Mixed ventilation direct air-cooling system vertically arranged outside air-cooling condenser tower

An air-cooled condenser, vertically arranged technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of reduced power generation, poor cooling capacity of air-cooled condensers, and reduced heat exchange efficiency of air-cooled islands, etc. Achieve the effect of reducing installation and maintenance costs, improving summer cooling capacity, and improving flow heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention proposes a mixed ventilation direct air cooling system vertically arranged outside the air-cooled condenser tower, which will be described below with reference to the accompanying drawings.

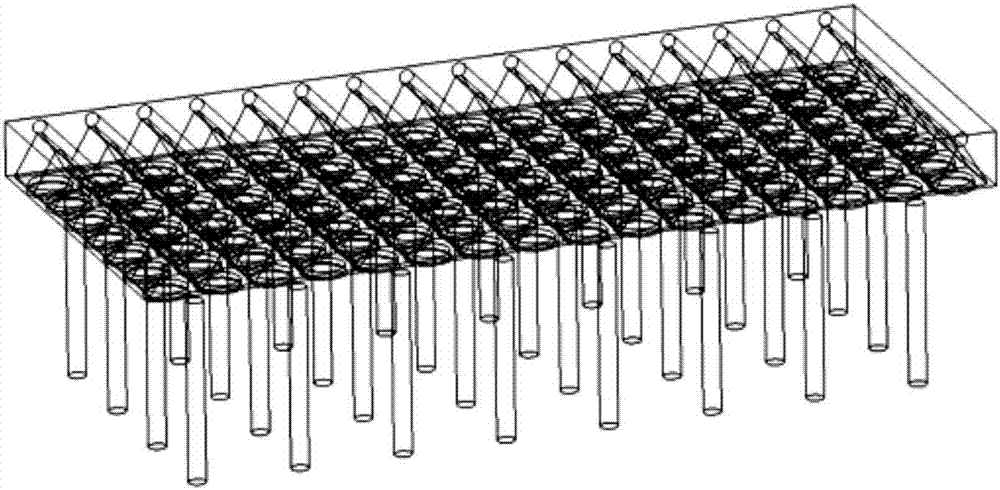

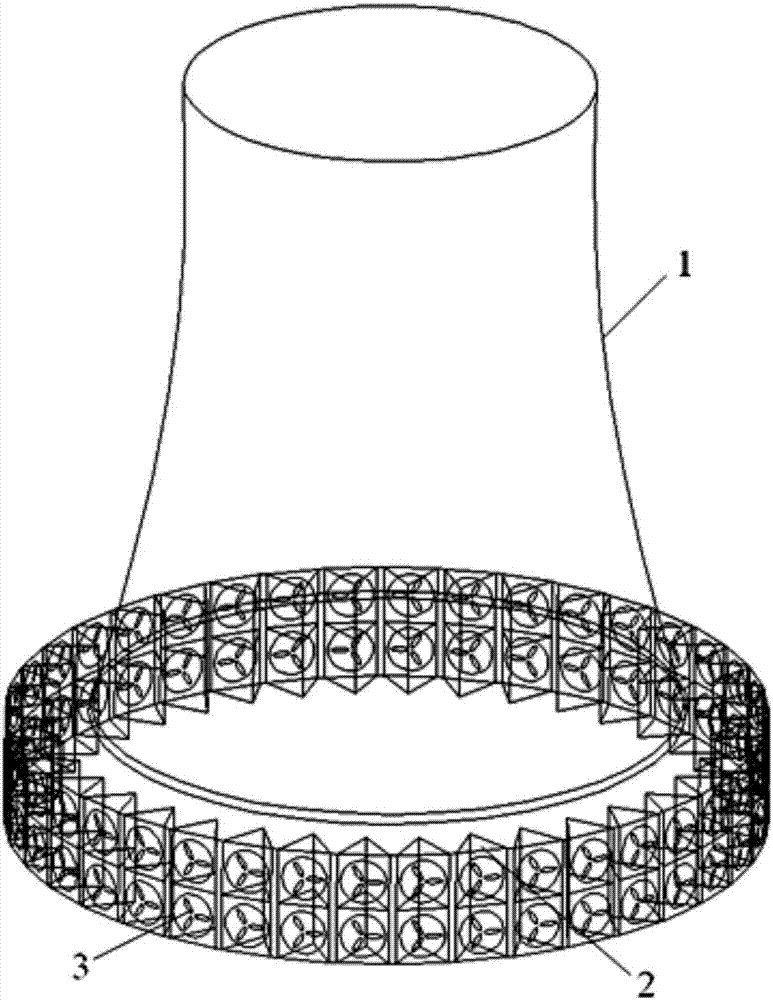

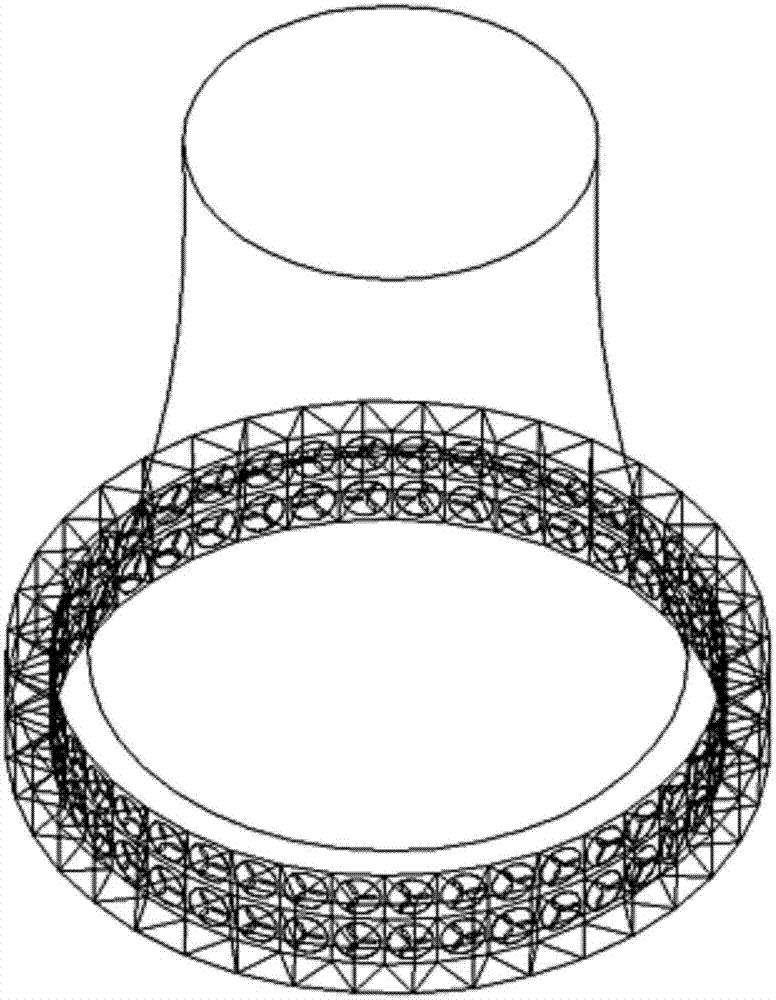

[0031] figure 2 — Figure 5 The shown mixed ventilation direct air cooling system vertically arranged outside the air-cooled condenser tower includes a hyperbolic air-cooled tower 1 , dozens of air-cooled condenser units 2 arranged vertically and circumferentially at the air inlet of the air-cooled tower, and an axial flow fan 3 . The air-cooled condenser is divided into 6-8 cooling fan-shaped areas, which are arranged vertically and circumferentially on the base of the tower base. Each air-cooled condenser unit 2 includes two groups of finned tube bundles, and louvers are installed at the air inlet; the upper part of each condenser unit is connected to the steam distribution pipe 6, and the lower part is connected to the condensate tank; the end of the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com