Gas-liquid two-phase flow measuring device and method based on phase segmentation and image processing

A flow measurement device, gas-liquid two-phase flow technology, applied in the direction of measurement devices, liquid/fluid solid measurement, flow/mass flow measurement, etc., can solve the problem of low resolution of soft field characteristics, poor real-time measurement, and signal nonlinearity Analyzing and other problems to achieve the effect of overcoming the difficulty in determining the gas content of the section, saving material costs, and improving the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in more detail below in conjunction with the accompanying drawings.

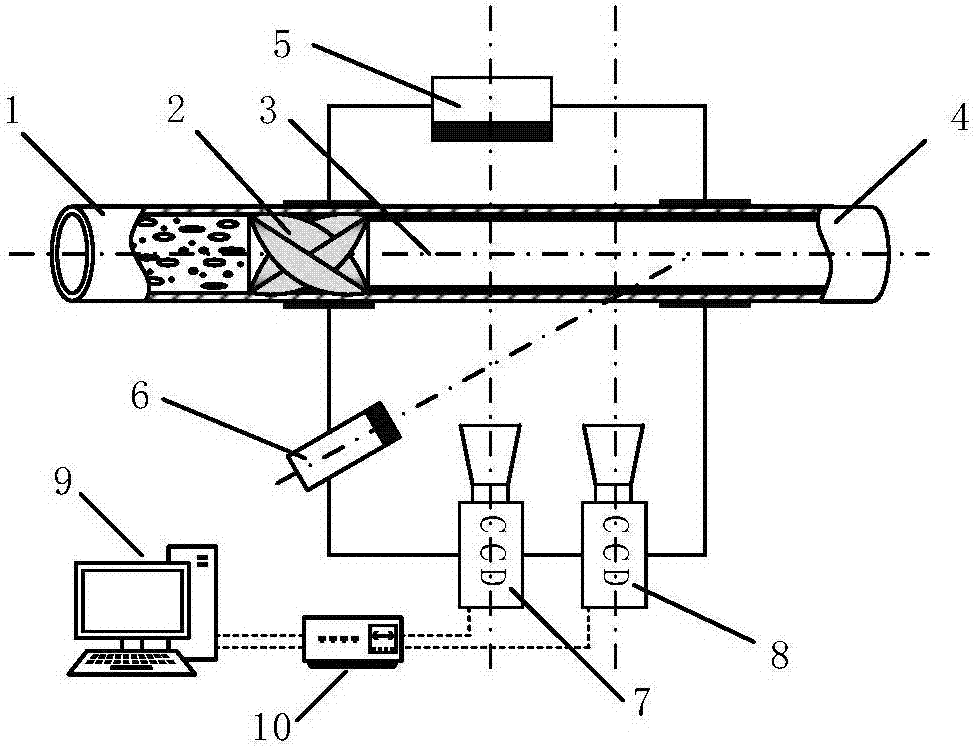

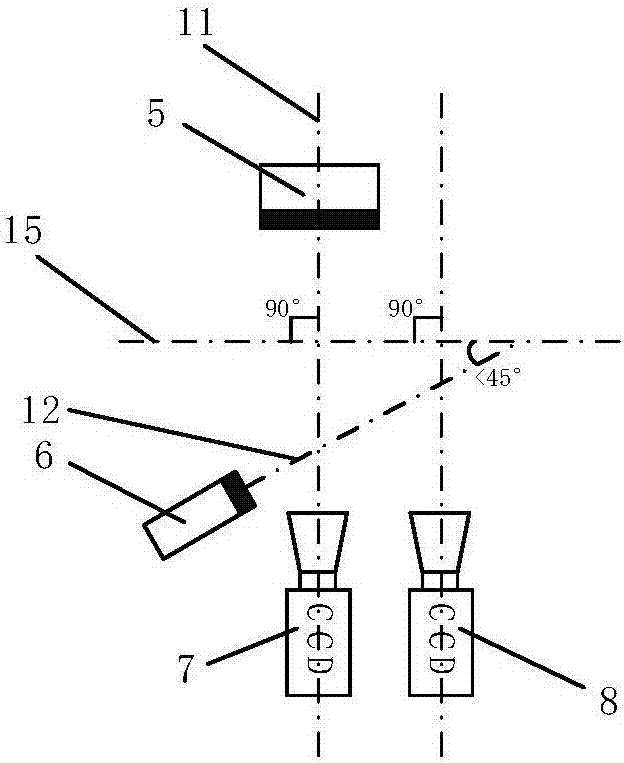

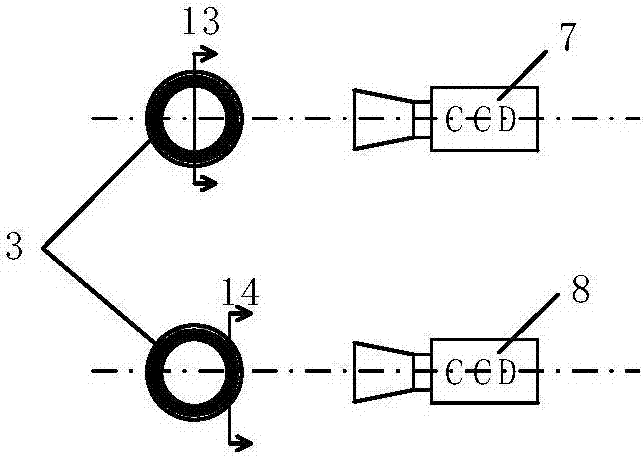

[0037] Such as figure 1 As shown, the present invention is a gas-liquid two-phase flow measurement device and method based on phase separation and image processing, wherein the measurement device includes an inlet section 1, a measuring pipe section 3 and an outlet section 4, all of which are made of light-transmitting materials, which are sequentially connected. , the swirl device 2 is fixed on the inner wall of the measuring pipe section 3, and the swirl device 2 is relatively stationary with the measuring pipe section 3; it also includes an industrial camera-7 and an opposite parallel light source 5 respectively arranged on both sides of the measuring pipe section 3, arranged on The second industrial camera 8 and the parallel light source 6 on the same side of the measuring pipe section 3, the synchronous controller 10 connected to the first industrial camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com