Method and device for friction stir welding (FSW) assisted by additional heat source

A friction welding and auxiliary stirring technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of high temperature strength limitation of stirring head, high welding cost, low life of stirring head, etc., so as to reduce welding cost and improve The effect of stirring needle life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

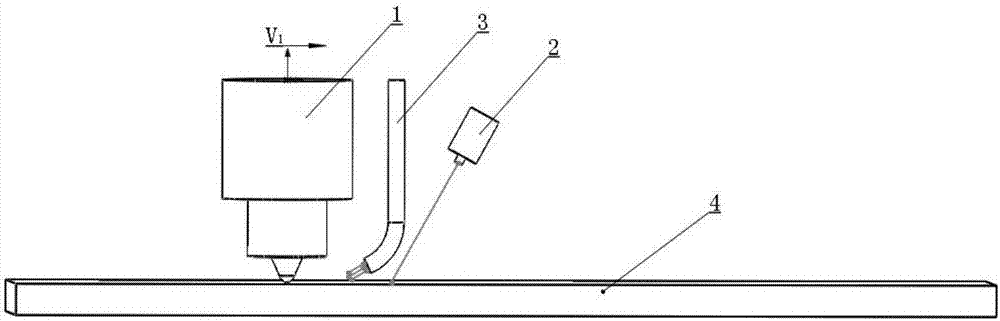

[0056] The additional heat source is laser: the material to be welded is butt joint of No. 45 steel plate with a thickness of 3 mm. Along the welding direction, there are stirring head, gas protection device, and laser beam output focusing lens. The distance between the gas protection nozzle and the edge of the shaft shoulder is 10 mm, along the horizontal direction The included angle is 45°, and the protective gas is argon. The angle that the stirring head deviates from the vertical direction along the welding direction is 2°. When the low-power laser is calibrated, the position where the beam irradiates on the upper surface of the workpiece is the center of the weld seam, the angle between the laser beam and the horizontal direction is 80°, and the laser beam irradiates The connection position of the plate is 2mm away from both ends of the plate, the diameters of the shaft shoulder and the stirring needle are 20mm and 8mm respectively, and the length of the stirring needle is...

Embodiment 2

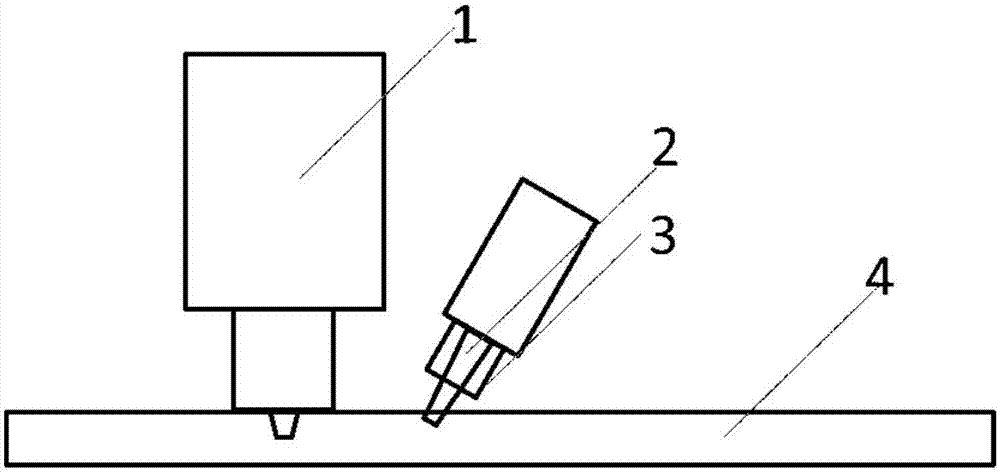

[0058] The additional heat source is electric arc: the material to be welded is 304 stainless steel plate with a thickness of 3mm butt joint, along the welding direction, there are stirring head, TIG arc, and gas protection device in sequence. The distance between the gas protection nozzle and the edge of the shaft shoulder is 10mm, and the angle along the horizontal direction is 45°, and the protective gas is a mixture of argon and helium. The angle at which the stirring head deviates from the vertical direction along the welding direction is 2°. The heating position of the TIG arc on the upper surface of the workpiece is the center of the weld seam. The angle between the TIG arc and the horizontal direction is 85°. Each end is 3mm, the diameter of the shaft shoulder and the stirring needle is 20mm and 8mm respectively, the length of the stirring needle is 2.9mm, during the welding process, the axial downward pressure is 3000kN, the rotation speed of the stirring needle is 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com