High-activity electrode material and modifying method thereof

A kind of electrode material and high activity technology, applied in the field of electrochemistry, can solve the problems of infeasibility of industrial operation, high cost, complicated and difficult methods, etc., and achieve the goal of increasing electrochemical reaction activity, high current density and high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After the graphite felt is formed, it is treated using a phenolic resin as a binder.

[0047] To prepare the dispersion, put 1-200g of water-soluble phenolic resin and 1-100g of activated carbon into 1L of deionized water, and stir for 1-3 hours. A resin dispersion with a concentration gradient of both the phenolic resin and the activated carbon is formed. Cut the graphite felt into a regular square, and cut the side length according to the actual needs, here it is cut to 50*50mm 2 , weigh M0.

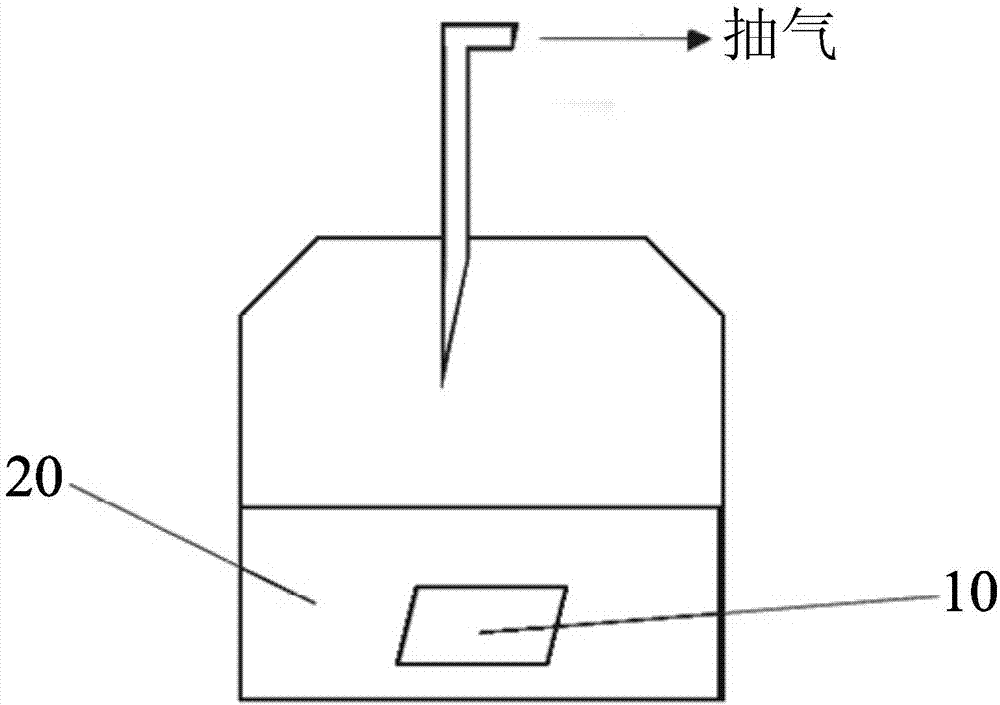

[0048] Such as figure 1 As shown, the activated carbon resin dispersion is poured into a container with high airtightness, the graphite felt 10 is put into the dispersion 20, and the sealing cap is closed.

[0049] Use a vacuum pump to vacuumize the above container, and the processing time is 1-3 hours.

[0050] Take out the treated graphite felt and dry it at 150°C for 2-5 hours.

[0051] The dried graphite felt is treated in a vacuum or an inert gas furnace at 700-900°C f...

Embodiment 2

[0055] In the carbon felt stage, physical methods are used for processing.

[0056] To prepare the water dispersion, put 1-100g of activated carbon into 1L of deionized water and stir on a stirrer for 1-3 hours to form a stable and uniform water dispersion.

[0057] Cut the graphite felt into a regular square, and cut the side length according to the actual needs, here cut to 50*50mm2, weigh M0.

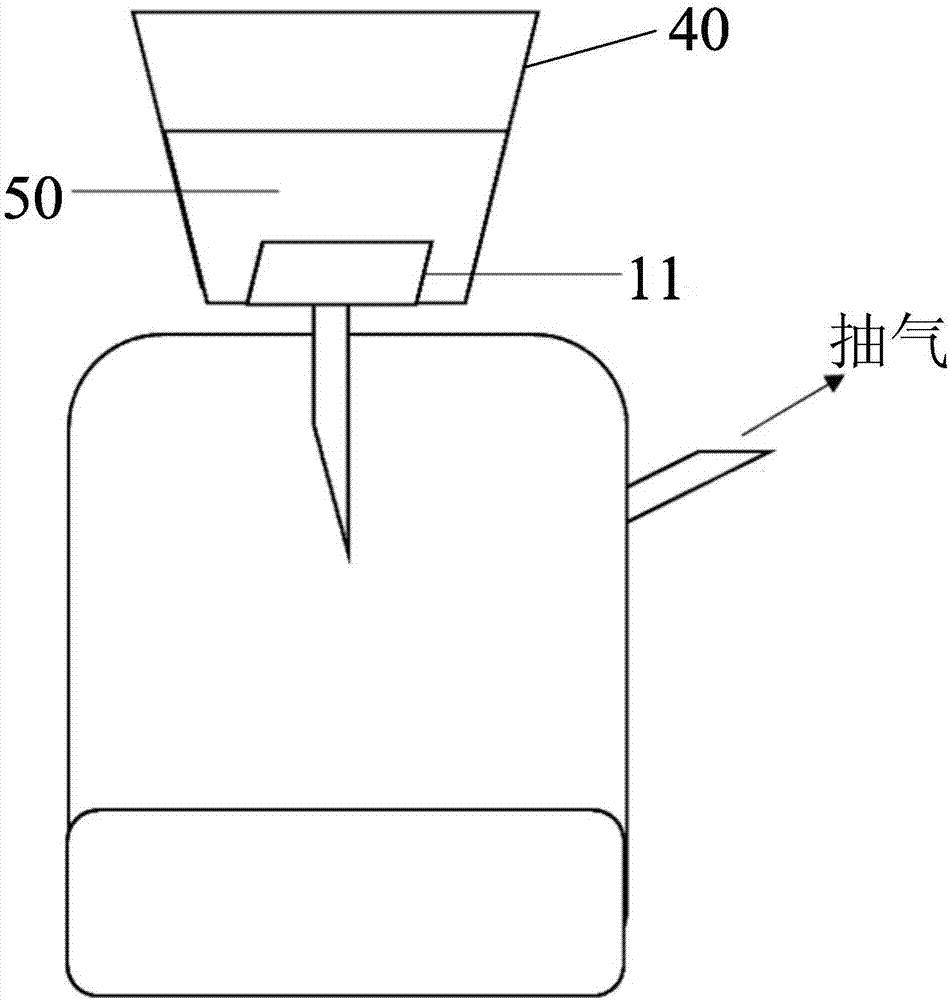

[0058] Such as figure 2 As shown, the filter paper is placed in the Buchner funnel 40, the carbon felt 11 is placed on the filter paper, and the activated carbon water dispersion 50 is poured into the Buchner funnel, and the pouring amount is 100ml.

[0059] Use a vacuum pump to filter until all the liquid in the Buchner funnel is drained.

[0060] The treated carbon felt 11 is graphitized at 1500-3000° C. under vacuum or an inert gas environment.

Embodiment 3

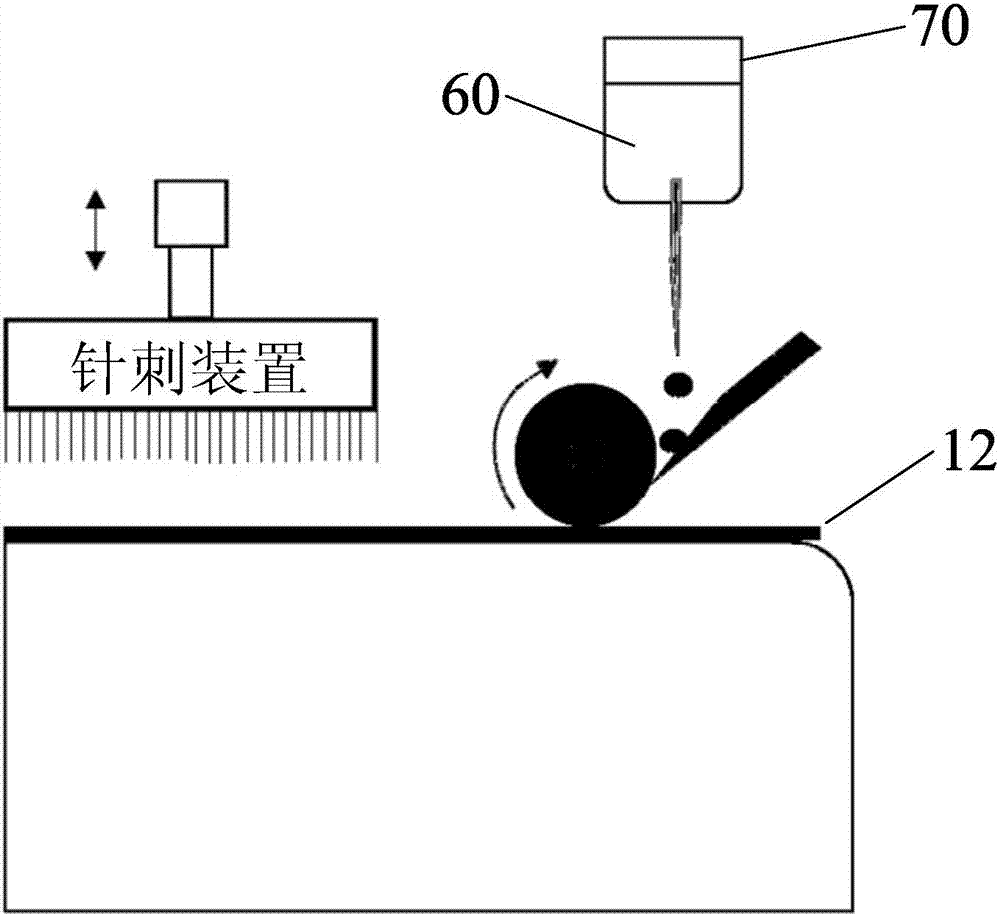

[0062] In the carding stage, physical methods are used for processing.

[0063] To prepare the water dispersion, put 1-100g of activated carbon into 1L of deionized water and stir on a stirrer for 1-3 hours to form a stable and uniform water dispersion.

[0064] Take a certain amount of basic raw materials and put them into an opener for processing. During the processing, slowly add the activated carbon water dispersion in the above steps. The mass ratio of the basic raw material and the activated carbon water dispersion is controlled between 10:1-1:1.

[0065] The treated fiber material is needle-punched, carbonized and graphitized to obtain modified graphite felt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com