Method for dry cleaning of waste plastic by using gas-solid fluidized bed

A waste plastic, dry cleaning technology, used in plastic recycling, recycling technology and other directions, can solve the problems of difficult to remove strong sticky grease on the surface, adapt to a single variety, poor cleaning effect, etc., to achieve strong physical adsorption capacity and good effect. , Reduce the effect of capillary adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

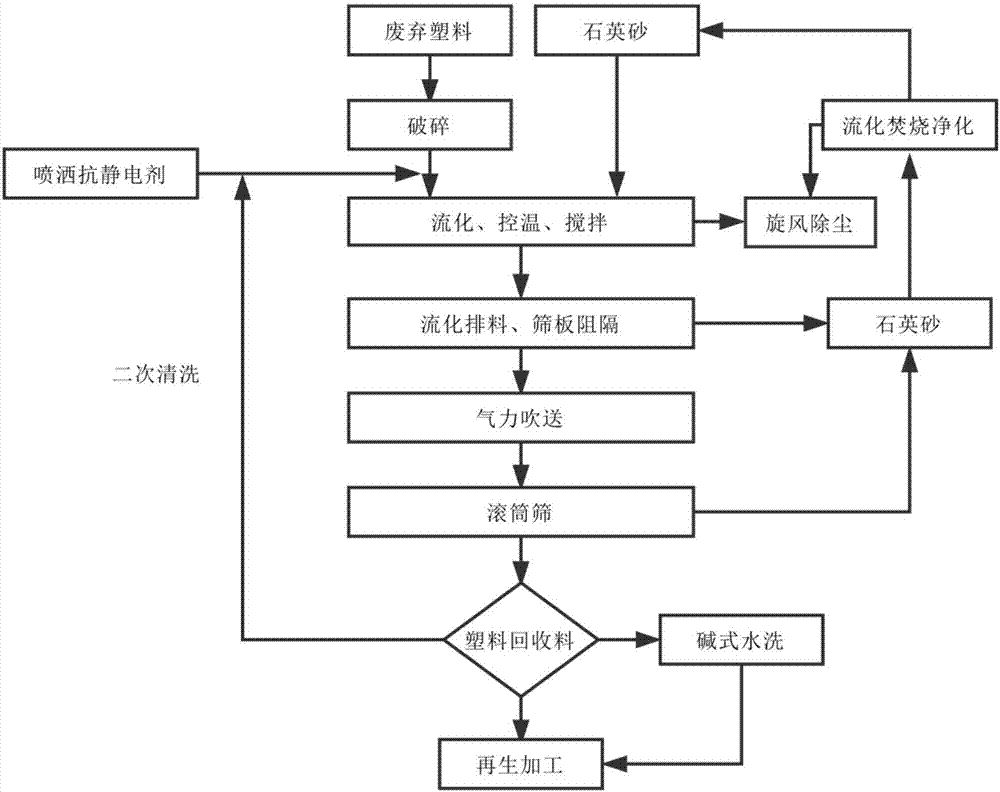

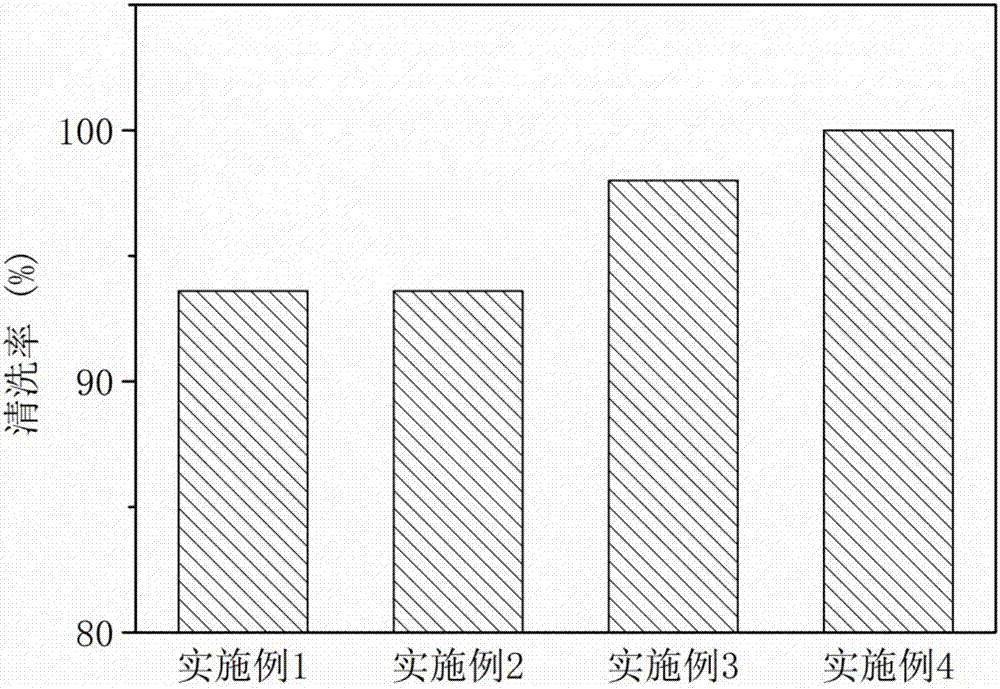

[0025] according to figure 1 The process uses waste plastics sorted from municipal waste as raw materials and puts them into a shear crusher to reduce the size of waste plastics to 10-30 mm. Add water-washed quartz sand with a particle size of 0.3-0.5 mm to the fluidized bed equipment with a stirring device, so that the static height of the cleaning medium in the bed reaches 55 mm. The crushed waste plastics are added into the fluidized bed, and an antistatic agent is sprayed on the surface of the waste plastics. The ratio of crushed waste plastics to quartz sand particles is 1:50, and the amount of antistatic agent is 1 / 100 of the mass of waste plastics. Turn on the high-pressure fan to make the superficial gas velocity reach 0.25 m / s, turn on the heating temperature control system to keep the temperature at 40°C, turn on the stirring device to keep the speed at 90 rpm (at this time, the pressure drop of the fluidized bed layer is 800Pa) , and maintain the cleaning time for...

Embodiment 2

[0027] according to figure 1 The process uses waste plastics sorted from municipal waste as raw materials and puts them into a shear crusher to reduce the size of waste plastics to 10-30 mm. Add water-washed quartz sand with a particle size of 0.3-0.5 mm to the fluidized bed equipment with a stirring device, so that the static height of the cleaning medium in the bed reaches 25 mm. Put the crushed waste plastics into the fluidized bed equipment, and spray the antistatic agent on the surface of the waste plastics. The ratio of crushed waste plastics to quartz sand is 1:20, and the amount of antistatic agent is 1 / 100 of the mass of waste plastics. Turn on the high-pressure fan to make the superficial gas velocity reach 0.17 m / s, keep the air flow at room temperature 20°C, turn on the stirring device to keep the speed at 90 rpm (at this time, the pressure drop of the fluidized bed layer is 330Pa), and maintain the cleaning time 10 minutes. During cleaning, the cyclone separato...

Embodiment 3

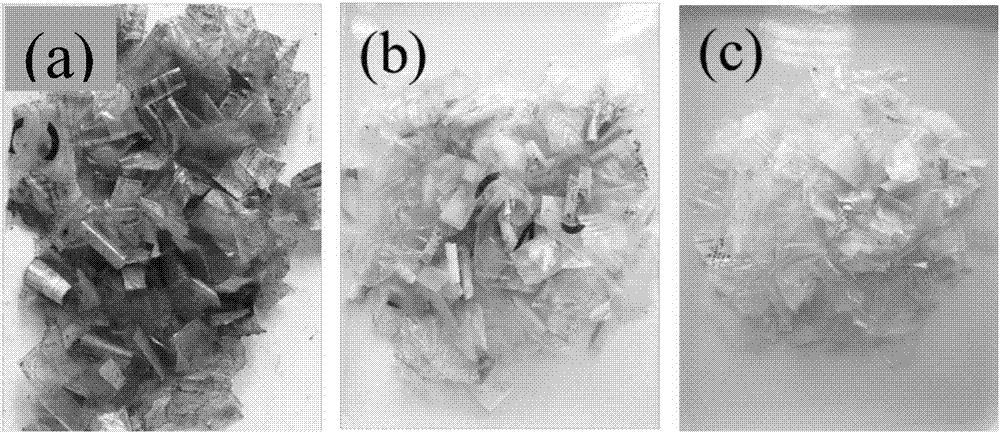

[0029] according to figure 1 The process uses waste plastics sorted from municipal solid waste as raw materials and puts them into a shear crusher to reduce the size of waste plastics to 10-30 mm. The broken waste plastics were dry-cleaned twice, and the operating conditions were the same as in Example 2. In this embodiment, the overall cleaning rate of waste plastics is 98.0%. The obtained plastic sheets and films have smooth surfaces without visible particles and grease impurities. The cleaning effect is equivalent to that of alkaline water washing. See figure 2 , image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com