Preparation method of graphene/carbon black composite particle

A technology of composite particles and graphene, which is applied in the production of bulk chemicals, etc., can solve the problems of poor dispersion of graphene and carbon black, and achieve the effects of excellent characteristics and performance, low density, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

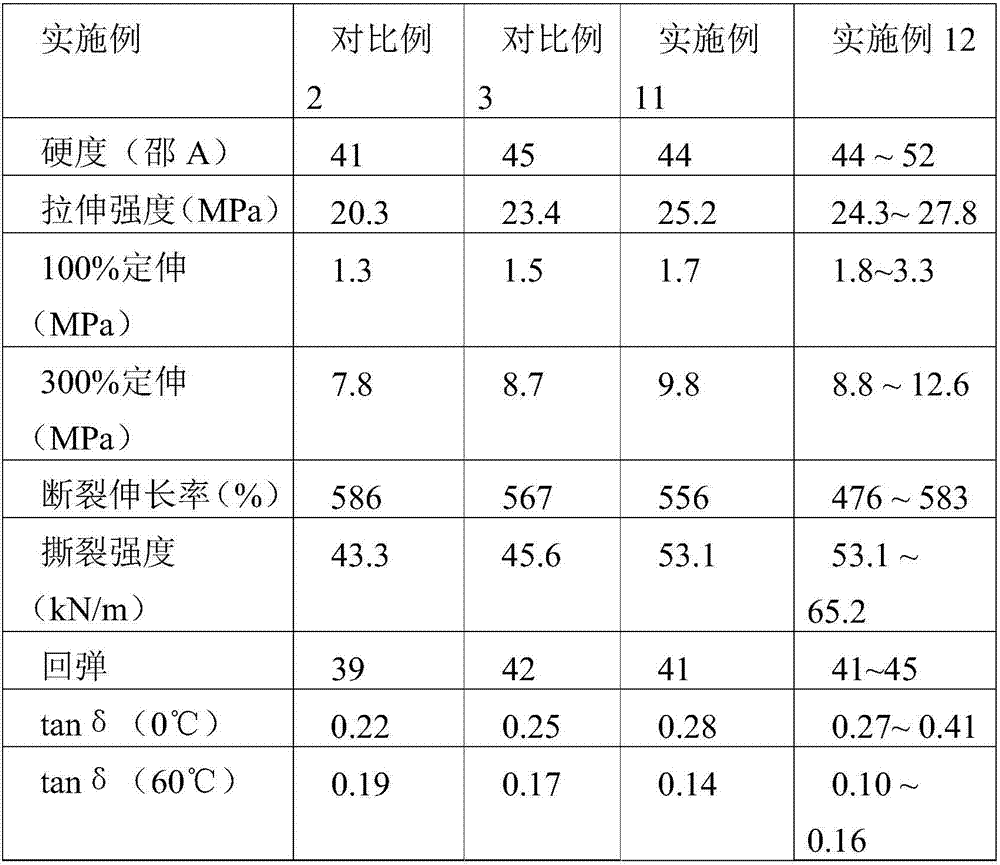

Examples

Embodiment 1

[0020] (1) Mix 1g of graphene oxide with water to obtain a solution of graphene oxide, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 900HZ, the temperature is 25°C, the ultrasonic time is 0.5h, and the obtained concentration is 1mg / ml of graphene oxide solution;

[0021] (2) Add 0.8 g of carbon black powder to the graphene oxide solution, and then perform ultrasonic dispersion to obtain a graphene oxide / carbon black solution. The ultrasonic frequency is 1000HZ, the time is 0.5h, and the temperature is controlled below 50°C. Add 0.05 g of sodium polystyrene sulfonate, and magnetically stir the mixture for 30 min at room temperature;

[0022] (3) Put the obtained graphene oxide / carbon black aqueous solution into a beaker, then add 5 mg of hydroquinone, mix for 30 minutes, then heat the mixed solution at a constant temperature and keep it at 30°C, and react for 8 hours to obtain graphene / carbon black gel;

[0023] (4) the gr...

Embodiment 2

[0027] (1) Mix 2g of graphene oxide with ethanol to obtain a solution of graphene oxide, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 800HZ, the temperature is 30°C, the ultrasonic time is 0.8h, and the obtained concentration is 2mg / ml of graphene oxide ethanol solution;

[0028] (2) 1 g of carbon black powder was added to the graphene oxide ethanol solution, and then ultrasonically dispersed to obtain the graphene oxide / carbon black ethanol solution. The ultrasonic frequency is 800HZ, the time is 0.8h, and the temperature is controlled below 50°C. Then add 0.05g sodium dodecylsulfonate, and the above mixed solution is magnetically stirred at room temperature for 30min;

[0029] (3) Put the ethanol solution of the obtained graphene oxide / carbon black into a beaker, then add 5 mg of sodium borohydride, mix for 30 minutes, then heat the mixed solution to maintain a constant temperature at 30° C., and react for 12 hours to ob...

Embodiment 3

[0034] (1) Mix 2g of graphene oxide with acetone to obtain a solution of graphene oxide, put it in an ultrasonic instrument for further ultrasonic dispersion, the ultrasonic frequency is 600HZ, the temperature is 30°C, the ultrasonic time is 0.8h, and the obtained concentration is 2mg / The graphene oxide acetone solution of ml;

[0035](2) 1g of carbon black powder was added to graphene oxide acetone solution, and then ultrasonically dispersed to obtain graphene oxide / carbon black acetone solution. The ultrasonic frequency is 800HZ, the time is 0.8h, and the temperature is controlled below 50°C. Add 0.05 g of sodium polystyrene sulfonate, and magnetically stir the mixture for 30 min at room temperature;

[0036] (3) Put the acetone solution of graphene oxide / carbon black obtained in a beaker, then add 5 mg of sodium borohydride, mix for 30 minutes, then heat the mixed solution at a constant temperature and keep it at 30° C., and react for 12 hours to obtain graphene / carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com