Method of preparing inorganic polymer poly(iron silicate) flocculating agent from secondary copper slag

A technology of inorganic polymers and polysilicate iron, applied in the field of solid waste utilization research, to achieve the effect of increasing the added value of utilization, good social and economic benefits, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

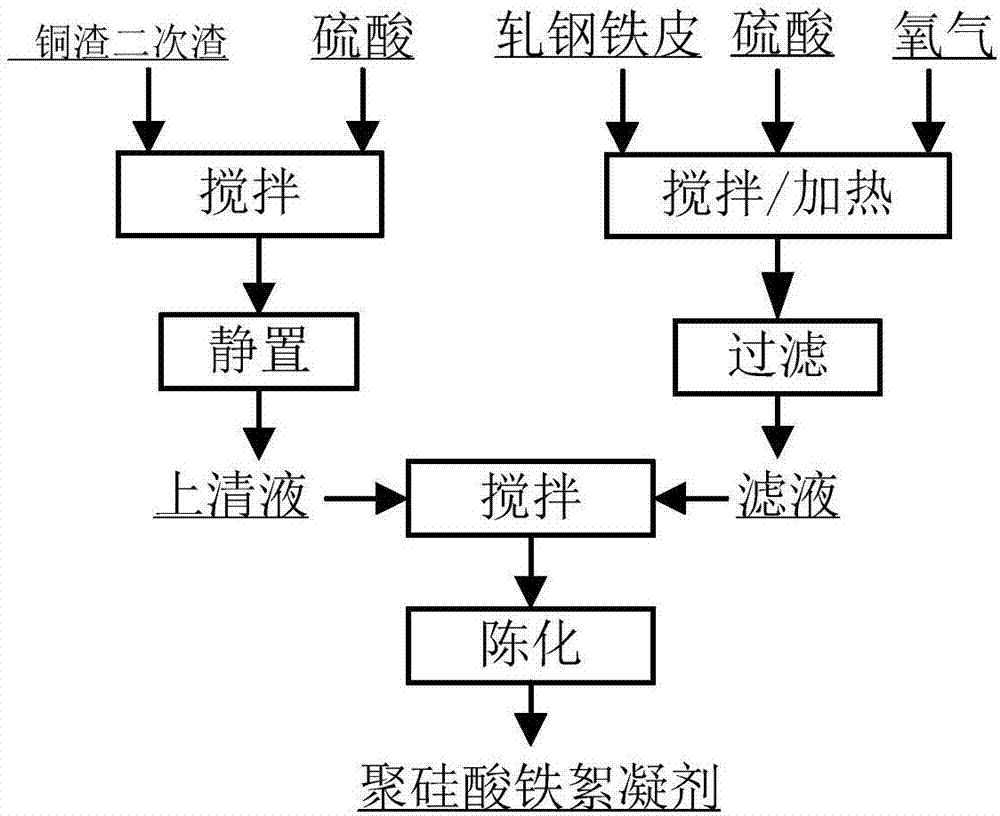

[0033] refer to figure 1 , the present embodiment prepares the inorganic polymer polysilicate iron flocculant according to the following steps:

[0034] Step (1): Add copper slag secondary slag to a concentration of 3m o In the l / L sulfuric acid solution, the mass ratio of copper slag secondary slag and sulfuric acid solution is 1:5. After stirring the copper slag secondary slag and sulfuric acid mixed solution at room temperature for 2 hours, let it stand for 1 hour, and take the supernatant , adding water to adjust the pH to 1.5 to obtain a polysilicic acid solution.

[0035] Step (2): After crushing the rolled steel sheet to less than 1mm in the crushing device, place it in a container with a stirring device and add an industrial sulfuric acid solution with a concentration of 8mol / L, wherein the mass ratio of the rolled steel sheet to the sulfuric acid solution is The ratio is 1:4; Oxygen is passed through and the mixed solution of rolled steel sheet and sulfuric acid is ...

Embodiment 2

[0039] refer to figure 1 , the present embodiment prepares the inorganic polymer polysilicate iron flocculant according to the following steps:

[0040] Step (1): Add the secondary slag of copper slag to the sulfuric acid solution with a concentration of 2mol / L, the mass ratio of the secondary slag of copper slag and the sulfuric acid solution is 1:7, stir the secondary slag of copper slag and sulfuric acid at room temperature After mixing the solution for 2 hours, let it stand for 2 hours, take the supernatant, add water to adjust the pH value to 1, and obtain a polysilicic acid solution.

[0041]Step (2): After crushing the rolled steel sheet to less than 1mm in the crushing device, place it in a container with a stirring device and add an industrial sulfuric acid solution with a concentration of 8mol / L, wherein the mass ratio of the rolled steel sheet to the sulfuric acid solution is The ratio is 1:4; the mixed solution of rolled steel sheet and sulfuric acid is stirred by...

Embodiment 3

[0045] refer to figure 1 , the present embodiment prepares the inorganic polymer polysilicate iron flocculant according to the following steps:

[0046] Step (1): Add the copper slag secondary slag to the sulfuric acid solution with a concentration of 3mol / L, the mass ratio of the copper slag secondary slag and the sulfuric acid solution is 1:5, stir the copper slag secondary slag and sulfuric acid solution at room temperature After mixing the solution for 2 hours, let it stand for 3 hours, take the supernatant, add water to adjust the pH value to 2, and obtain a polysilicic acid solution.

[0047] Step (2): After crushing the rolled steel sheet to less than 1mm in the crushing device, place it in a container with a stirring device and add an industrial sulfuric acid solution with a concentration of 8mol / L, wherein the mass ratio of the rolled steel sheet to the sulfuric acid solution is The ratio is 1:4; Oxygen is introduced and the mixed solution of rolled steel sheet and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com