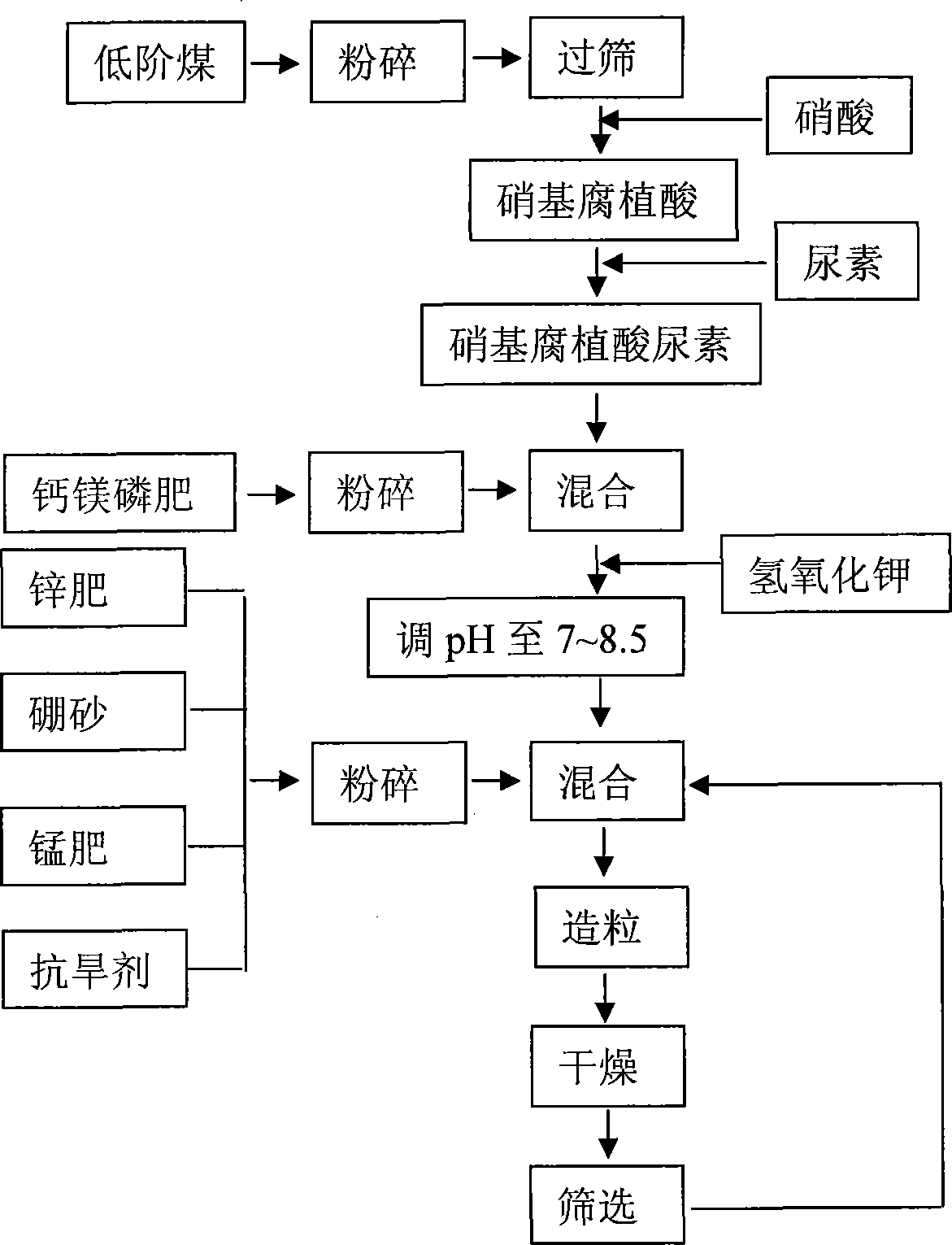

Image

Examples

Embodiment 1

[0024] Weigh 1000g of air-dried peat with a humic acid content of more than 20% and a particle size of less than 2mm, add 1500ml of 30% nitric acid, stir evenly, heat to 50°C, react for 25min, and filter to obtain the crude nitrohumic acid filtrate. Acid: urea=1:1 weight ratio, add urea to the filtrate, heat to 70°C, and react for 1.5 hours to obtain nitrohumic acid urea complex. According to the following mass ratio: complex 100g, add calcium magnesium phosphate fertilizer 8g, adjust pH to 7 with potassium hydroxide, heat to 80°C again, then add borax 0.01g, zinc sulfate 0.01g, manganese sulfate 0.01g, drought resistance agent The biodegradable superabsorbent resin is crushed to 1~2mm (0.05g), mixed evenly, and granulated for 3 minutes. Dry at 70°C for 20min.

Embodiment 2

[0026] Weigh 1000g of air-dried lignite with a humic acid content of more than 20% and a particle size of less than 2mm, add 2000ml of 30% nitric acid, stir evenly, heat to 60°C, react for 30min, and filter to obtain the crude nitro humic acid filtrate. Humic acid: urea = 1:1 weight ratio, add urea to the filtrate, heat to 80°C, and react for 2 hours to prepare nitro humic acid urea complex. According to the following ratio: complex 100g, add calcium magnesium phosphate fertilizer 8g, adjust pH to 8.0 with potassium hydroxide, heat to 80°C, then add borax 0.03g, zinc sulfate 0.015g, manganese sulfate 0.015g, drought resistance agent 0.07g, Mix well and granulate for 7 minutes. Dry at 110°C for 25min.

Embodiment 3

[0028] Weigh 1000g of air-dried weathered coal with a humic acid content of more than 20% and a particle size of less than 2mm, add 3000ml of 30% nitric acid, stir evenly, heat to 70°C, react for 30min, and filter to obtain the crude nitrohumic acid filtrate. Base humic acid: urea=1:2 weight ratio, add urea to the filtrate, heat to 85 ° C, react for 2.5 hours, and prepare nitro humic acid urea complex. According to the following ratio: 100g of complex, add 10g of calcium magnesium phosphate fertilizer, adjust pH to 8.5 with potassium hydroxide, heat to 85°C, then add 0.02g of borax, 0.05g of zinc sulfate, 0.02g of manganese sulfate, 0.1g of drought resistance agent, Mix well, send to granulator, granulate for 10 minutes. Dry at 120°C for 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com