High-transparency slippery PET sheet material and manufacture method thereof

A transparent and smooth technology, used in flat products, other household appliances, applications, etc., can solve the problems of low quality, easy aging, and poor smoothness of PET sheets, achieve good UV resistance, ensure high transparency, The effect of ensuring slippery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

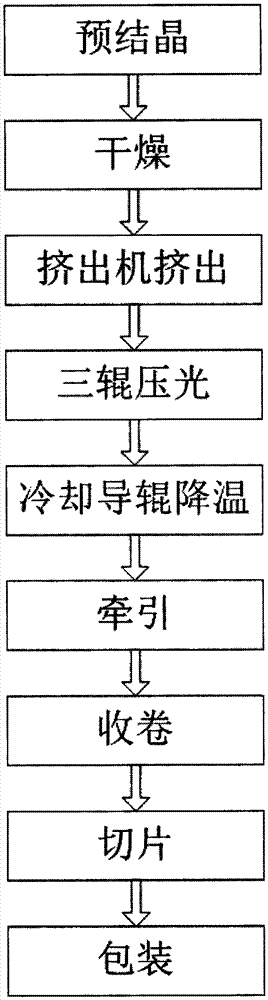

Image

Examples

Embodiment 1

[0035] A kind of manufacture method of highly transparent smooth PET sheet, comprises the steps:

[0036] Step 1, pre-crystallization, the PET crystallization temperature is set at 155°C, the hot air dew point is controlled at -40°C, the time is controlled at 80min, and the pre-crystallization temperature is 10°C lower than the drying temperature;

[0037] Step 2, drying, PET is dried with a dehumidifying dryer, the air is heated to 165°C, the time is controlled at 5hr, the dew point of the hot air of the dehumidifying dryer is controlled at -45°C, and the moisture content after drying must be lower than 0.003% (30ppm). The air flow after drying is maintained at 3m 3 / kg·hr;

[0038] Step 3, extruding from the extruder, mixing the raw materials evenly according to the proportion, a kind of highly transparent and smooth PET sheet, its raw material components are calculated in weight percentage: 0.5% of transparent additive, 3% of smooth masterbatch, anti- 0.9% of ultraviolet ...

Embodiment 2

[0046] A kind of manufacture method of highly transparent smooth PET sheet, comprises the steps:

[0047] Step 1. Pre-crystallization, the PET crystallization temperature is set at 145°C, the hot air dew point is controlled at -45°C, the time is controlled at 40min, and the pre-crystallization temperature is 10°C lower than the drying temperature;

[0048] Step 2, drying, PET is dried with a dehumidification dryer, the air is heated to 155°C, the time is controlled at 7hr, the dew point of the hot air of the dehumidification dryer is controlled at -40°C, and the moisture content after drying must be lower than 0.003% (30ppm). The air flow rate after drying is maintained at 3.7m 3 / kg·hr;

[0049] Step 3: extruding from the extruder, mixing the raw materials evenly according to the proportion, a kind of highly transparent and smooth PET sheet, its raw material components are calculated in weight percentage: 0.2% of transparent additive, 1% of smooth masterbatch, anti- 0.5% of...

Embodiment 3

[0057] A kind of manufacture method of highly transparent smooth PET sheet, comprises the steps:

[0058] Step 1. Pre-crystallization. The PET crystallization temperature is set at 150°C, the hot air dew point is controlled at -43°C, the time is controlled at 60 minutes, and the pre-crystallization temperature is 5°C lower than the drying temperature;

[0059] Step 2, drying, PET is dried with a dehumidification dryer, the air is heated to 160°C, the time is controlled at 6hr, the dew point of the hot air in the dehumidification dryer is controlled at -43°C, and the moisture content after drying must be lower than 0.003% (30ppm). The air flow after drying is maintained at 3.5m 3 / kg·hr;

[0060] Step 3: extruding from the extruder, mixing the raw materials evenly according to the proportion, a kind of highly transparent and smooth PET sheet, its raw material components are calculated in weight percentage: 0.3% of transparent additive, 2% of smooth masterbatch, anti-corrosion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com