Sodium potassium lithium niobate-bismuth potassium sodium zirconate-bismuth scandate ternary leadless piezoelectric ceramic

A technology of bismuth scandate ternary system and bismuth sodium potassium zirconate is applied in the preparation of lead-free piezoelectric ceramics, potassium sodium lithium niobate-bismuth sodium potassium zirconate-bismuth scandate ternary system lead-free piezoelectric ceramics It can solve problems such as ensuring a higher Curie temperature, and achieve the effect of widening the temperature range, easy implementation, and widening the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

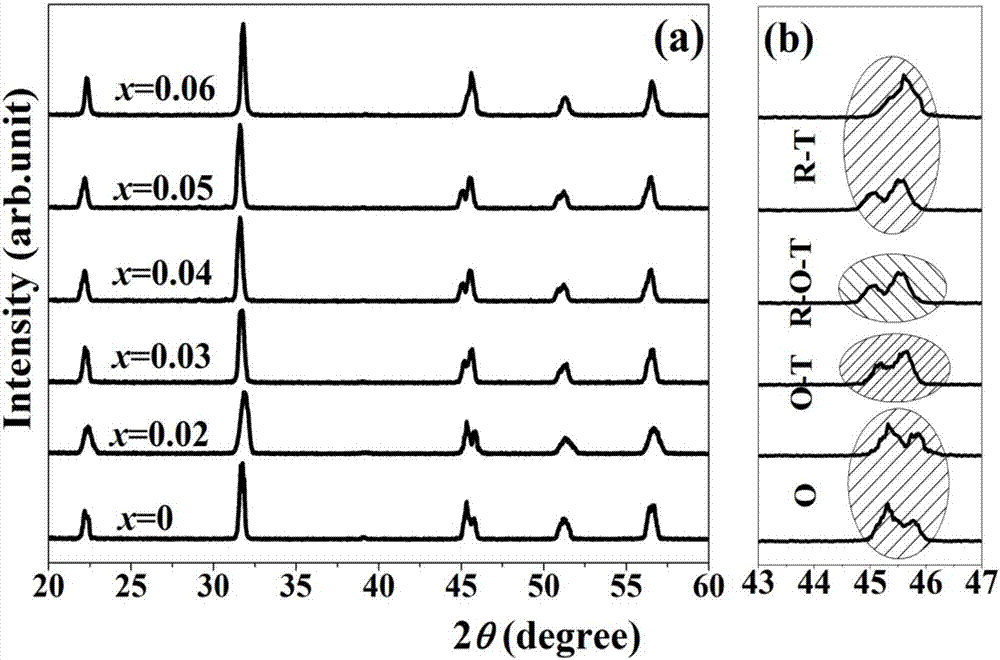

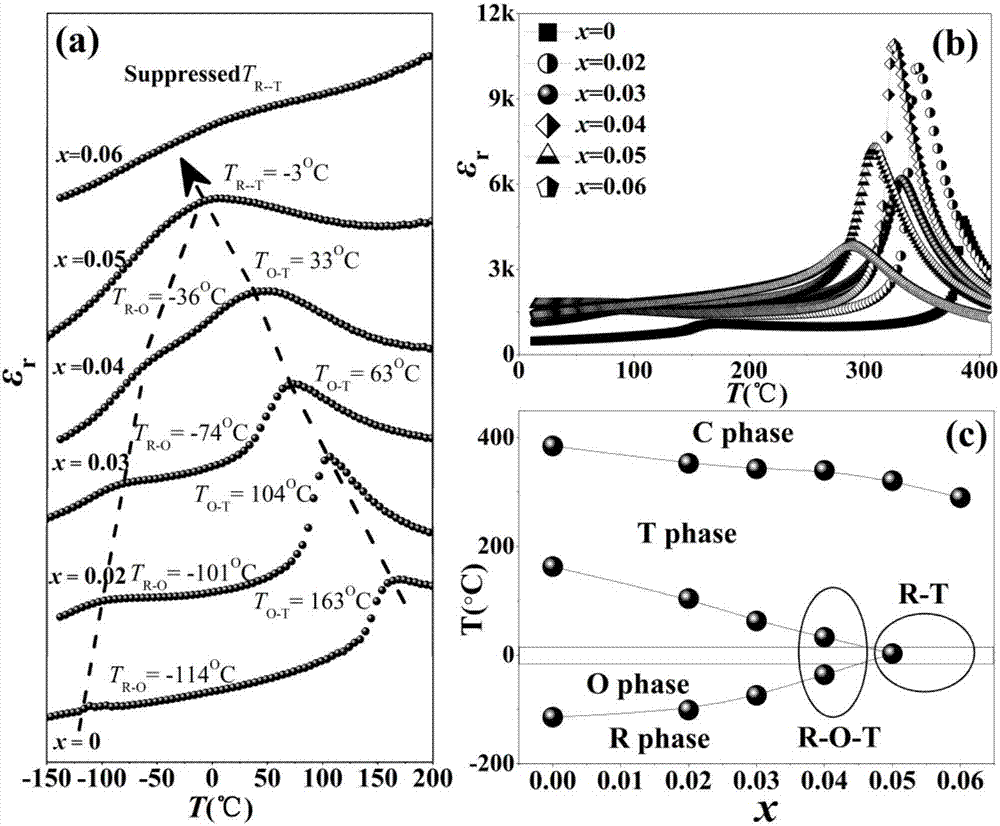

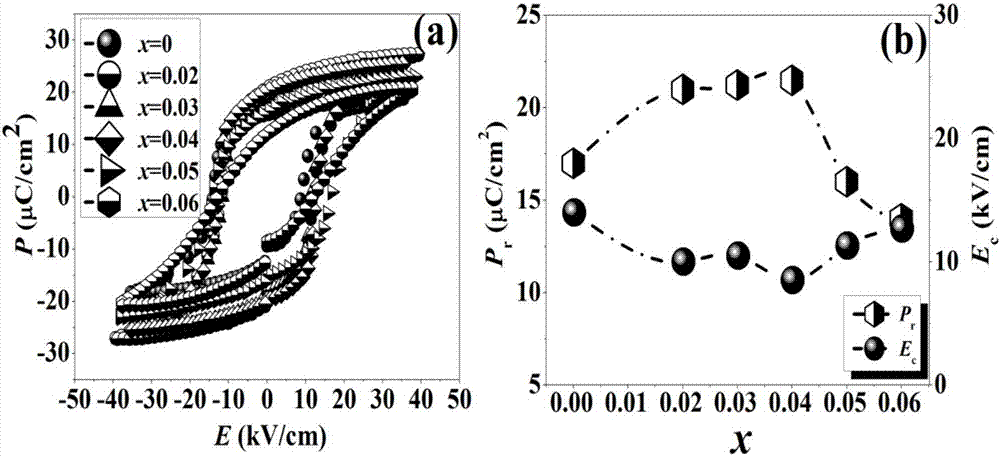

[0036] Potassium sodium lithium niobate-bismuth sodium potassium zirconate-bismuth scandate ternary system lead-free piezoelectric ceramics, the general structure of which is: (0.995-x)(K 0.5 Na 0.5 ) 0.97 Li 0.03 NbO 3 -xBi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 -0.005BiScO 3 , where x=0.00 (sample 1).

[0037] The preparation method of the above-mentioned lithium potassium niobate-sodium bismuth zirconate-bismuth scandate ternary system lead-free piezoelectric ceramic is as follows:

[0038] (1) Ingredients:

[0039] with K 2CO 3 、Na 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 、Sc 2 o 3 As a raw material, according to the chemical formula 0.995 (K 0.5 Na 0.5 ) 0.97 Li 0.03 NbO 3 -0.005BiScO 3 To weigh ingredients;

[0040] (2) Preparation:

[0041] The prepared raw materials are mixed with absolute ethanol as the ball milling medium, and the rolling ball milling method is used to mix them evenly and then dry to obtain powder; heat the obtained powder at 700...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is: in this embodiment, x=0.02 (sample 2), and the piezoelectric ceramic general formula is 0.975 (K 0.5 Na 0.5 ) 0.97 Li 0.03 NbO 3 -0.02Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 -0.005BiScO 3 .

[0044] In the preparation method of the present embodiment: with K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 、Sc 2 o 3 , ZrO 2 As a raw material, the ceramic green sheet after debinding is heat-preserved and sintered at 1080° C. for 2 to 5 hours to obtain ceramics.

Embodiment 3

[0046] The difference between this embodiment and embodiment 2 is that in this embodiment, x=0.03 (sample 3), and the general formula of the piezoelectric ceramic is 0.965 (K 0.5 Na 0.5 ) 0.97 Li 0.03 NbO 3 -0.03Bi 0.5 (Na 0.8 K 0.2 ) 0.5 ZrO 3 -0.005BiScO 3 .

[0047] In the preparation method of this embodiment: the ceramic green sheet after debinding is heat-preserved and sintered at 1090° C. for 2-5 hours to obtain ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com