A method for evaluating the mechanical failure degree of frame circuit breakers based on vibration signals

A frame-type circuit breaker and vibration signal technology, which is applied in circuit breaker testing, mechanical component testing, instruments, etc., can solve the problem of not fundamentally revealing the signal characteristics and the change rule of the fault degree, the judgment of the fault degree, and the power outage accident. Economic and other issues, to achieve the effect of guiding equipment maintenance and improving the degree of mechanical failure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

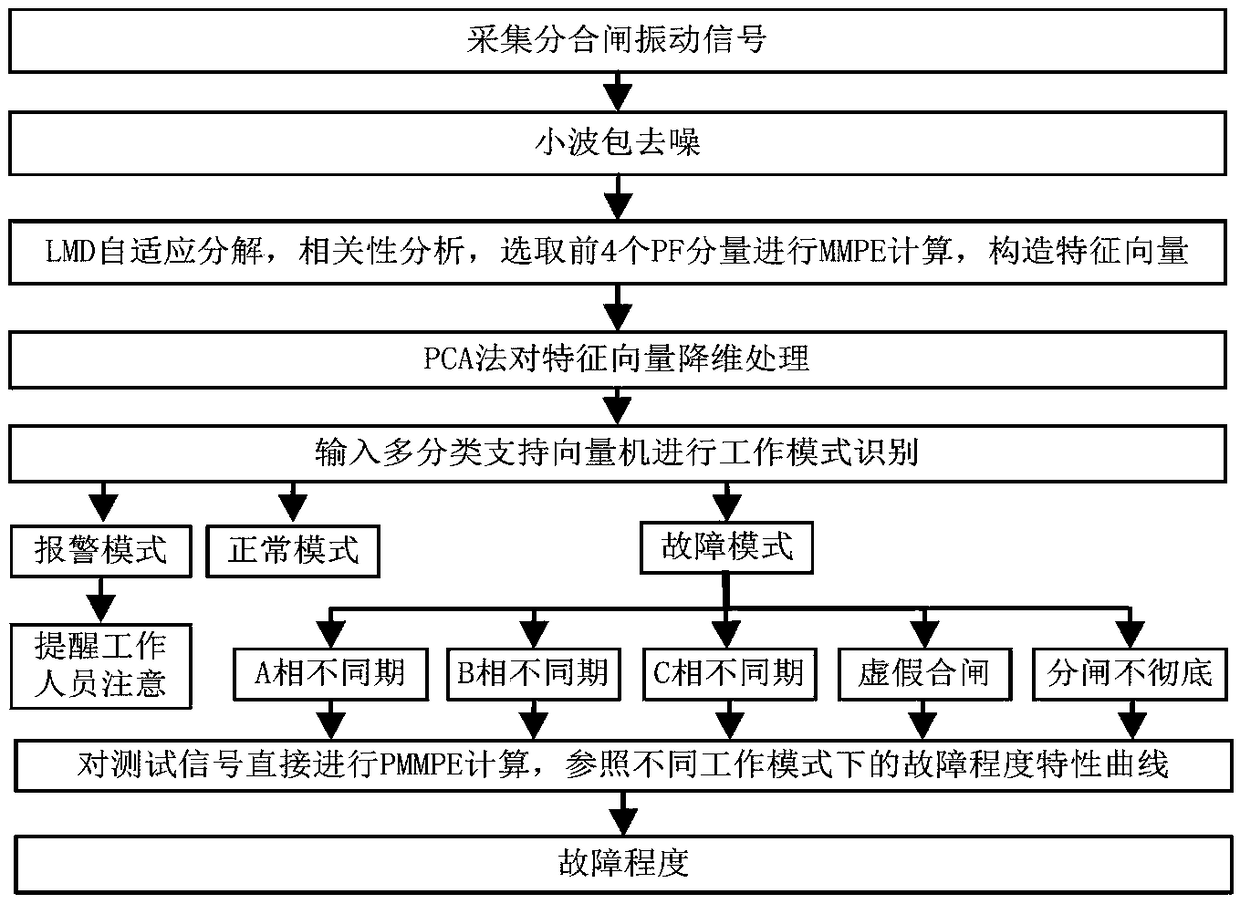

Method used

Image

Examples

Embodiment 1

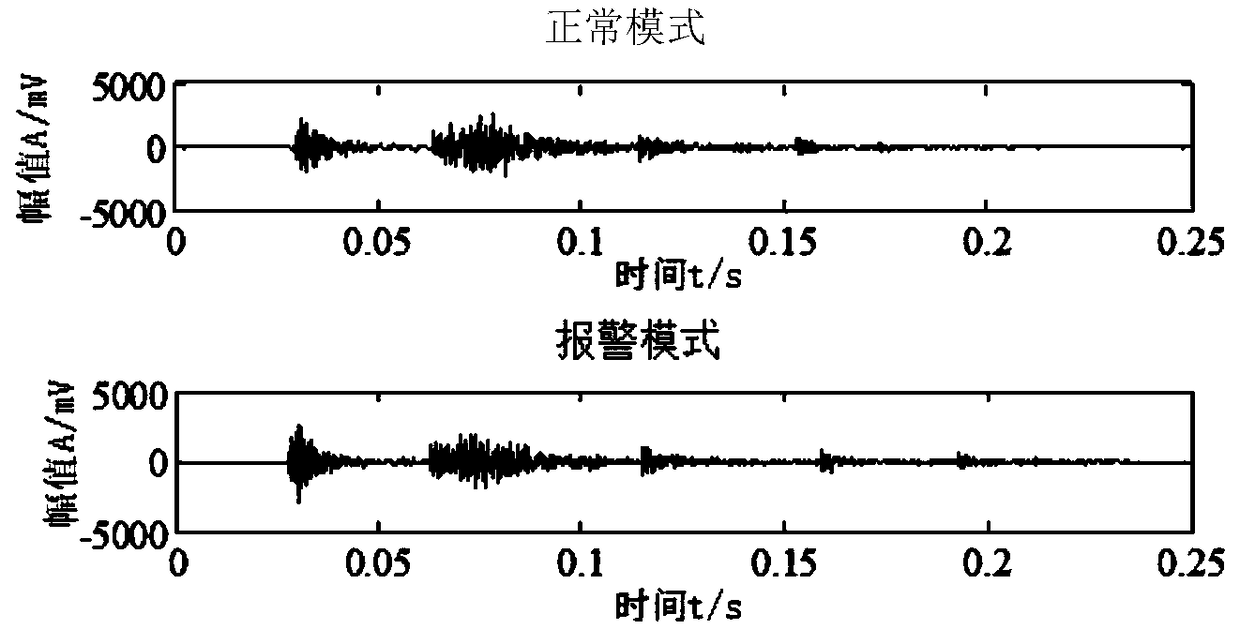

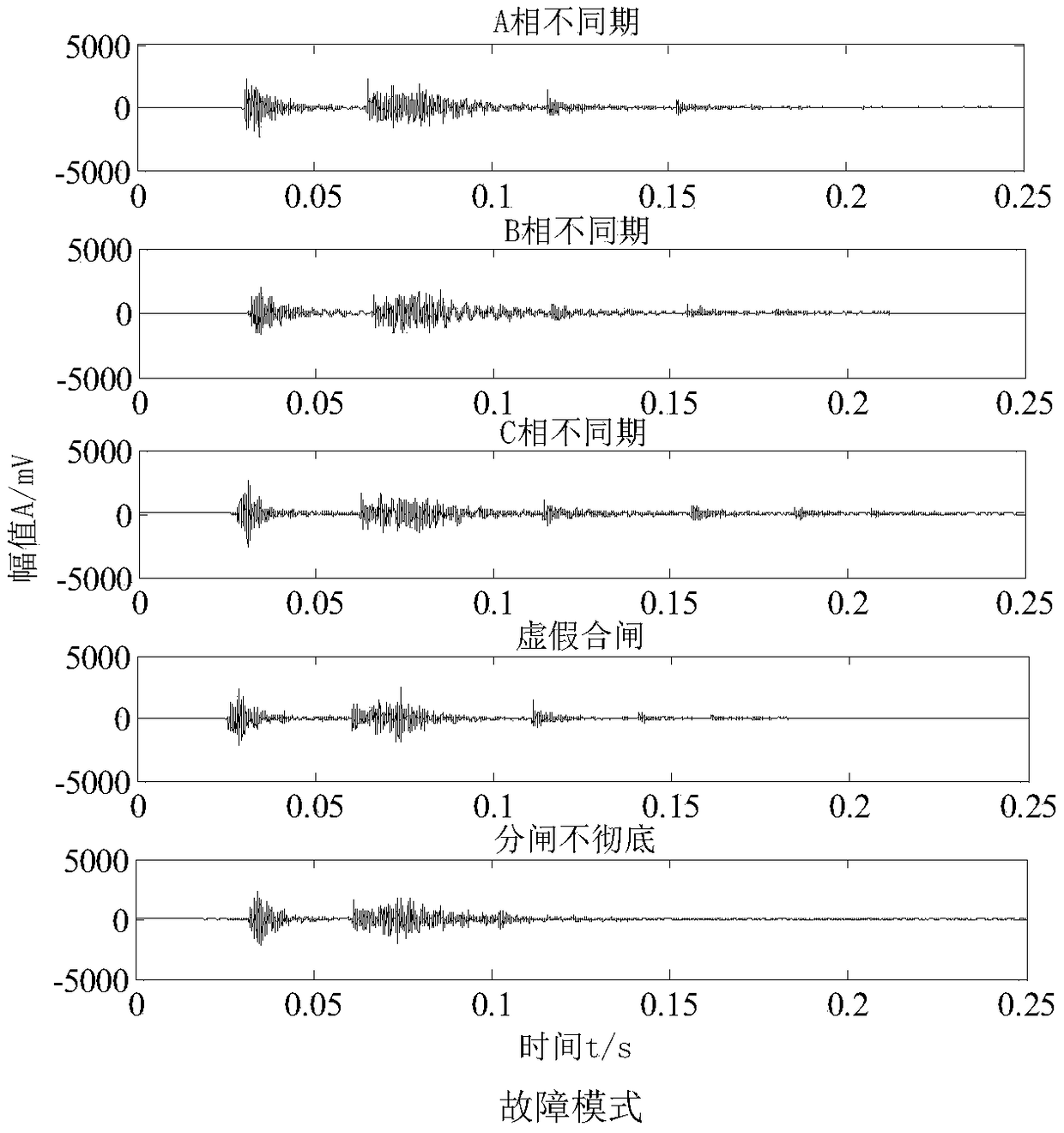

[0131] In this example, a frame-type circuit breaker with a model DW15-1600 with strong mechanical structure visualization is used as the test object. This circuit breaker is suitable for distribution networks with a rated operating voltage of 380V and 50Hz, a rated current of 1600A, and a spring switch mechanism. operating mechanism. The opening and closing faults of the circuit breaker are mainly manifested in the action time exceeding the regulations, and the typical opening and closing faults can be simulated by adjusting the opening distance and overtravel between the contacts. Separately adjust the connecting rod length of the three-phase contacts to simulate the three-phase non-synchronous failure caused by mechanism wear or improper adjustment, that is, adjust the difference between the overtravel of a certain phase contact and the other two phase contacts through the retreat distance of the connecting rod; adjust the contact The cantilever of the head system simulates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com