Production method of biological organic fertilizer containing Avermectins

A bio-organic fertilizer and abamectin technology, applied in the direction of organic fertilizers, can solve problems such as time-consuming, affecting fertilizer efficiency, and difficult to dissolve, and achieve the effects of increasing technical content, improving application effects, and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

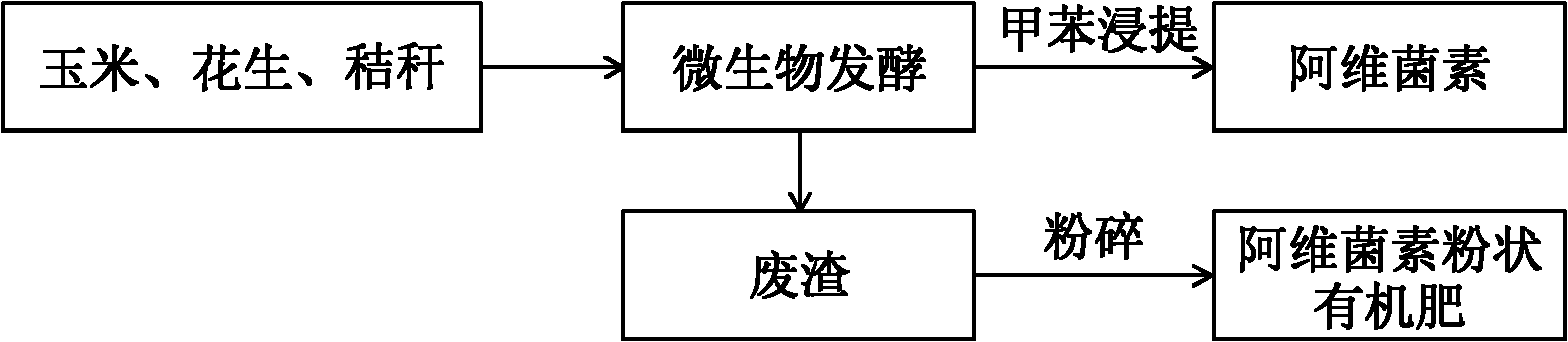

Method used

Image

Examples

Embodiment 1

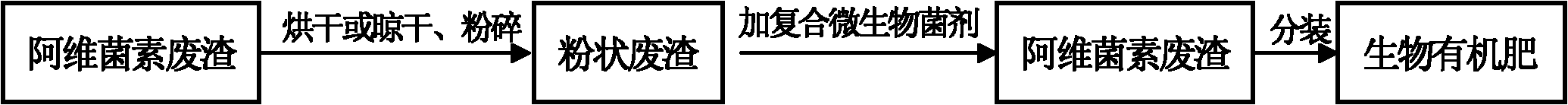

[0038] 1. Waste residue treatment: dry or air-dry the abamectin waste residue to make the moisture ≤ 30%, and then crush the waste residue to 60-80 mesh; the basic properties of the waste residue are shown in Table 4, and the heavy metal content is far lower than that of bio-organic fertilizers The industry standard (see Table 1), not measured.

[0039] Table 4: Basic properties of abamectin waste residue after treatment

[0040]

[0041] 2. Preparation of compound microbial bacterial agent: Bacillus subtilis, Bacillus megaterium and Bacillus mucilaginosus are produced by separate fermentation, and the fermented bacterial liquid is pressed with 80 mesh rice husk powder Bacteria liquid: rice husk powder = 1:3 ratio adsorption, the three adsorbed single bacterial agents were mixed and pulverized to 60 mesh according to the ratio of 0.7:0.8:1.5, so that the total number of viable bacteria of the three strains after mixing reached 7.6× 10 8 more than one per gram, the water c...

Embodiment 2

[0046] Except following process, other is as embodiment 1.

[0047] Bacillus subtilis (Bacillus subtilis), Bacillus megaterium (Bacillus megaterium) and Bacillus mucilginosus (Bacillus mucilginosus) are separately fermented and produced, and the fermented bacterial liquid is pressed with 100 mesh rice husk powder according to bacterial liquid: rice husk powder=1 : 3 ratio adsorption, the three adsorbed single bacterial agents were mixed and pulverized to 70 mesh according to the ratio of 1:0.8:2.5, so that the total number of viable bacteria of the three strains after mixing reached 7.2×10 8 more than one per gram, the water content is kept at 25-30%.

[0048] Ingredients: 220kg of powdery waste residue, 10kg of compound microbial agent, 8kg of magnesium sulfate, 6kg of zinc sulfate, and 6kg of ferrous sulfate.

Embodiment 3

[0050] Except following process, other is as embodiment 1.

[0051] Bacillus subtilis (Bacillus subtilis), Bacillus megaterium (Bacillus megaterium) and Bacillus mucilginosus (Bacillus mucilginosus) are separately fermented and produced, and the fermented bacterial liquid is pressed with 120 mesh rice husk powder according to bacterial liquid: rice husk powder=1 : 3 ratio adsorption, the three adsorbed single bacterial agents were mixed and pulverized to 80 mesh according to the ratio of 0.5: 0.6: 0.75, so that the total number of viable bacteria of the three strains after mixing reached 7.5×10 8 more than one per gram, the water content is kept at 25-30%.

[0052] Ingredients: 217.5kg of powdery slag, 15kg of compound microbial agent, 6kg of magnesium sulfate, 5.5kg of zinc sulfate, 3kg of borax, and 3kg of ferrous sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com