Gem-grade large monocrystal diamond multi-cavity composite structure, and preparation method and application thereof

A single crystal diamond, multi-cavity technology, applied in the application of ultra-high pressure process, etc., to achieve the effect of reducing cost, saving power and energy consumption, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

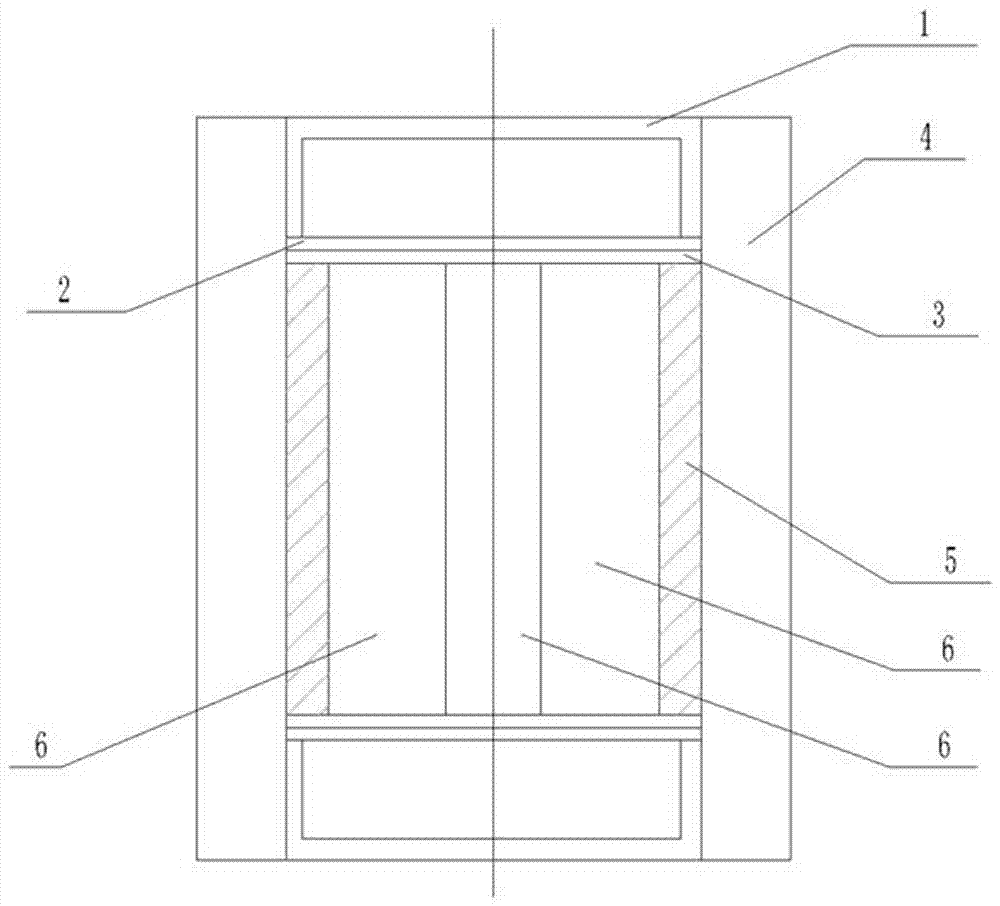

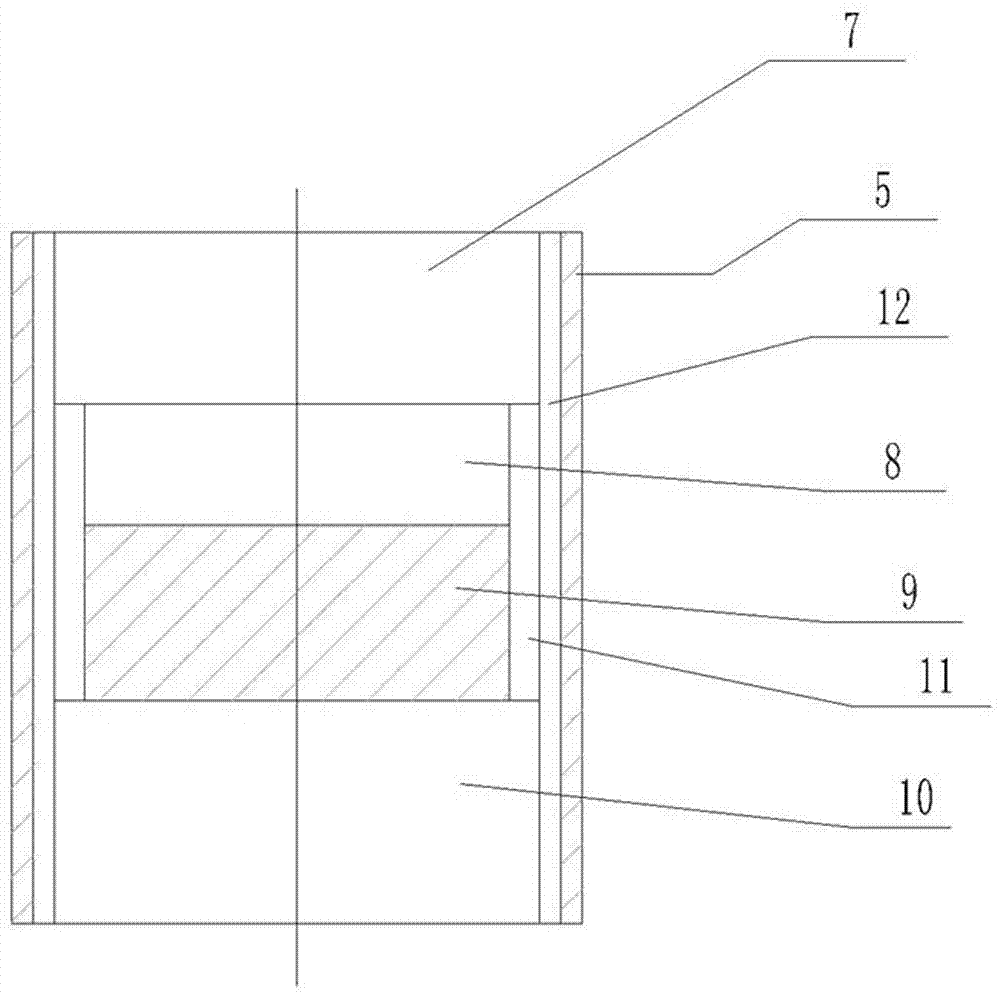

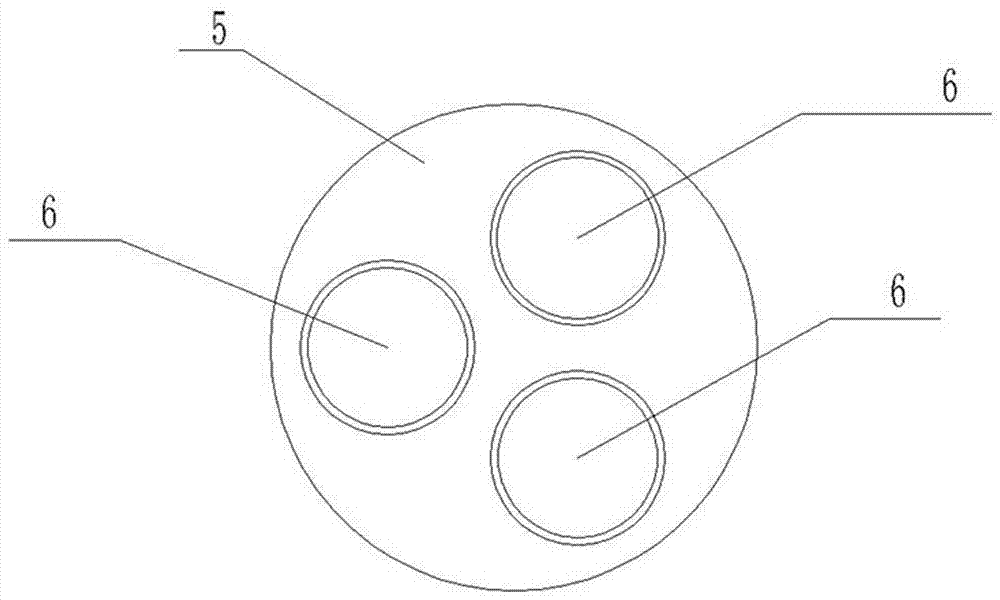

[0045] See attached Figure 1~3 As shown, the gem-grade large single crystal diamond multi-cavity composite structure of the present invention includes a pressure transmission block 4 provided with an assembly cavity, an insulator 5 is arranged in the assembly cavity, and conductive plug assemblies are symmetrically arranged at the upper and lower ends of the insulator 5, and the conductive plug components are electrically conductive. The plug assembly includes a heating sheet 3, a metal sheet 2 and a conductive plug 1 arranged in sequence. The heating sheet 3 is connected to the heating pipe 12; the insulator 5 is provided with a plurality of cylindrical synthesis cavities 6, and the height of the cylindrical synthesis cavities 6 is equal to that of the insulator. 5. The height is consistent; a large single crystal growth component is arranged in the cylindrical synthesis chamber 6;

[0046] The large single crystal growth assembly comprises a crystal bed 10, a catalyst sheet...

Embodiment 2

[0047] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0048] The heating sheet 3 is a sheet structure cut from high-purity graphite carbon rods; the heating tube 12 is a tube structure formed by high-purity graphite carbon rods, and the thickness of the tube wall is 1.2 ~2.0mm.

Embodiment 3

[0049] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0050] The heating sheet 3 is a sheet structure cut from high-purity graphite carbon rods; the heating tube 12 is a tube structure formed by high-purity graphite carbon rods, and the thickness of the tube wall is 1.2 ~2.0mm; the insulator is a cylinder formed by mixing and pressing sodium chloride powder and zirconia powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com