Coupled Ceramic Capacitors with Composite Electrodes

A technology of ceramic capacitors and composite electrodes, applied in capacitors, fixed capacitors, fixed capacitor electrodes, etc., can solve problems such as electric field distortion of silver film electrodes, and achieve the effect of solving serious distortion and reducing electric field intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

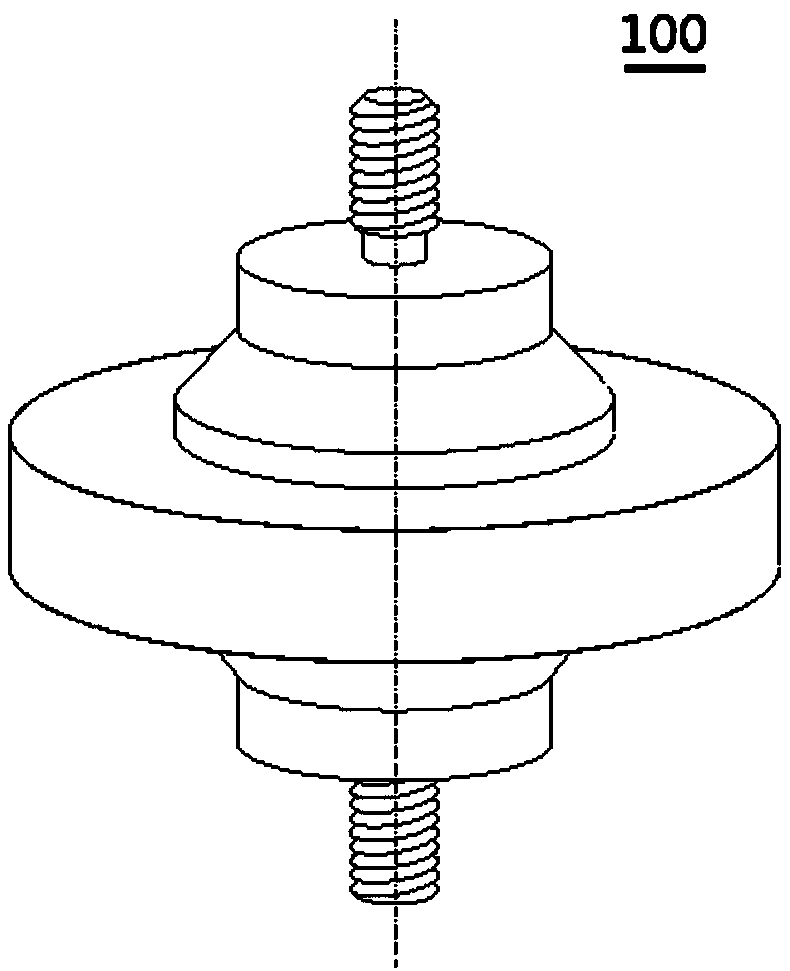

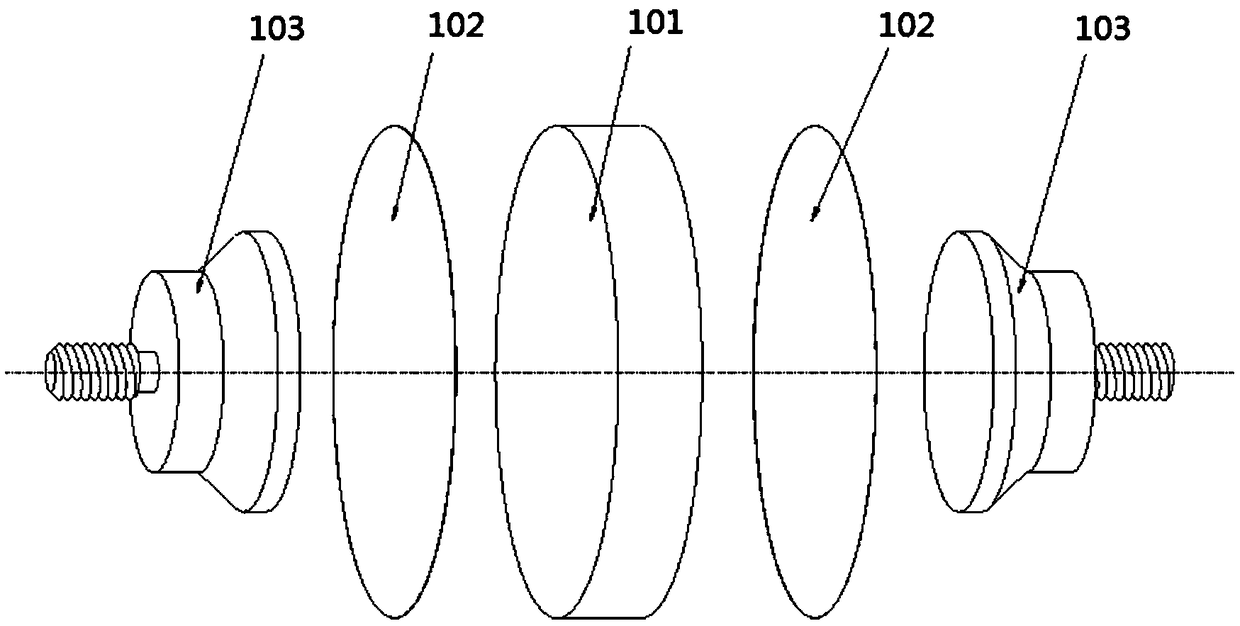

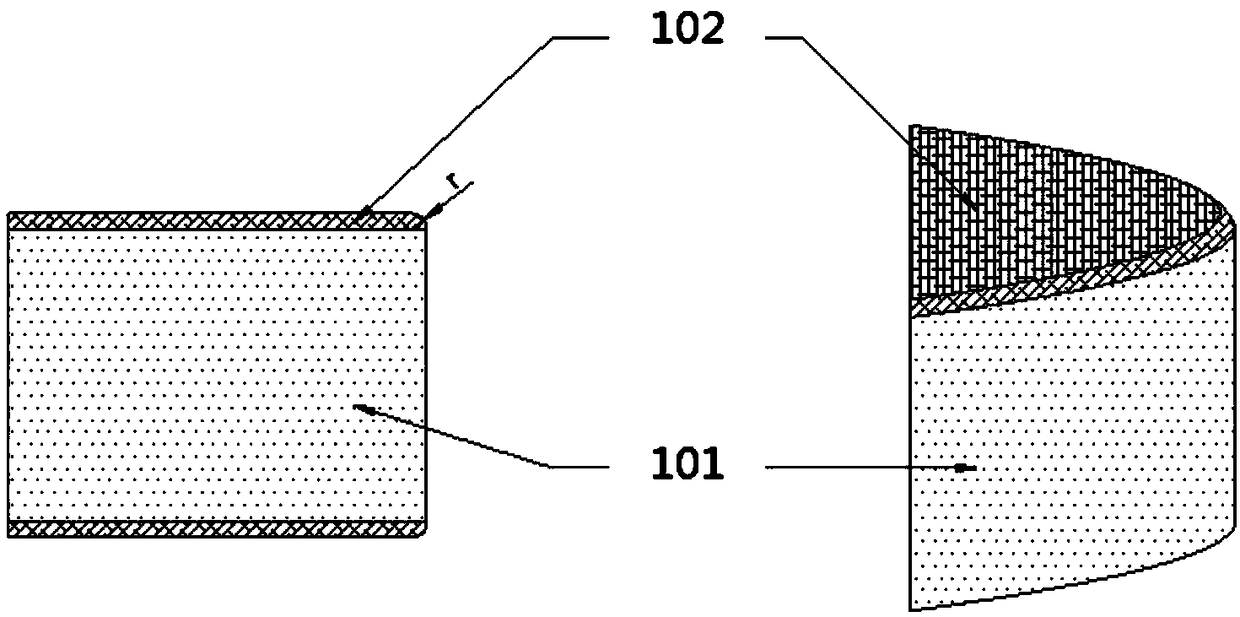

[0046] The present invention provides a coupling ceramic capacitor 300 with a composite electrode, comprising a ceramic medium 301 formed into a flat cylinder and silver film electrodes 302 covering the cylindrical surfaces at both ends of the ceramic medium 301, wherein the edge curvature of the silver film electrode The radius is r, and the ceramic capacitor further includes: a copper electrode 303 covering the outer side of the silver film electrode for covering the edge of the silver film electrode to reduce the electric field intensity at the edge of the silver film electrode. In this case, the copper electrode 303 is combined with the silver film electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com