Biologically-active porous coarse-aggregate ecological bank-protecting matrix engineering material

A technology of ecological revetment and engineering materials, applied in sea area engineering, water conservancy engineering, coastline protection, etc., can solve the problems of lack of aquatic plants in wetlands, plant protection, groundwater resources cannot be effectively replenished, and water ecological environment damage, etc. Achieve the effect of improving the self-purification ability of water body, good vegetation and water permeability, and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

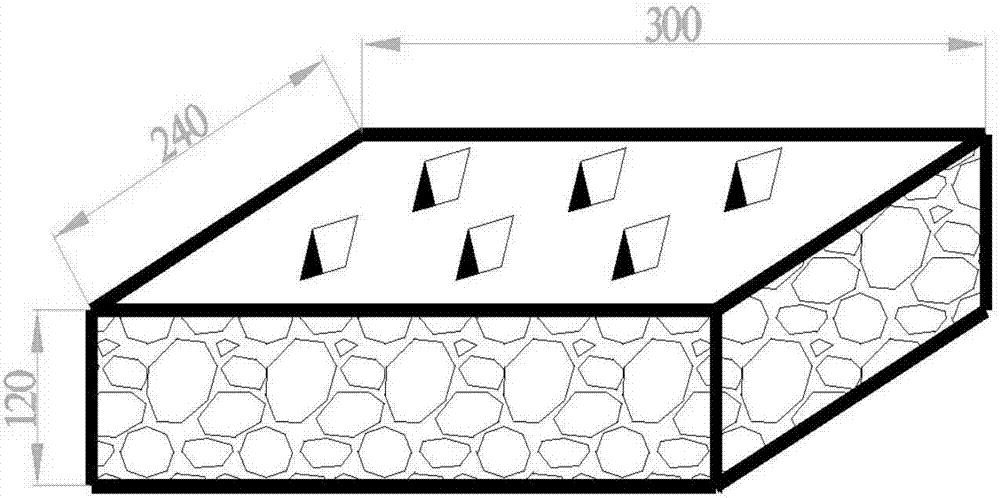

[0033] Embodiment 1 A kind of bioactive porous coarse aggregate ecological revetment matrix engineering material

[0034] 1. Composition

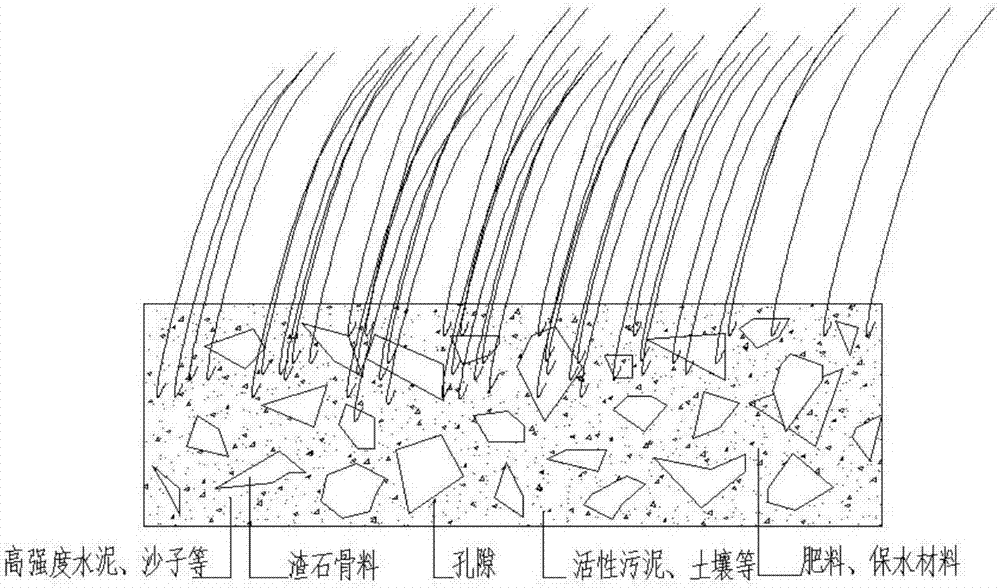

[0035] Including coarse aggregate, bonding material and filling material.

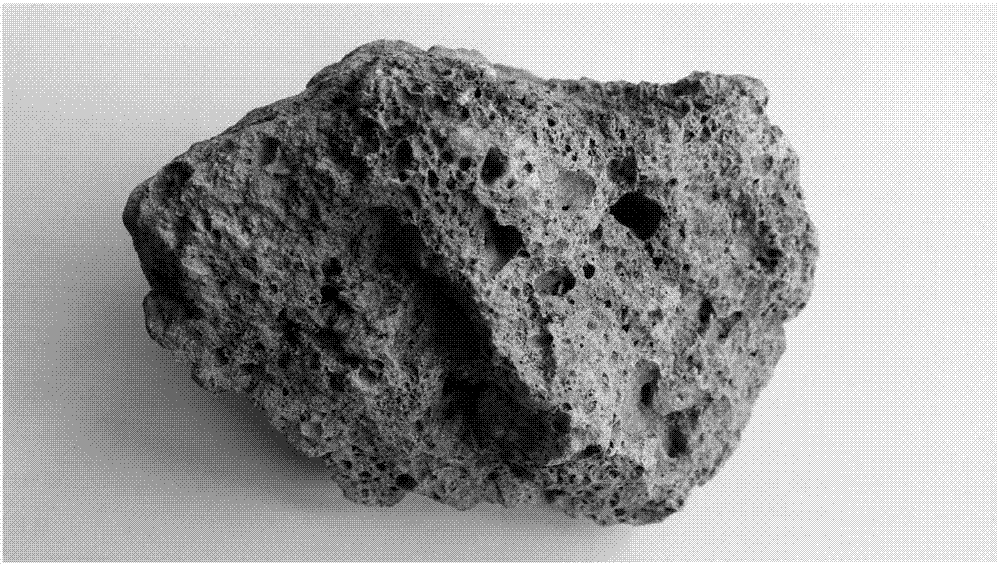

[0036] Coarse aggregate is waste slag, which is a melt with calcium silicate and calcium aluminate as main components, and is a large-pore active material formed after water quenching and rapid cooling. The porosity reaches 10%-15%, and the average pore diameter is 2.5mm. After crushing, sieving and grading, a diameter of 5-15cm is selected for use. It has vegetation and water permeability. The bonding material is a mixture of C60 and above high-strength cement, sand, admixtures and binders; the filling material is a mixture of soil, activated sludge, water-retaining agent and fertilizer.

[0037] Among them: coarse aggregate and bonding material are charged according to the following weight percentages: waste slag (such as figure 1 ), high-strength cement, sand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com