Bidirectional cooling dynamic casting composite ingot casting method and device

A composite ingot and dynamic pouring technology, applied in ingot workshop, foundry workshop, casting equipment, etc., can solve the problem of not considering the combination of steel core and melt, internal quality defects of ingot, etc., to eliminate interface defects, The effect of reducing porosity and stomatal defects and improving the quality of the heart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

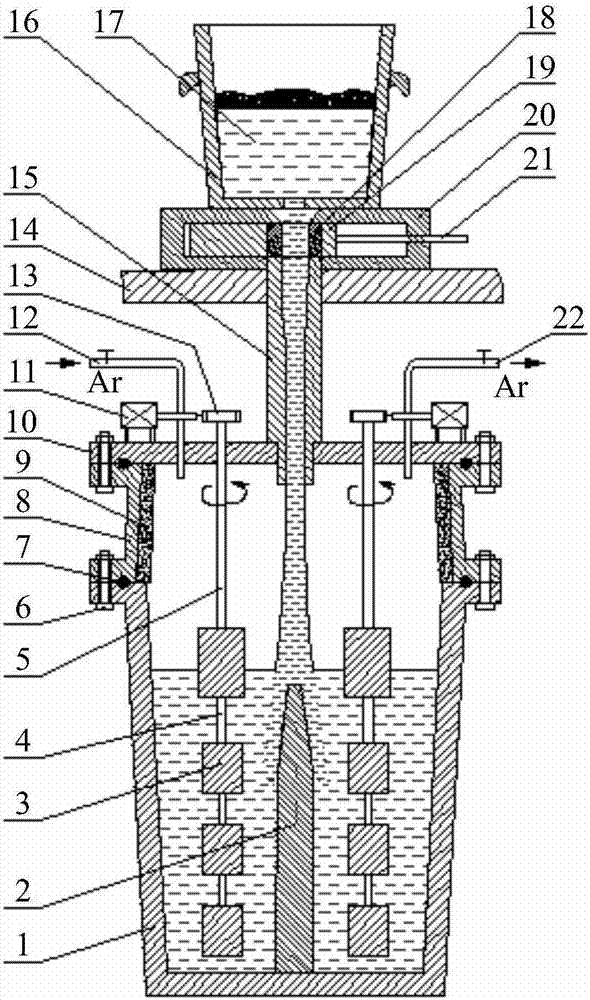

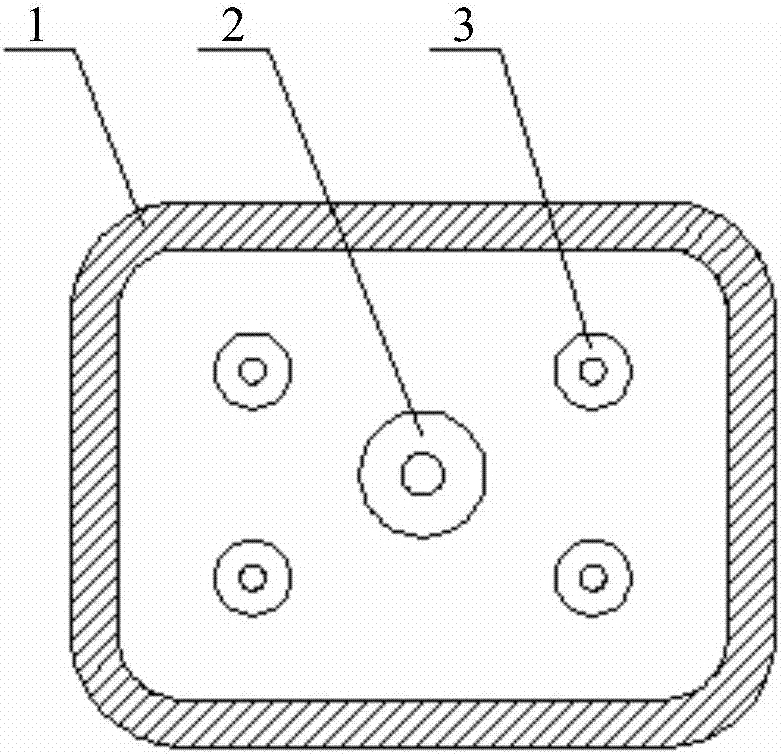

[0057] A Q345 alloy steel ingot with a weight of 145 tons and a size of 2400×2400×3450mm prepared by the above injection method is taken as an example. The specific preparation method is as follows: figure 1 As shown, one forged Q345 bar of φ600×3200mm is selected as the punching core blank 2, 16 forged Q345 bars of φ480×600mm are selected as the tempering core blank 3, and 12 rolled Q345 bars of φ60×240mm are selected. As the connecting rod 4, four Q345 rods of φ80×2000mm are selected as the rotating rod 5, and the surface of the rods is cleaned, degreased, descaled, and dried; The connecting rod 4 of ×240mm connects four φ480×600mm core blanks, and one end thereof is connected with a φ80×2000mm rotating rod 5 to form 4 groups of temperature-regulating core blanks 3 .

[0058] Put the punching core blank 2 and the temperature-adjusting core blank 3 into a conventional drying furnace to preheat to 150°C, keep it warm for 1 hour, and then place the punching core blank 2 in the ...

Embodiment 2

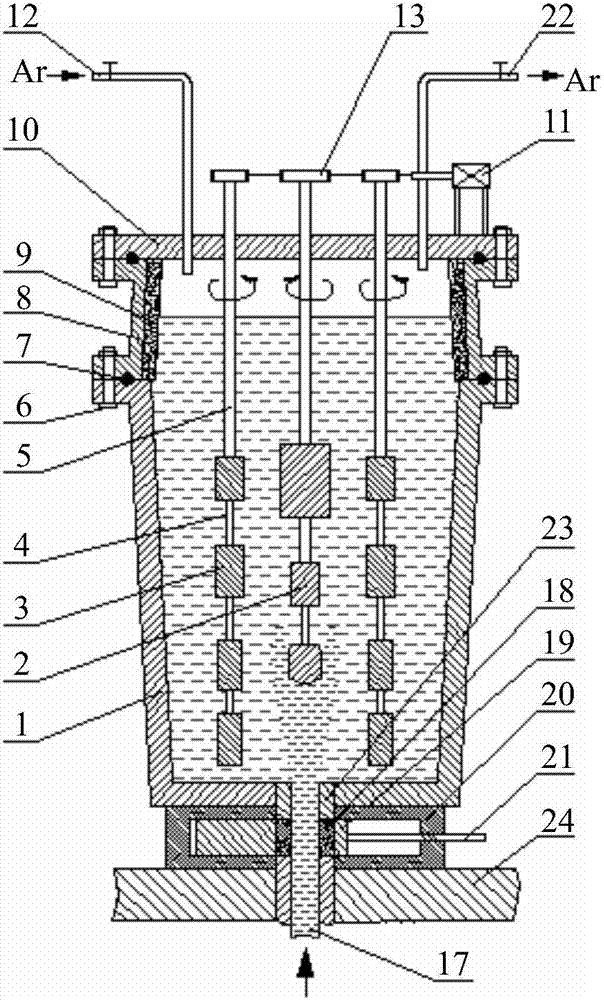

[0067] The following injection method is used to prepare an alloy steel ingot with a weight of 85 tons and a size of 2000×2250×2600mm as an example. The specific preparation method is as follows: figure 2 As shown, 2 forged Q345 bars of φ600×800mm are selected as punching and melting core blanks 2, 16 forged Q345 bars of φ400×400mm are selected as temperature-adjusting core blanks 3, and 12 rolled Q345 bars of φ50×160mm are selected. As the connecting rod 4, four Q345 rods of φ60×1600mm are selected as the rotating rod 5, and the surface of the rods is cleaned, degreased, descaled, and dried; using a conventional electric welding method, one φ50 A connecting rod 4 of ×160mm connects two steel blocks of φ600×800mm, and connects a rotating rod 5 of φ60×1600mm at one end to form a group of punching billets 2, and uses three connecting rods 4 of φ50×160mm to connect the 4 A φ400×400mm steel block 3 is connected at intervals, and one end thereof is connected with a φ60×1600mm rota...

Embodiment 3

[0077] Such as figure 1 with image 3 As shown, the device is the device used in the upper injection method of Example 1, which consists of a casting mold 1, a punching core blank 2, a temperature-adjusting core blank 3, a connecting rod 4, a rotating rod 5, a bolt 6, and an asbestos pad 7 , cap mouth 8, heat insulation plate 9, mold cover 10, motor 11, air intake pipe 12, transmission mechanism 13, pouring platform 14, upper nozzle 15, ladle 16, valve core 18, valve plate 19, valve body 20, valve stem 21. The exhaust pipe 22 is composed of the punching and melting core billet 2, the temperature regulating core billet 3, the connecting rod 4 and the rotating rod 5. The composition of the ingot is the same as that of the cast finished product. The punching and melting core billet 2 and the temperature-adjusting core billet 3 are composed of steel blocks cut to length and connecting rods 4 cut to length and welded together in sections at certain intervals. One end of each grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com