Method for preparing large-pore-volume hydrated silica by pH (potential of hydrogen) swing method

A silicon dioxide and hydration technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of unreasonable pore volume and dispersion, unsatisfactory performance, complicated preparation methods, etc., and achieve good dispersion and large pore volume , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

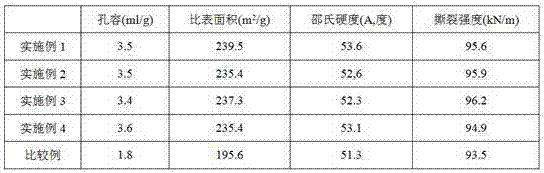

Examples

Embodiment 1

[0019] (1) Add 2L of sodium silicate solution with a mass fraction of 7% and 40g of sodium citrate to the reaction kettle and stir evenly, oil bath to 80℃;

[0020] (2) Adjust the pH to 9-10 with ammonia water and stabilize for 20 minutes;

[0021] (3) Add a 5% sulfuric acid solution with a mass fraction of 0.5L / hour until the pH value is 3-4 and stabilize for 10 minutes;

[0022] (4) Repeat the above steps (2) and (3) three times;

[0023] (5) Wash and dry the precipitate to obtain hydrated silica.

Embodiment 2

[0025] (1) Add 2L of 10% sodium silicate solution and 60g of sodium toluene sulfonate into the reaction kettle and stir evenly, oil bath to 90℃;

[0026] (2) Adjust the pH to 9-10 with ammonia water and stabilize for 20 minutes;

[0027] (3) Add a 10% sulfuric acid solution with a mass fraction of 10% at a rate of 0.8L / hour to a pH of 3-4, and stabilize for 10 minutes;

[0028] (4) Repeat the above steps (2) and (3) three times;

[0029] (5) Wash and dry the precipitate to obtain hydrated silica.

Embodiment 3

[0031] (1) Add 2L of 8% sodium silicate solution and 50g of sodium toluene sulfonate into the reaction kettle and stir evenly, oil bath to 80℃;

[0032] (2) Adjust the pH to 9-10 with ammonia water and stabilize for 20 minutes;

[0033] (3) Add 8% sulfuric acid solution at a rate of 0.6L / hour to pH 3-4 and stabilize for 10 minutes;

[0034] (4) Repeat the above steps (2) and (3) three times;

[0035] (5) Wash and dry the precipitate to obtain hydrated silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com