Multilayer double-side foamed functional fabric and production process thereof

A functional and fabric technology, applied in multi-strand fabric, spray/jet textile material processing, weaving, etc., can solve problems such as functional fiber product development limitations, achieve the effect of unique structure and expand market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

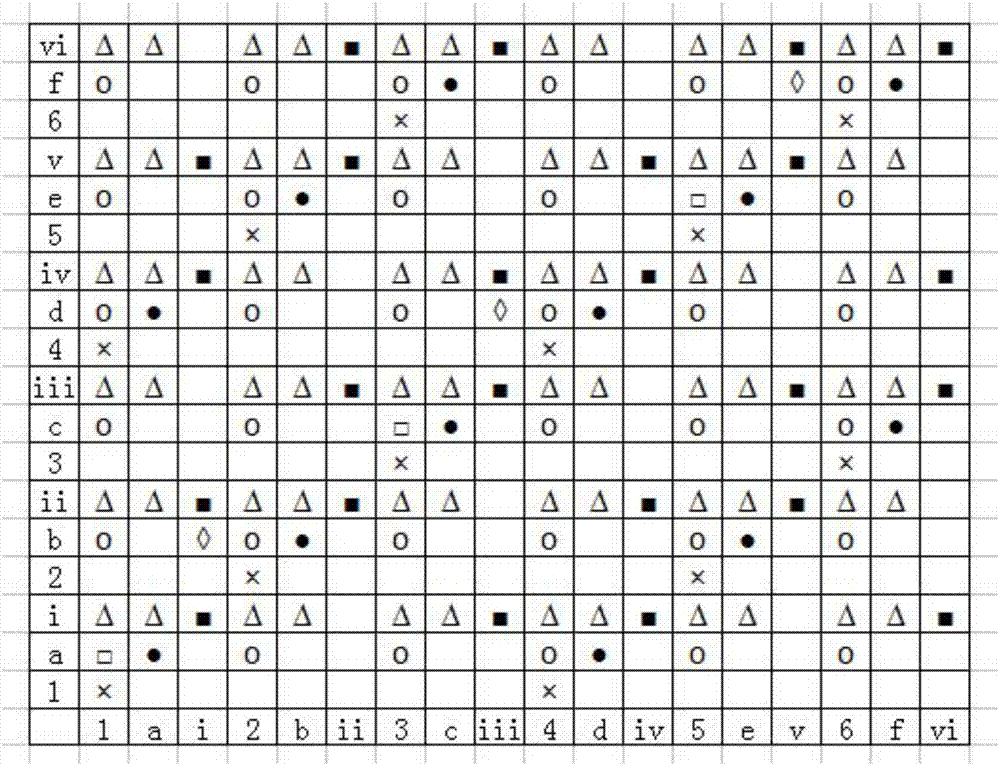

[0045] Such asfigure 1 As shown, the thermal fabric consists of three layers. Surface layer: raw materials are coffee charcoal polyester fiber, colored viscose, polyimide fiber, copper ion modified polyester fiber, middle layer: high-shrinkage polyester fiber filament is used for weft yarn, and high-strength and low-elongation polyester fiber is used for warp yarn Filament, inner layer: raw materials are coffee charcoal polyester fiber, colored viscose, polyimide fiber, copper ion modified polyester fiber. The weft yarn in the middle layer shrinks, causing the surface and inner layers to bulge, forming a crepe shape. This fabric is multi-layered, fluffy, warm, antibacterial, moisture-permeable, breathable, stylish, unique in structure, and can be used on both sides.

[0046] The present invention utilizes the color characteristics of functional fibers to research and develop fancy yarns for fabric production through yarn design, so as to meet the functional requirements of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com