R-t-b based permanent magnet

一种永久磁铁、R-T-B的技术,应用在磁性材料、磁性物体、炉子类型等方向,能够解决供给不稳定、资源稀少、昂贵等问题,达到高矫顽力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0061] A first embodiment of the present invention relates to an R-T-B based sintered magnet which is a type of R-T-B based permanent magnet.

[0062]

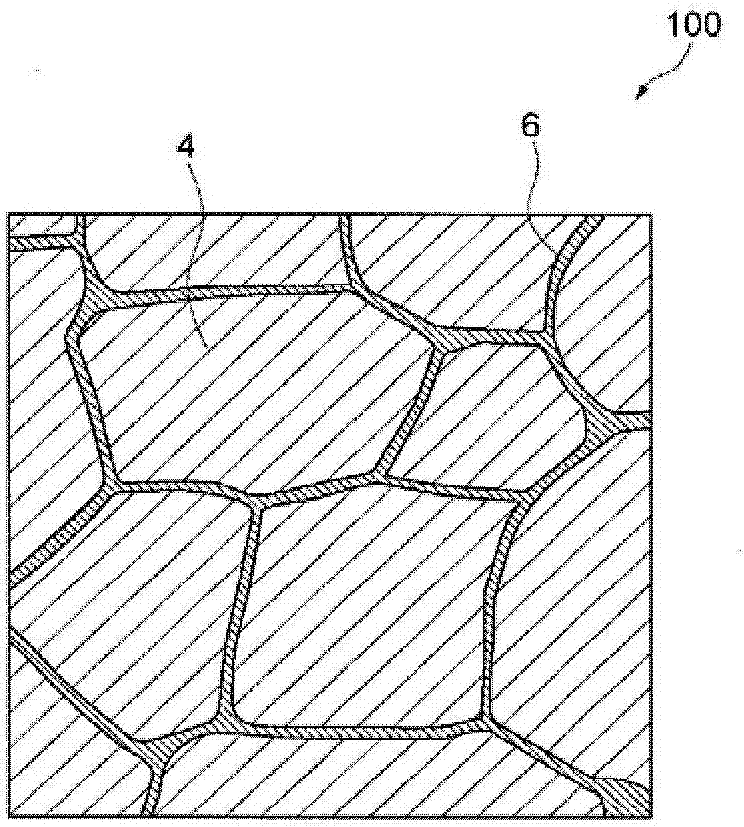

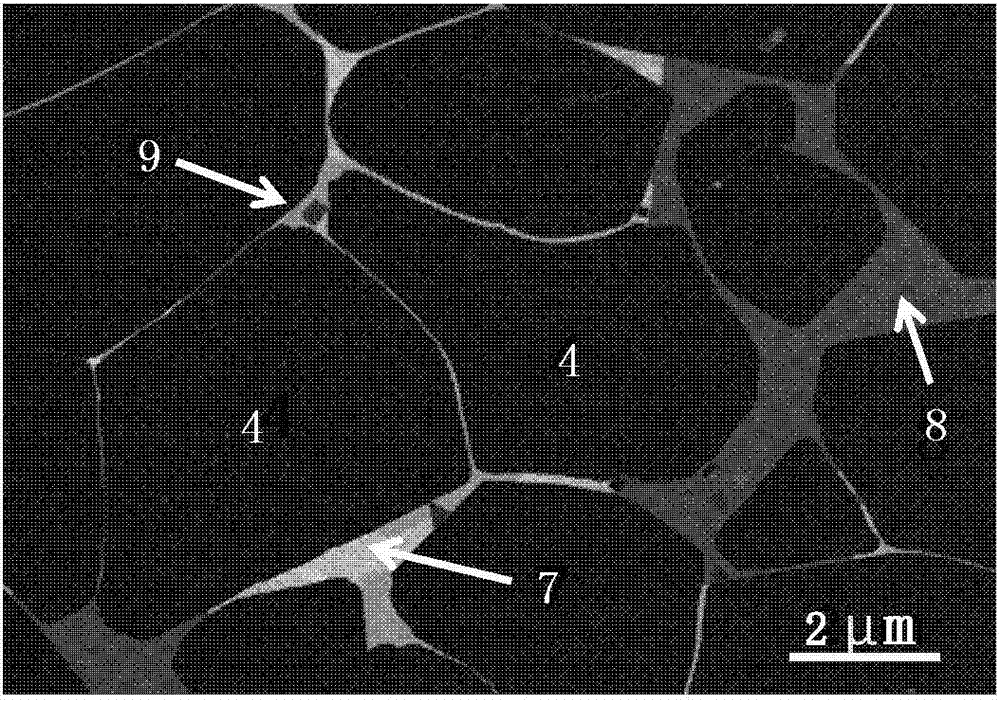

[0063] The R-T-B based sintered magnet according to the first embodiment of the present invention will be described. Such as figure 1 As shown, the R-T-B system sintered magnet 100 according to this embodiment has R 2 T 14 The main phase particles 4 composed of the type B compound and the grain boundaries 6 existing between the main phase particles 4 .

[0064] The main phase particles contained in the R-T-B based sintered magnet according to this embodiment are composed of R 2 T 14 Type B compound constitutes, wherein, the R 2 T 14 Compounds of type B have R 2 T 14 A crystal structure composed of B-type tetragonal crystals.

[0065] R represents at least one kind of rare earth element. The rare earth elements refer to Sc, Y, and lanthanide elements belonging to the third group of the long-period periodic table. A...

no. 2 approach

[0135] The second embodiment of the present invention relates to an R-T-B permanent magnet produced by hot working. The second embodiment is the same as the first embodiment in the points not described below. In addition, it is appropriate to re-read the part described as "sintering" in the first embodiment.

[0136]

[0137] The method of manufacturing the R-T-B based permanent magnet according to this embodiment has the following steps.

[0138] (a) Melting and quenching process of melting the raw material metal and quenching the obtained molten metal to obtain a thin strip

[0139] (b) Pulverization process of pulverizing ribbons to obtain flaky raw material powder

[0140] (c) Cold forming process of cold forming pulverized raw material powder

[0141] (d) Preliminary heating process for preheating cold molded body

[0142] (e) Thermoforming process of thermoforming a preheated cold-formed body

[0143] (f) A thermoplastic working step of plastically deforming a therm...

experiment example 1~7

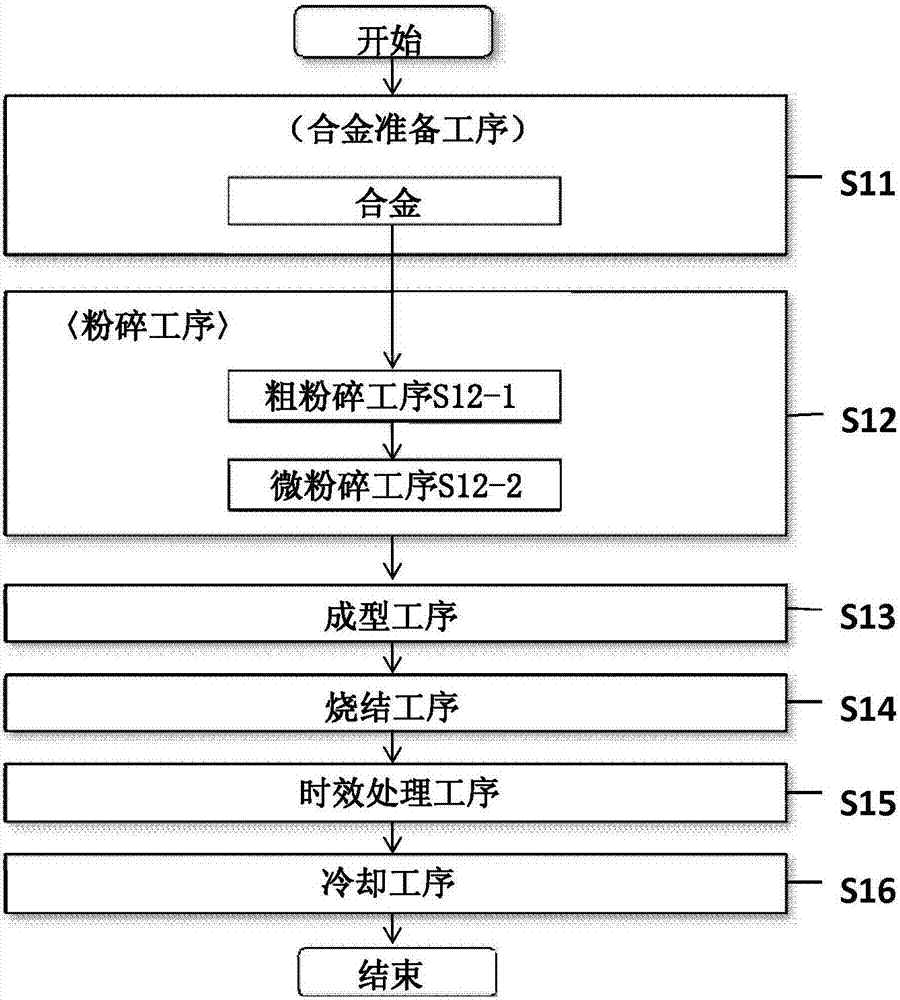

[0170] First, a raw material alloy is prepared. Raw materials were blended so as to obtain an R-T-B based sintered magnet having the composition shown in Table 1, these raw materials were melted, and then cast by a sheet continuous casting method to obtain a flaky raw material alloy. The amount of carbon in the raw material is adjusted using graphite, and by considering the amount of carbon mixed in from the grinding aid during fine grinding, the amount expected to be increased by the grinding aid is subtracted from the charge composition to obtain the final composition of the R-T-B sintered magnet The raw material alloys were prepared so as to have the compositions shown in Table 1.

[0171] Next, each of these raw material alloys was subjected to a hydrogen pulverization treatment (coarse pulverization) of dehydrogenation in an Ar atmosphere at 400° C. for 1 hour after each of these raw material alloys was allowed to absorb hydrogen at room temperature.

[0172] In addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com