Friction and shear induced chemical reaction to form a film on the surface to reduce the coefficient of friction

A friction coefficient and chemical reaction technology, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of reduced machine life, insufficient lubrication of friction pairs, slow development and application, etc., to reduce lubrication costs and prolong friction pairs. Longevity, effect of reducing chemical reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

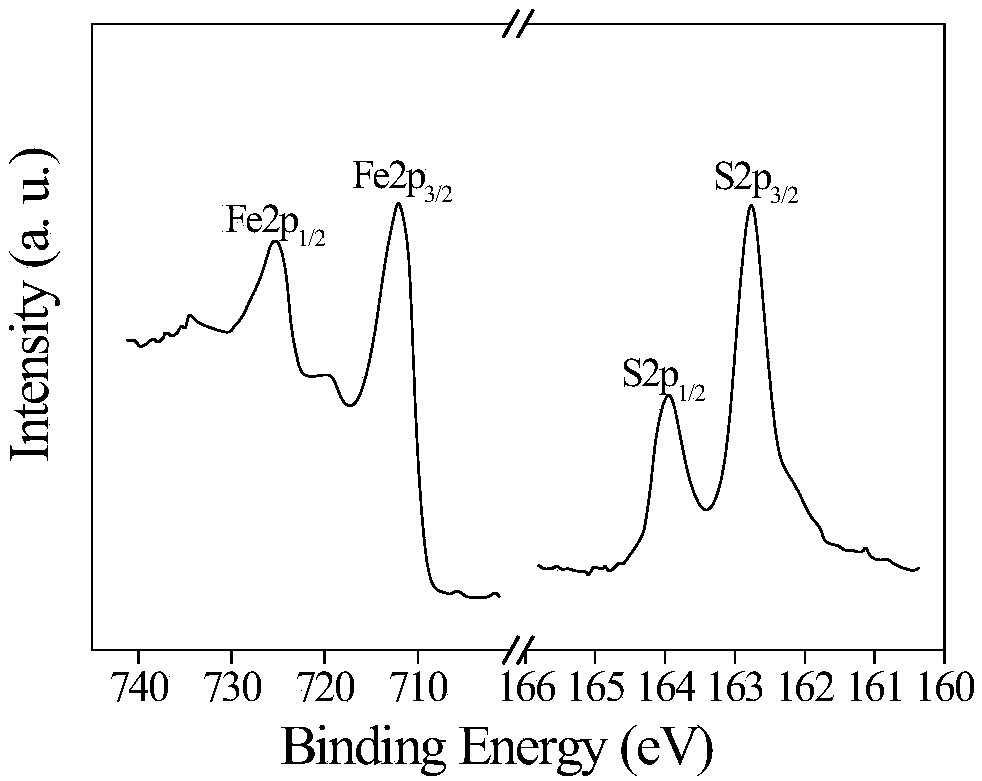

[0015] in 1×10 -10 Under Torr high vacuum environment, add dialkyl disulfide (CH 3 -S-S-CH 3 ) to 1×10 -7 Keep it for 15 minutes after Torr, then start the friction pair at room temperature 25°C, friction speed 2×10 -3 Under the conditions of m / s, load 0.8N, and stroke 1cm, reciprocating friction was carried out 50 times, and the friction coefficient of the system was reduced from 0.52 in the initial stage to 0.18. The test of the friction surface by X-ray photoelectron spectroscopy shows that ferrous sulfide was formed on the surface metal sulfide lubricating film. The friction pair mentioned here is that the upper sample is a tungsten carbide ball; the lower sample is an iron-based metal disc with a surface roughness of R a is 0.06 μm.

Embodiment 2

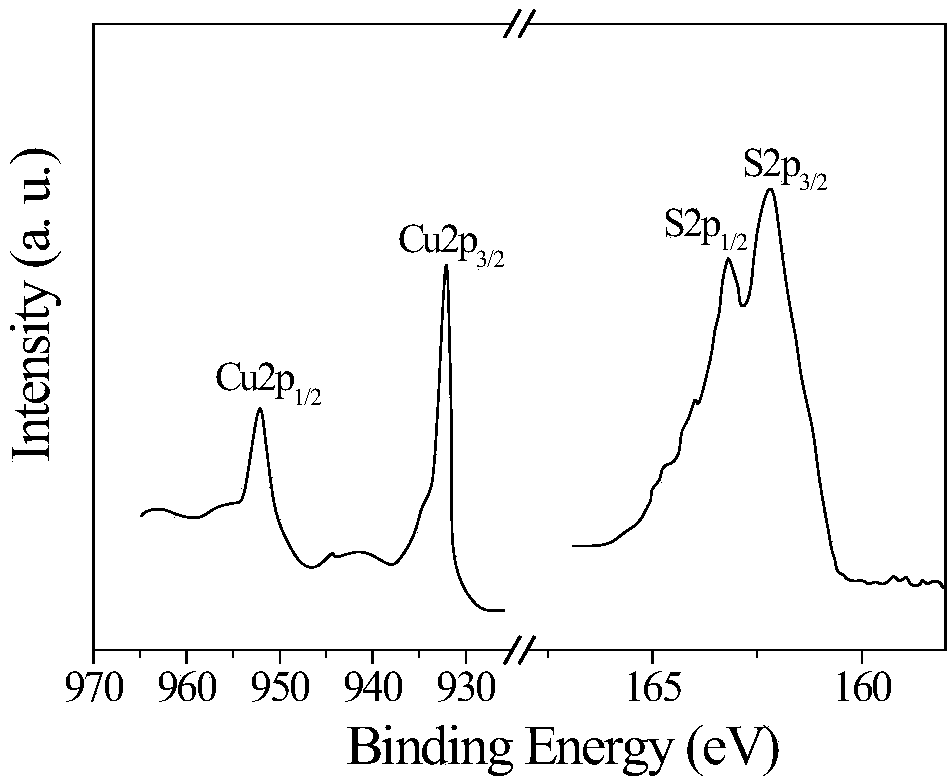

[0017] in 1×10 -10 Under Torr high vacuum environment, add dialkyl disulfide (CH 3 -S-S-CH 2 CH 3 ) to 2×10 -5 Keep it for 10 minutes after Torr, then start the friction pair at room temperature 25°C, friction speed 2×10 -3 Under the conditions of m / s, load 1N, and stroke 1cm, the reciprocating friction is performed 80 times, and the friction coefficient of the system is reduced from 0.55 in the initial stage to 0.16. The test of the friction surface by X-ray photoelectron spectroscopy shows that copper sulfide metal is formed on the surface. Sulfide lubricating film. The friction pair mentioned here is that the upper sample is a tungsten carbide ball; the lower sample is a copper-based metal disc with a surface roughness of R a 0.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com