Square steel pipe sand pebble ring beam-construction column construction method for masonry structure houses in villages and towns

A technology of masonry structure and construction method, applied in building structure, truss structure, column and other directions, can solve the problems of difficult quality assurance, non-renewable utilization, complex construction process, etc., and achieves short construction period, low cost, and constraints obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

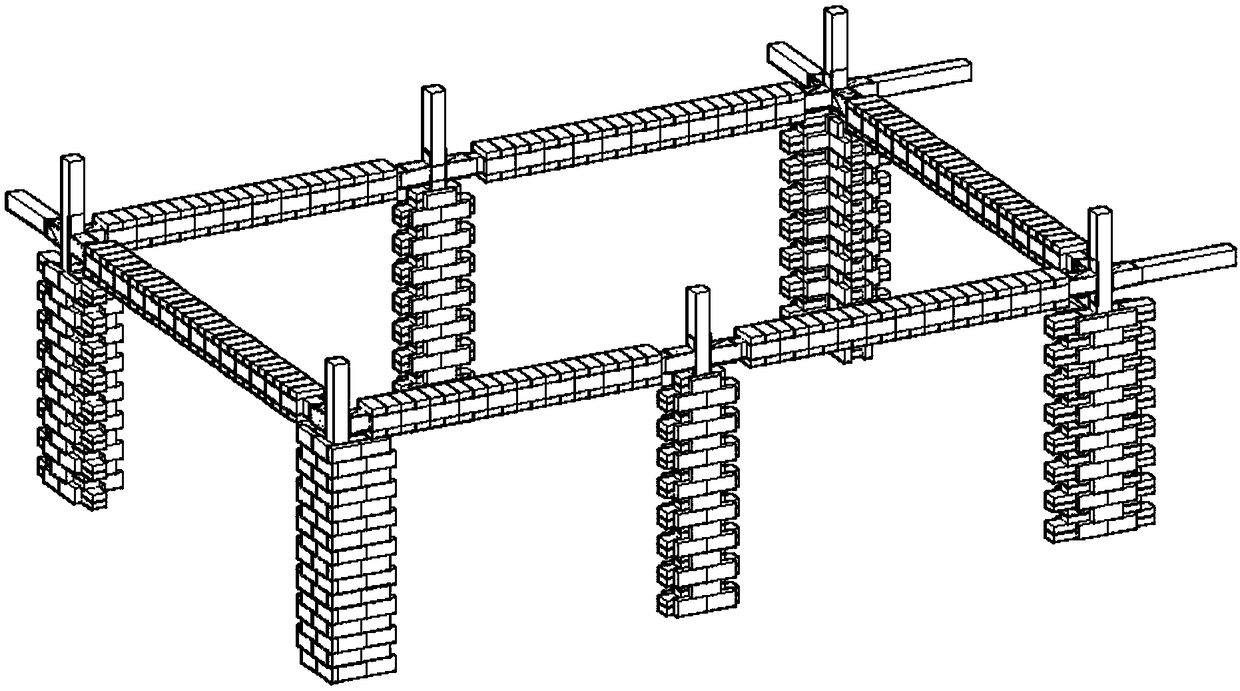

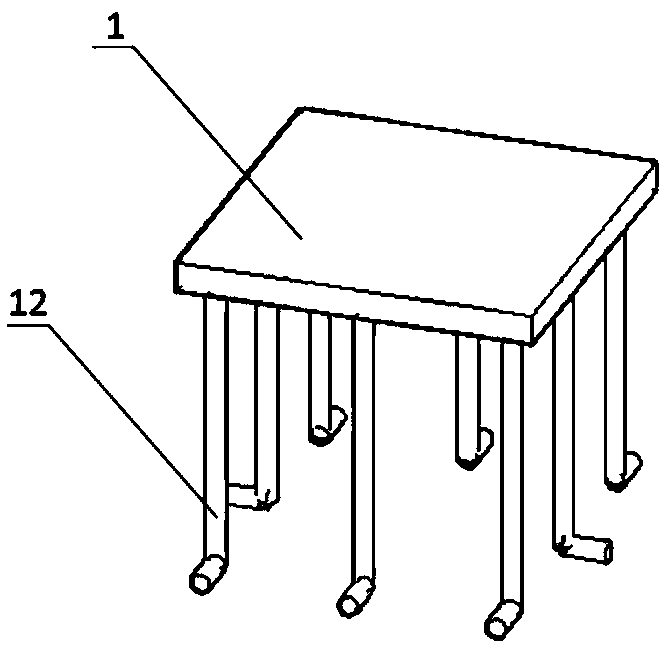

[0048] Such as Figure 1-23 Shown, a kind of village and town masonry structure square steel pipe sand pebble circle beam-structural column construction method, comprises the following steps:

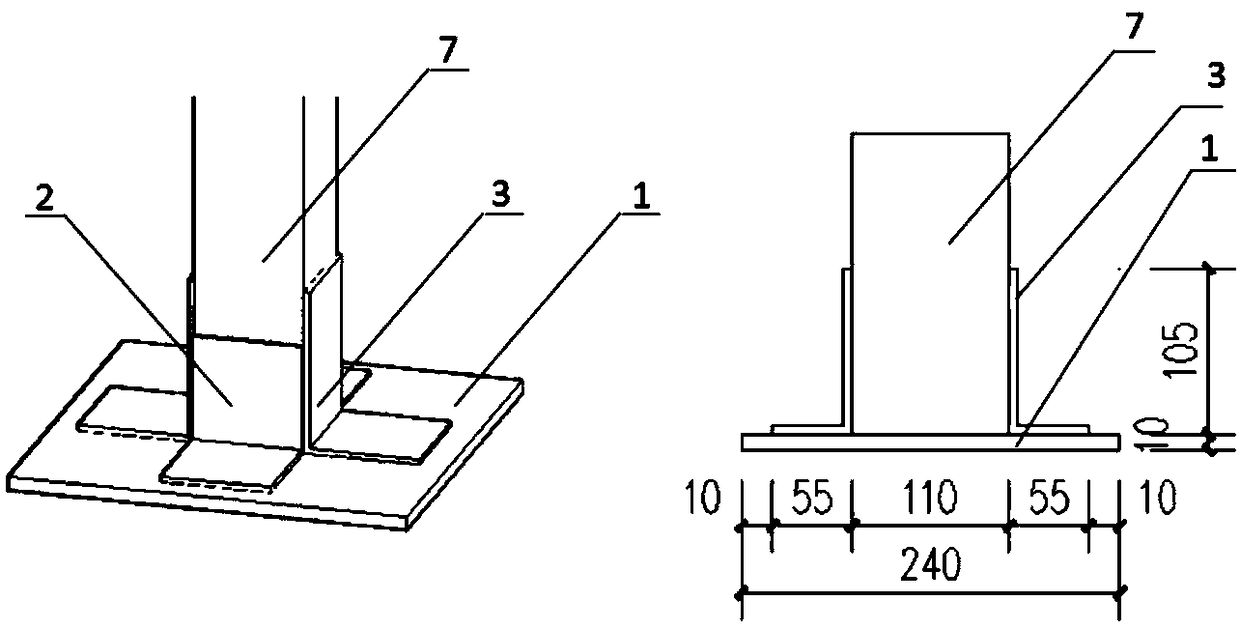

[0049] Step 1. Production of the following components: Steel plate anchors 1 for connecting square steel pipes of structural columns to the foundation, L-shaped steel plate connectors 2 and 3 of different sizes, extended butt joint connectors 4 of square steel pipes, ring beams, structural column spans or heights < 3600mm square steel tube end connector 5, ring beam, structural column span or height ≥ 3600mm square steel tube end connector 6, square steel tube for structural column (110mm×110mm×5mm) 7 and square steel tube for ring beam (110mm×110mm×5mm) 8, used for ring beams on the top floor, structural column spans or heights < 3600mm square steel pipe end connectors 9, used for top floor ring beams, structural column spans or heights ≥ 3600mm Steel pipe end connector 10; and equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com