Multiple drying tunnel type oven having waste gas filtration function

An exhaust gas filtration and tunnel-type technology, which is applied in drying solid materials, drying cargo processing, drying gas layout, etc., can solve the problems of incomplete drying, low drying efficiency, electricity consumption, etc., to reduce production costs, compact structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings and taking the drying of the positive pole piece of a lithium battery as an example.

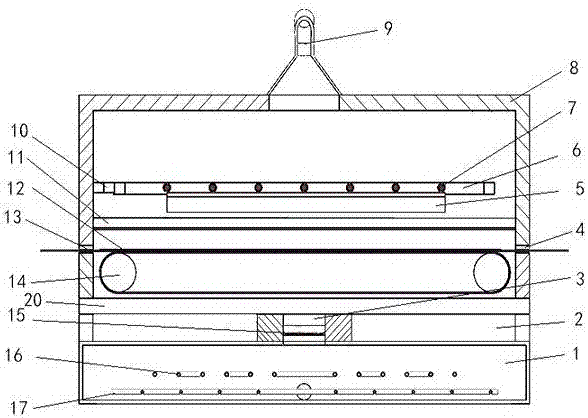

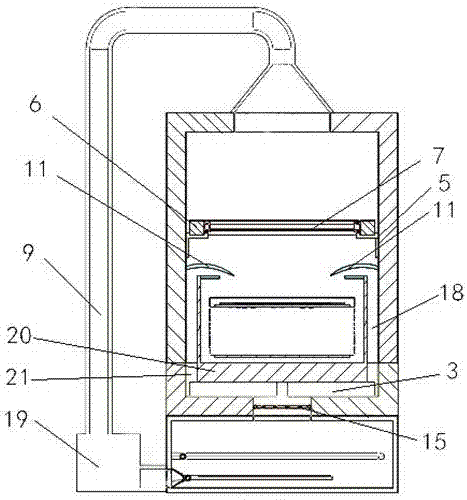

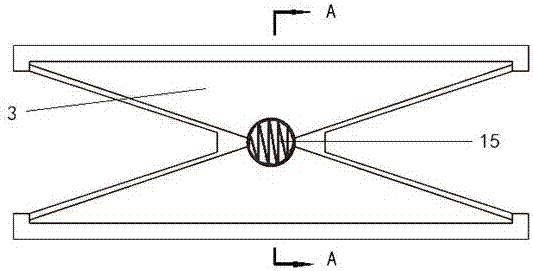

[0021] figure 1 , figure 2 As shown, the multi-drying tunnel oven with waste gas filtering function is composed of three parts: drying box 8, ventilation box 2 and filter box 1 from top to bottom, and exhaust pipeline 9 connects drying box 8 and filter box 1 connected.

[0022] The right side wall of the drying box 8 has a feed port 4, and the left side wall of the drying box 8 has a discharge port 13. The conveyor belt 12 is wound on the left and right rollers 14 and is positioned between the inlet and the discharge port. The height is slightly higher than the height of the inlet and outlet;

[0023] There are side air inlet channels 18 on the front and rear side walls of the drying box 8, and an air-introduction baffle 11 is installed on the upper part of the air inlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com