Preparation method of black tea fungus pellicle

A technology of kombucha fungus and biofilm, applied in the direction of microorganism-based methods, biochemical equipment and methods, tea extraction, etc., can solve the problems of poor taste, inefficient production, low yield, etc., to promote the formation of biofilm, weaken Inhibitory effect, effect of increasing growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

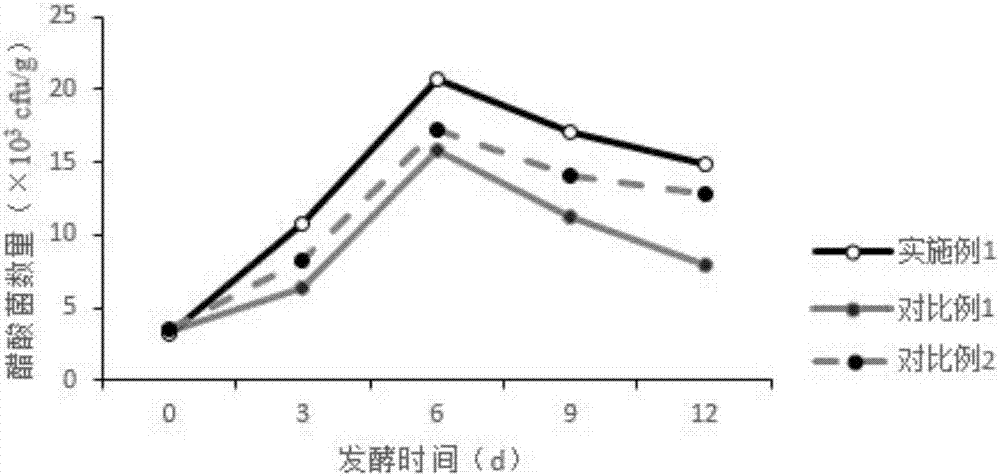

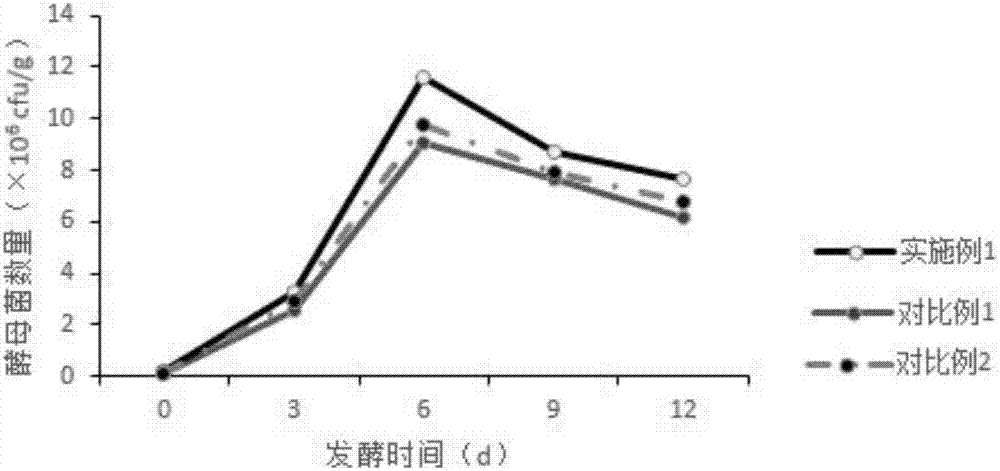

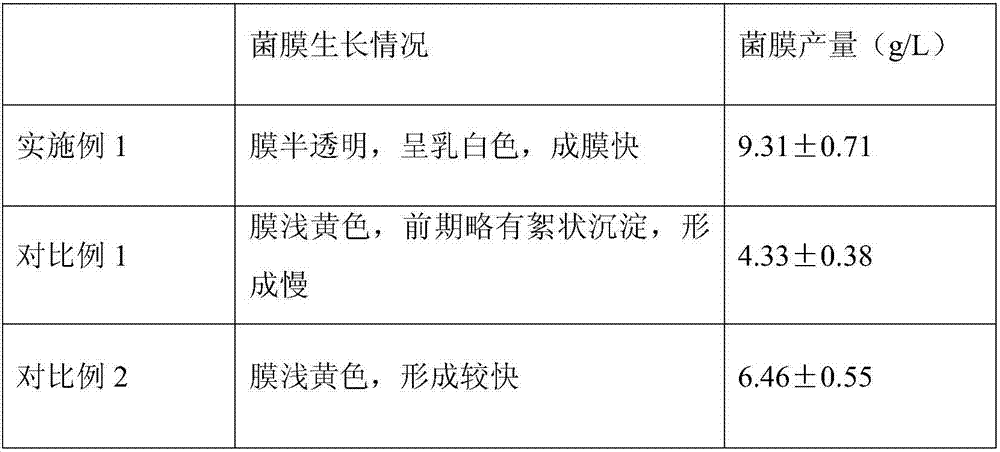

Examples

preparation example Construction

[0013] A preparation method of kombucha bacterial film, comprising the following steps:

[0014] Step 1. Take black tea and extract it with water at 60-90°C twice for 10-30 minutes. The mass ratio of tea leaves to water is 1:(100-200). After primary filtration, mix the two extracts. Using 60-90°C water for two consecutive extractions for 10-30 minutes and then mixing the two extracts can not only obtain black tea extracts with a higher extraction rate, but also effectively reduce the heat-sensitive components in black tea from being destroyed at high temperatures, ensuring Its original flavor.

[0015] Step 2: Add black tea tannase with a mass ratio of 0.05-0.1% to the extract obtained in step 1, then enzymolyze it at 35-45°C for 60-90min, then heat at 90-100°C for 5- 10min to inactivate the enzyme, then cool to room temperature. The polyphenolic compounds in tea not only have strong antioxidant activity, but also have good antibacterial activity, especially ester-type catec...

Embodiment 1

[0025] Take black tea leaves and crush them, extract with pure water at 90°C for 25 minutes at a tea-to-water ratio of 1:150; after coarse filtration, extract the tea dregs at the same tea-to-water ratio for 15 minutes, then filter, and mix the two extracts. After the tea extract is cooled to 45°C, add 0.08% tea leaf weight tannase to the extract, enzymatically hydrolyze for 90 minutes, heat to inactivate the enzyme, and cool to room temperature. Then add 10% sucrose, boil for 10min, and cool to room temperature. Adjust the concentration of the extract to 0.9%, and adjust the pH value to 4.5 with acetic acid. 5% edible ethanol is added in a mass ratio, and bacteria are removed by suction filtration with a 0.45 μm microporous membrane to obtain sterile tea soup. Pack the aseptic tea soup into 1L glass bottles, inoculate the mother liquid of 5% kombucha fungus by volume and 3% kombucha fungus film by mass, then cover the glass bottle with a breathable sealing film and put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com