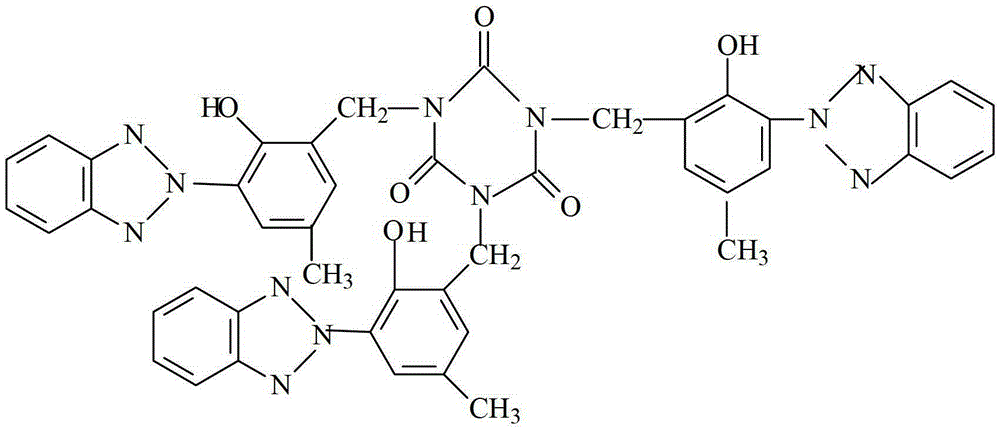

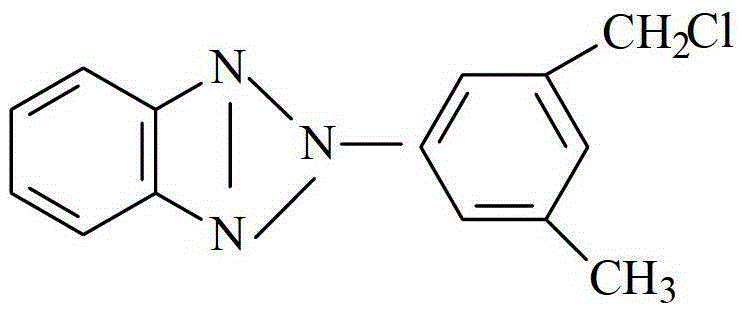

Preparation method of ultraviolet absorbent tribenzotriazole isocyanurate

A technology of isocyanuric acid tris and benzotriazoles, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of late start, limited varieties, high cost, etc., and increase the load capacity. , the effect of improving yield and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

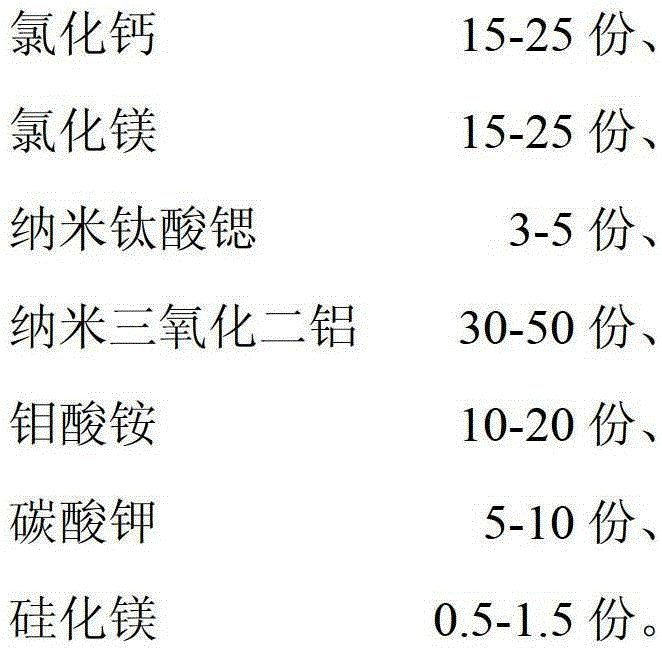

[0028] One, Al2O3 carrier solid base catalyst and preparation method through the following steps:

[0029] (a). Chemical composition: 750 parts of deionized water, 15 parts of calcium chloride, 25 parts of magnesium chloride, 3 parts of nano strontium titanate, 100 parts of 25% ammonia water, 30 parts of nano aluminum oxide, 3% ammonium molybdate 20 parts of aqueous solution, 5 parts of potassium carbonate, 1.5 parts of magnesium silicide;

[0030] (b). Dissolve calcium chloride and magnesium chloride into 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-aluminum oxide and nano-strontium titanate, and turn on the high-speed disperser at 1500 rpm / Dilute the ammonia water to 250 parts with deionized water, control the temperature of all the solutions at 10°C, then add calcium chloride, magnesium chloride solution and ammonia water to the reaction kettle dropwise at the same time, and drop them in 10 minutes. Stir at high speed f...

Embodiment 2

[0037] One, Al2O3 carrier solid base catalyst and preparation method through the following steps:

[0038] (a). Chemical composition: 750 parts of deionized water, 25 parts of calcium chloride, 15 parts of magnesium chloride, 5 parts of nano strontium titanate, 50 parts of 25% ammonia water, 50 parts of nano aluminum oxide, 3% aqueous solution of ammonium molybdate 10 parts, 10 parts of potassium carbonate, 0.5 parts of magnesium silicide;

[0039] (b). Dissolve calcium chloride and magnesium chloride into 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-aluminum oxide and nano-strontium titanate, and turn on the high-speed disperser at 2000 rpm / Dilute ammonia water to 250 parts with deionized water, control the temperature of all solutions at 20°C, then add calcium chloride, magnesium chloride solution and ammonia water to the reaction kettle dropwise at the same time, and complete the dropwise addition within 20 minutes. Sti...

Embodiment 3

[0046] One, Al2O3 carrier solid base catalyst and preparation method through the following steps:

[0047](a). Chemical composition: 750 parts of deionized water, 20 parts of calcium chloride, 20 parts of magnesium chloride, 4 parts of nano strontium titanate, 75 parts of 25% ammonia water, 40 parts of nano aluminum oxide, 3% ammonium molybdate 15 parts of aqueous solution, 7.5 parts of potassium carbonate, and 1 part of magnesium silicide;

[0048] (b). Dissolve calcium chloride and magnesium chloride in 250 parts of deionized water, add 500 parts of deionized water into the reaction kettle, add nano-aluminum oxide and nano-strontium titanate, and turn on the high-speed disperser at 1750 / min , Dilute ammonia water to 250 parts with deionized water, control the temperature of all solutions at 15°C, then add calcium chloride, magnesium chloride solution and ammonia water to the reaction kettle dropwise at the same time, and drop them in 15 minutes. Stir at high speed for 1.5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com