Magnetic Fe3O4 nano-fiber material as well as preparation method thereof and application thereof in catalytic reaction of mimetic peroxidase

A technology of peroxidase and nanofibers, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, fiber chemical characteristics, etc., can solve the problems of difficult preparation of nanofiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

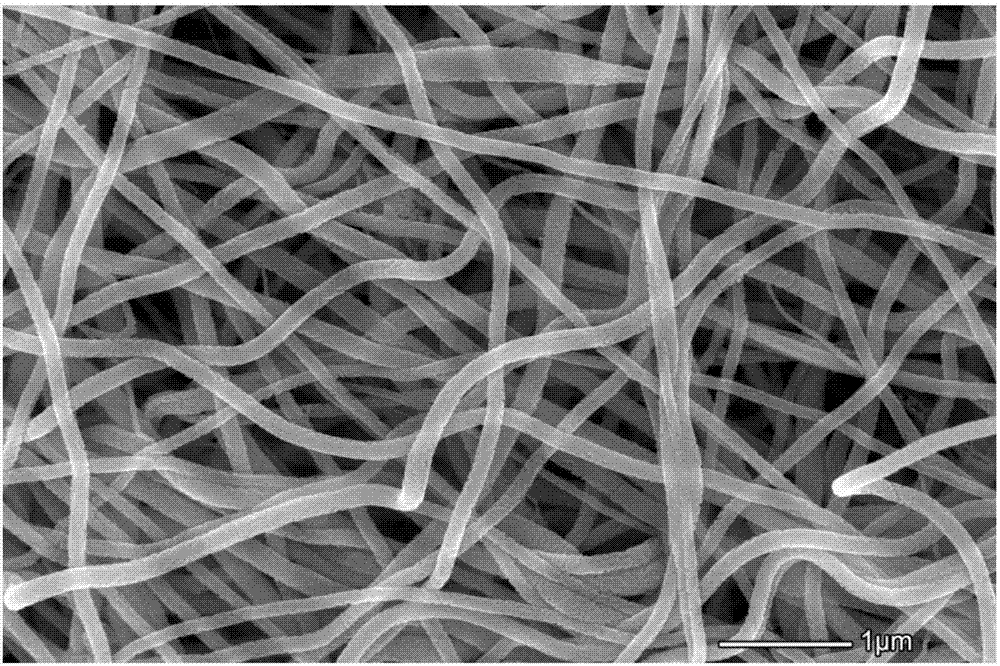

Embodiment 1

[0024] 0.9 g of ferric nitrate and 0.9 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 6 mL of DMF and 6 mL of isopropanol. Stir magnetically at room temperature to obtain a uniform spinning precursor solution. Then, an electrospinning device was used to spin under the conditions of a spinning distance of 20 cm and a spinning voltage of 18 kV to prepare PVP / iron nitrate nanofibers. Then calcined at 450°C for 3 hours in the air to obtain pink Fe 2 o 3 Nanofibers. Fe obtained under this condition 2 o 3 The morphology is fibrous, and the mass of the obtained product is about 50 mg.

Embodiment 2

[0026] 0.9 g of ferric nitrate and 0.4 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 6 mL of DMF and 6 mL of isopropanol. Stir magnetically at room temperature to obtain a uniform spinning precursor solution. Then, an electrospinning device was used to spin under the conditions of a spinning distance of 20 cm and a spinning voltage of 18 kV to prepare PVP / iron nitrate nanofibers. Then calcined at 450°C for 3 hours in the air to obtain pink Fe 2 o 3 Nanofibers. With respect to embodiment 1, the Fe obtained under this condition 2 o 3 The shape of nanofibers is mostly fibrous, and there are a small amount of granular products, and the quality of the obtained product is about 50 mg.

Embodiment 3

[0028] 0.9 g of ferric nitrate and 1.5 g of polyvinylpyrrolidone (PVP) were dissolved in a mixed solution of 6 mL of DMF and 6 mL of isopropanol. Stir magnetically at room temperature to obtain a uniform spinning precursor solution. Then, an electrospinning device was used to spin under the conditions of a spinning distance of 20 cm and a spinning voltage of 18 kV to prepare PVP / iron nitrate nanofibers. Then calcined at 450°C for 3 hours in the air to obtain pink Fe 2 o 3 Nanofibers. Fe obtained under this condition 2 o 3 The appearance of the nanofibers is fibrous, but the diameter is thicker than that of Example 1, and the quality of the obtained product is about 50 mg.

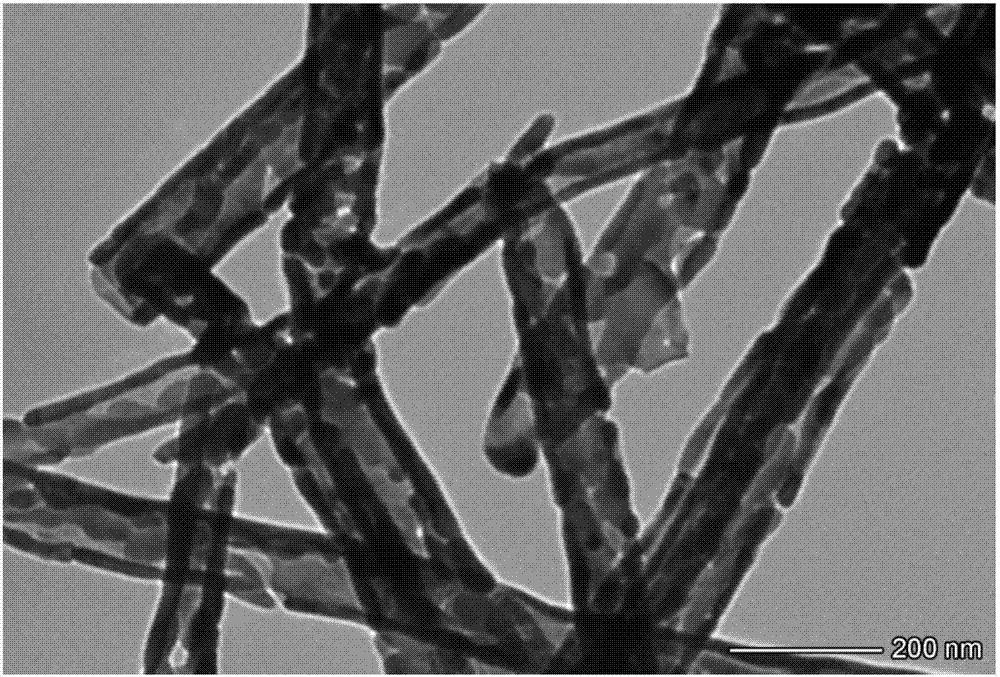

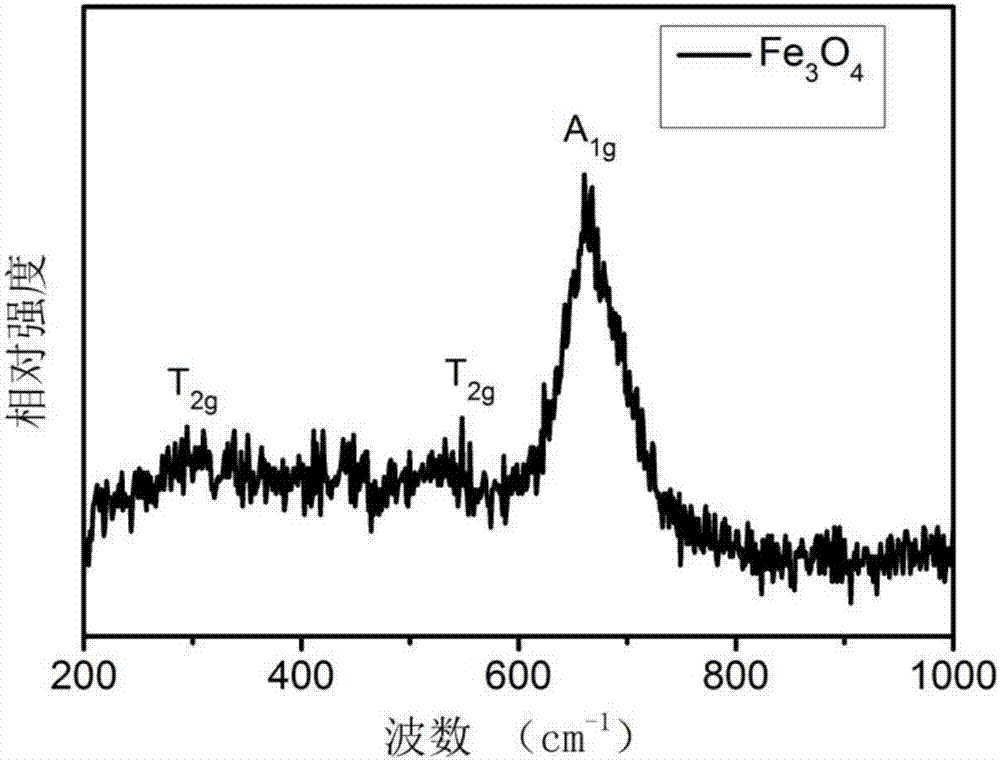

[0029] Preparation of Fe by Polymer Assisted Thermal Reduction in Inert Atmosphere 3 o 4 Nanofibers

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com