Double-layer silsesquioxane epoxy resin modifier and its preparation method and application

The technology of siloxane epoxy resin and silsesquioxane is applied in the field of double-layer silsesquioxane epoxy resin modifier and its preparation, which can solve the problems of reducing the toughness of hybrid materials and achieve molecular flexibility. Good properties, good dispersibility, and the effect of improving toughness and heat-and-moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation process of hydrogen-containing double-layer silsesquioxane is to mix phenyltrimethoxysilane, sodium hydroxide, and water in a certain proportion, use isopropanol as a solvent to reflux for 4 hours, filter and dry to obtain DDSQ-Na; The molar ratio of phenyltrimethoxysilane, sodium hydroxide and water is 4:2:5. Cool DDSQ-Na and triethylamine in tetrahydrofuran as a solvent in an ice-water bath to below 0°C, blow nitrogen gas and slowly add methyldichlorosilane, react in an ice-water bath for 1 hour, and post-process to prepare hydrogen-containing double-layer sesqui Siloxane; wherein the molar ratio of DDSQ-Na, triethylamine and methyldichlorosilane is 1:1:2; the post-treatment process is sequentially washed with water, hydrochloric acid, and saturated sodium bicarbonate, washed three times with water, and distilled Then wash with 100ml of methanol three times and dry in vacuum to obtain the product.

[0045]The preparation process of allyl bisphenol A e...

Embodiment 1

[0047] 10g of allyl bisphenol A epoxy resin and 0.14g of Castel catalyst (50ppm) were added to 100ml of toluene, and the temperature was raised to 75°C under the protection of nitrogen, and then 14.4g of hydrogen-containing double layers dissolved in 100ml of toluene were doubled The semisiloxane was added slowly within 2 hours, and the reaction was continued for 12 hours after the dropwise addition was completed. The solvent is distilled off under reduced pressure to obtain a double-layer silsesquioxane epoxy resin modifier, which is denoted as EPDDSQ-1, and the n value is 1 (formula I type).

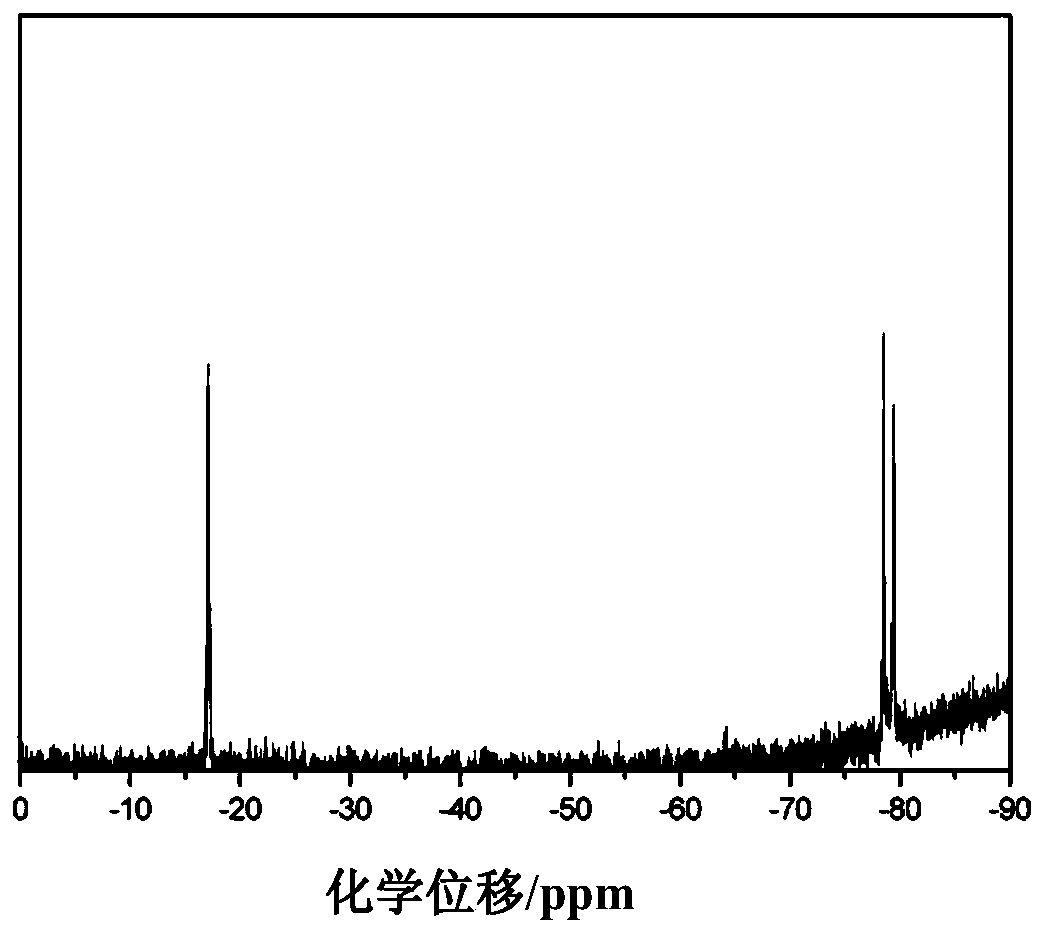

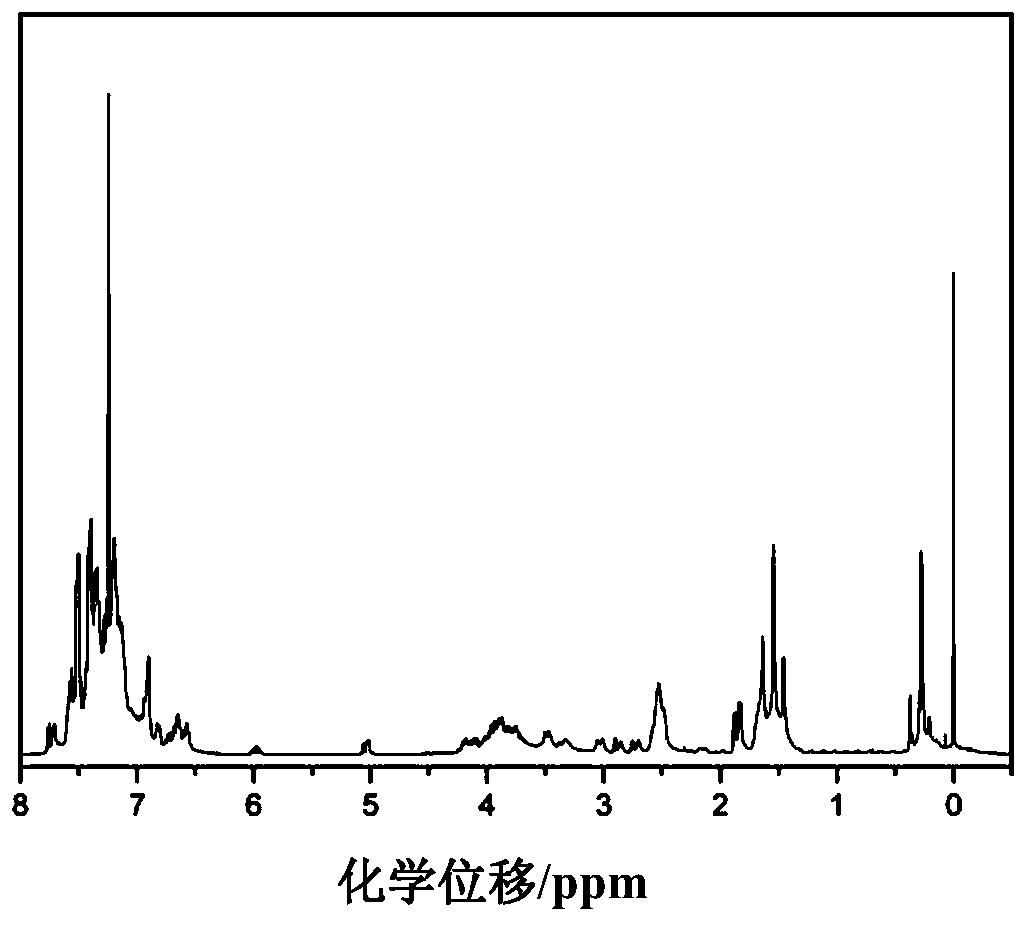

[0048] The silicon spectrum and hydrogen spectrum of the product prepared in this embodiment are respectively as follows figure 1 , 2 Shown, and determine the epoxy value in its molecular structure by titrating the epoxy value to be 2.01mmol / g.

[0049] Dissolve 50g E51 epoxy resin, 18.5g DDS epoxy resin curing agent and 3.45g EPDDSQ-1 in acetone at 50°C and disperse evenly, then rem...

Embodiment 2

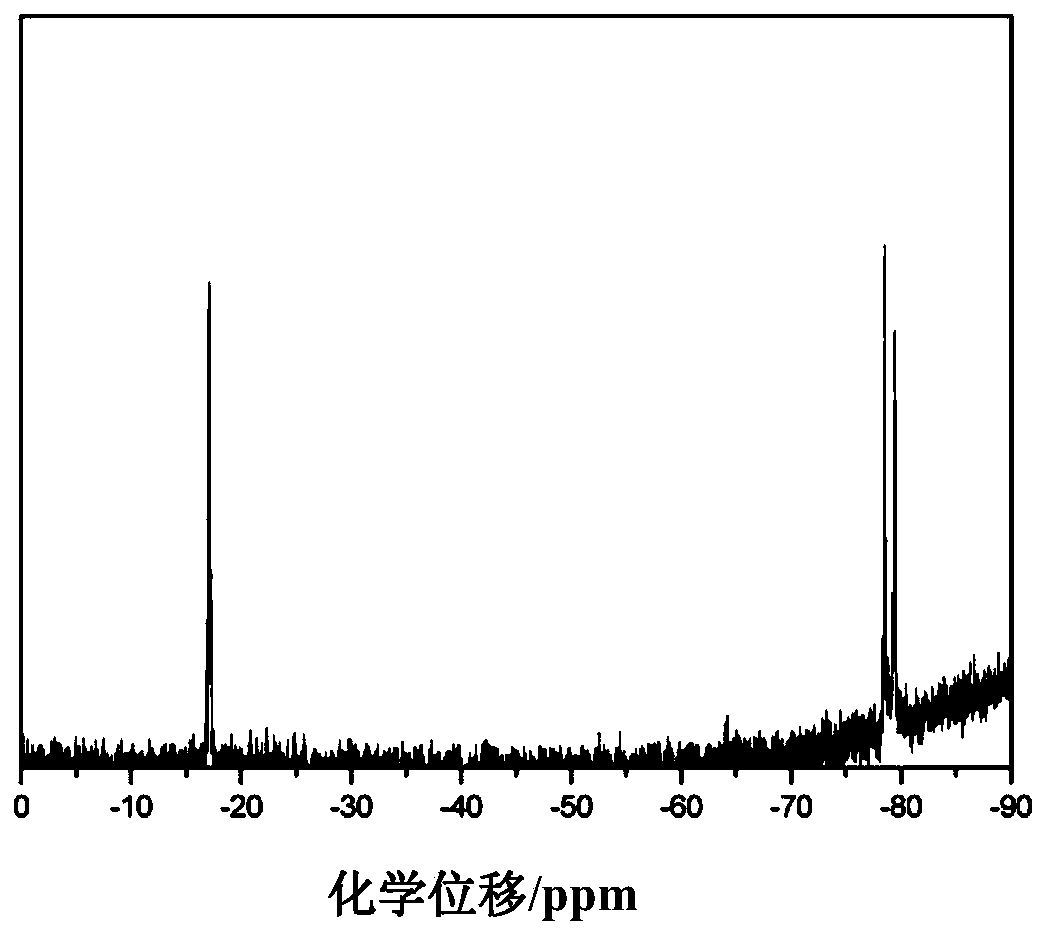

[0051] 10g of allyl bisphenol A epoxy resin and 0.14g of Castel catalyst (50ppm) were added to 100ml of toluene, and the temperature was raised to 75°C under the protection of nitrogen, and then 19.2g of hydrogen-containing double layers dissolved in 100ml of toluene were doubled The semisiloxane was added slowly within 2 hours, and the reaction was continued for 12 hours after the dropwise addition was completed. The solvent is removed by distillation under reduced pressure to obtain the product EPDDSQ2, the n value is 2 (formula I type), and the epoxy value is 1.68mmol / g.

[0052] Dissolve 50g of E51 epoxy resin, 18.5g of DDS epoxy resin curing agent and 3.45g of EPDDSQ2 in acetone at 50°C and disperse evenly, then remove the solvent in vacuum at 90°C, cast it in a steel mold, at 140°C Cure for 2 hours at 160°C for 2 hours and 180°C for 2 hours. The sample released from the mold has no bubbles, and the appearance is transparent without obvious defects. The properties of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com