Vapor chamber based on flat-plate loop heat pipe

A technology of soaking plate and heat pipe, which is used in circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as increasing flow length, and achieve the effects of small flow resistance, improved heat transfer capacity, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

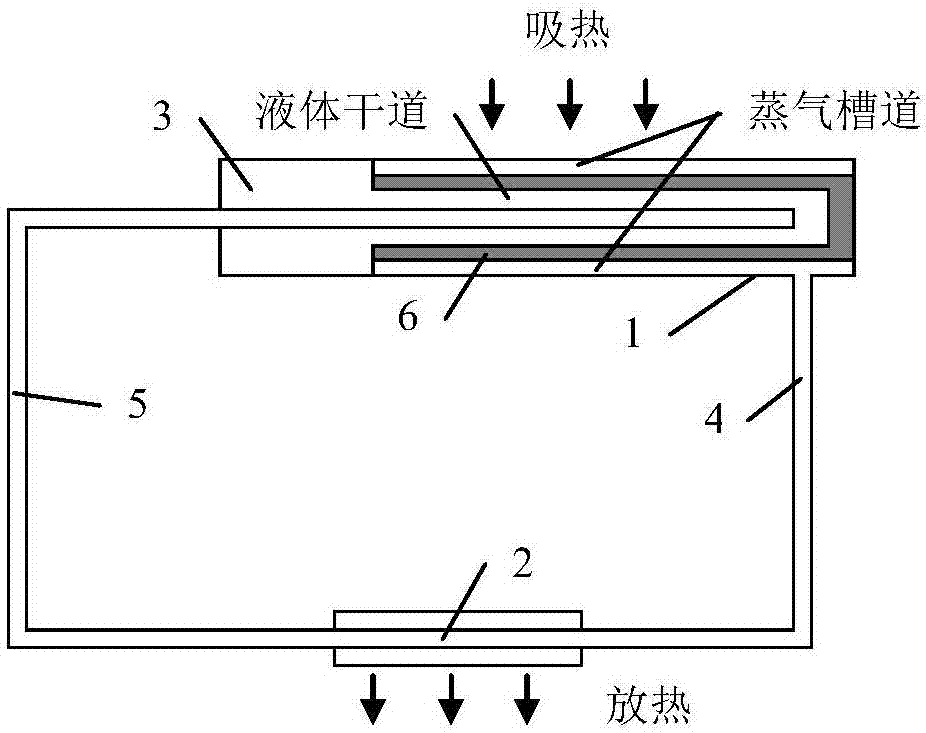

[0026] Example 1: Thermal conduction vapor chamber

[0027] Such as Figure 4-Figure 5 As shown, the flat loop heat pipe composed of the evaporator, the liquid reservoir and the gas / liquid pipeline is pre-embedded in the aluminum alloy heat spreader by gluing or welding to form a vapor chamber based on the flat loop heat pipe. The vapor chamber is installed in close contact with the circuit board to be dissipated, so that the evaporator of the flat-plate loop heat pipe is arranged in the area where the vapor chamber and the largest heat source of the circuit board (that is, the position with the largest heat generation of the circuit board) are attached, and the evaporator The side with the steam channel fits the largest heat source. The evaporator can be pre-buried in the aluminum alloy heating plate, or only fixed in the aluminum alloy heating plate, and the evaporator is exposed and directly attached to the largest heat source. The liquid reservoir of the flat-plate loop ...

Embodiment 2

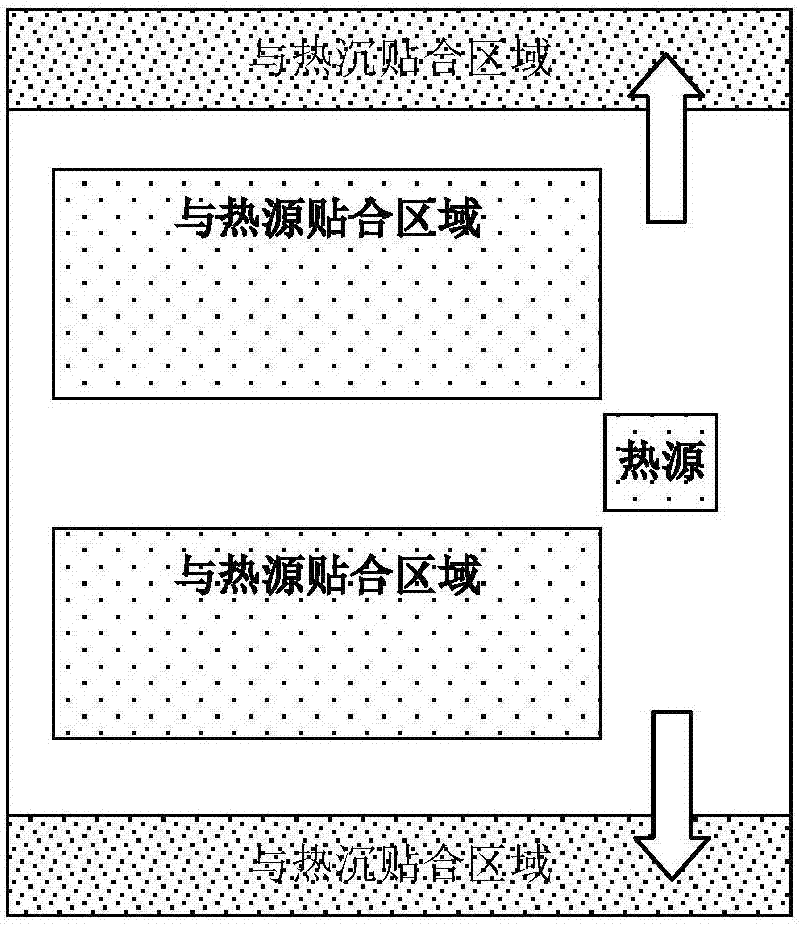

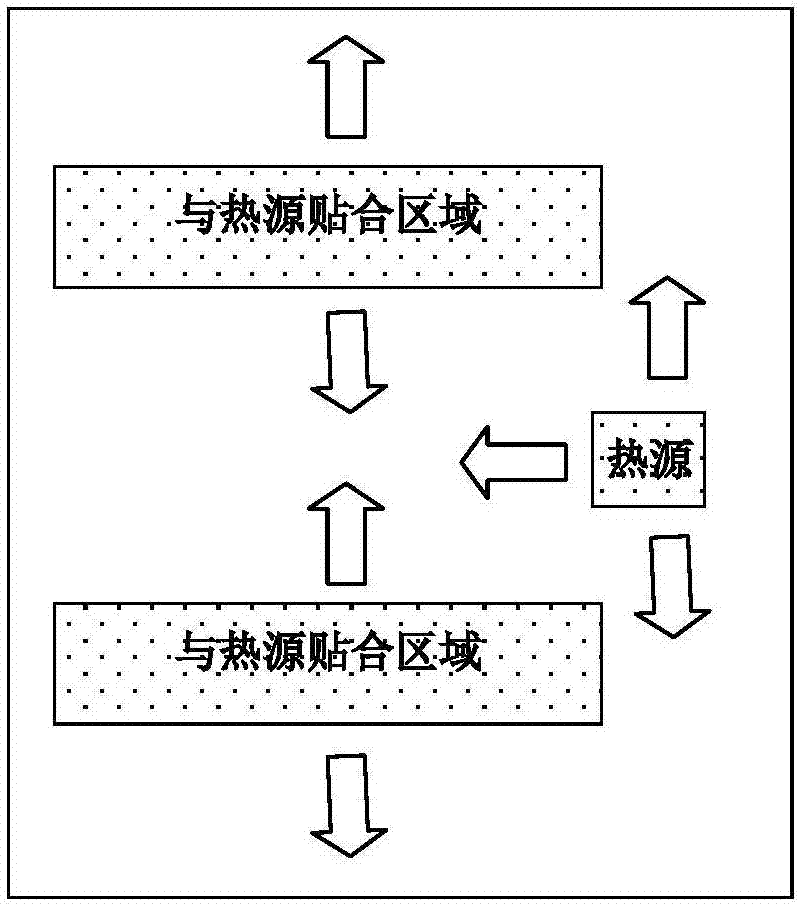

[0029] Example 2: Expansion vapor chamber

[0030] The main difference from the thermal conduction vapor chamber is that, except for the "area that fits with the heat source", the other areas on the vapor chamber that are not in contact with the heat source are regarded as the "area that fits with the heat sink". Therefore, the gas / liquid pipeline is reciprocally arranged between the "area attached to the heat source" and other areas. It works on the same principle as a thermally conductive vapor chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com