Efficient composite desulfurization agent, preparation method and applications thereof

A desulfurizer and high-efficiency technology, which is applied in the hot metal pretreatment process and steelmaking process, can solve the problems of large temperature loss of molten iron, unfavorable desulfurization, and increased oxygen potential, so as to reduce the consumption of desulfurizer, improve the properties of molten iron slag, and reduce the temperature loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

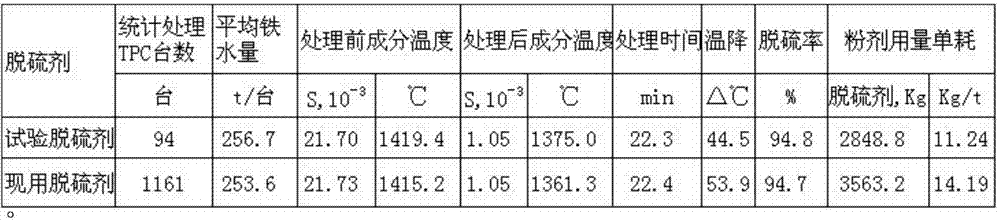

[0041] At present, this high-efficiency desulfurizer has been used in the injection desulfurization of mixed iron cars in Baosteel Co., Ltd. steelmaking plant. In December 2013, under the same (similar) desulfurization molten iron conditions, the high-efficiency composite desulfurizer (test desulfurizer) of the present invention was expressed in mass percentage Total: quicklime 74%, limestone 5%, soda ash 8%, fluorite 8%, graphite 5%.

[0042] The relevant raw materials used must meet the physical and chemical index requirements of the raw materials, and be pre-mixed according to the above-mentioned ratio composition requirements, and grind and screen according to the requirements of particle size 100% ≤ 1.0mm, 0.15mm ≥ 90%.

[0043] Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com