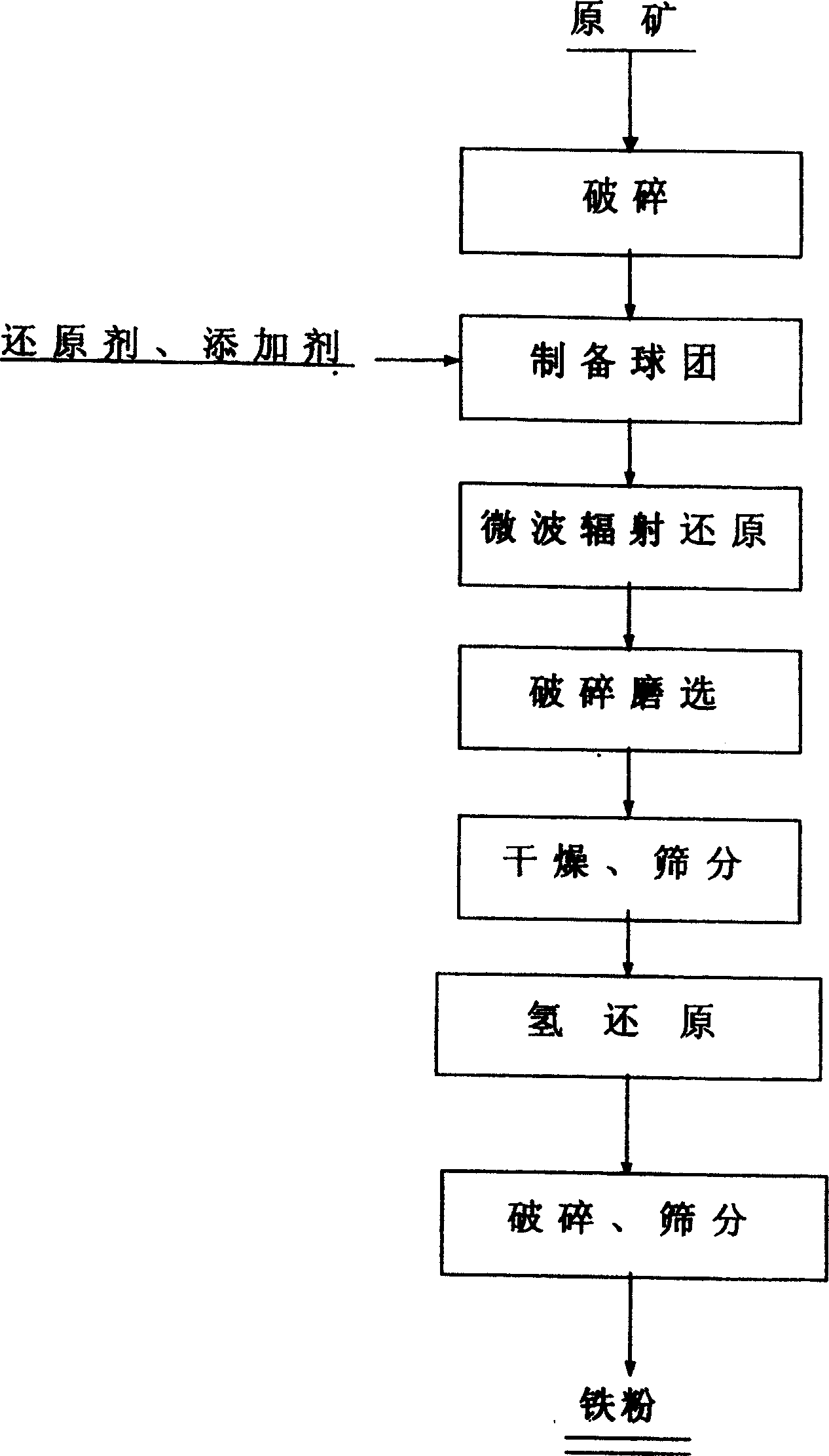

Method for preparing natural micro alloy iron powder from vanadium-titanium-iron headings by microwave radiation

A technology of vanadium-titanium-iron concentrate and microalloyed iron powder, which can be used in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of unsatisfactory; Panzhihua Mining Company, high consumption of refractory materials, low yield and other problems, achieve The effect of shortening reduction time, high heating efficiency and fast heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Raw material chemical composition: TFe 65.32~68.67%, V 2 o 5 0.55~0.62%, TiO 2 11.56~12.42%, SiO 2 4.89~5.23, Al 2 o 3 4.81-4.94%, CaO 1.38-1.65%, MgO 3.10-3.75%.

[0015] The raw material is crushed into a powder with a particle size of less than 75um, accounting for 60%, and the powder is equipped with coke accounting for 10% of the weight of vanadium-titanium iron concentrate, 5% additive sodium sulfate (Na 2 SO 4 ), made into pellets with a diameter of 0.8-1.1cm; the pellets were dried at a temperature of 130-140°C for 30 minutes; after drying, the pellets were reduced in a microwave oven with a microwave power of 700W and a frequency of 2450MHz. The reducing agent coke of 30% of the weight of the concentrate, the reduction temperature of the pellets is 1100-1150 ° C, and the reduction time is 60 minutes; after that, the pellets are ball milled and sieved to a powder with a particle size of less than 180um; reduced with hydrogen in a muffle furnace, The am...

Embodiment 2

[0017] Raw material chemical composition TFe 64.37~67.56%, V 2 o 5 0.52~0.59%, TiO 2 11.76~12.95%, SiO 2 4.82~5.19, Al 2 o 3 4.64-4.73%, CaO 1.42-1.59%, MgO 3.34-3.69%.

[0018] The raw material is crushed into a powder whose particle size is less than 75um and accounts for 80%. The powder is equipped with coke accounting for 15% of the weight of vanadium-titanium iron concentrate, 5% additive sodium sulfate (Na 2 SO 4 ), 3% iron powder; make pellets with a diameter of 0.9-1.2cm, and dry the pellets at a temperature of 140-150°C for 35 minutes; after drying, the pellets are reduced in a microwave oven with a microwave power of 700W and a frequency of 2450MHz The reductant coke that accounts for 40% of the weight of vanadium-titanium iron ore concentrate is mixed, the reduction temperature of the pellets is 1200-1250 ° C, and the reduction time is 90 minutes; after that, the pellets are ball milled and sieved to a powder with a particle size of less than 180um; in the ...

Embodiment 3

[0020] Raw material chemical composition TFe 66.87~69.17%, V 2 o 5 0.49~0.58%, TiO 2 11.95~12.37%, SiO 2 4.95~5.21, Al 2 o 3 4.71~5.03%, CaO 1.49~1.60%, MgO 3.42~3.62%;

[0021] The raw material is crushed into a powder whose particle size is less than 75um and accounts for 90%. The powder is equipped with coke accounting for 20% of the weight of vanadium-titanium iron concentrate, 3% additive sodium sulfate (Na 2 SO 4 ), 5% iron powder; make pellets with a diameter of 1.0-1.3cm, and dry the pellets at a temperature of 130-150°C for 40 minutes. After drying, the pellets are reduced in a microwave oven with a microwave power of 700W and a frequency of 2450MHz. Reductant coke accounting for 40% of the weight of the vanadium-titanium iron concentrate, the reduction temperature of the pellets is 1200-1300 ° C, and the reduction time is 90 minutes; after that, the pellets are ball milled and sieved to a powder with a particle size of less than 180um; in the muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com