A controlled cold deposition 3D printing method for peek materials

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problem of crystallinity of PEEK material that has not been considered, and has not raised the crystallinity of PEEK material, etc., and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] A controlled cold deposition 3D printing method for PEEK materials, comprising the following steps:

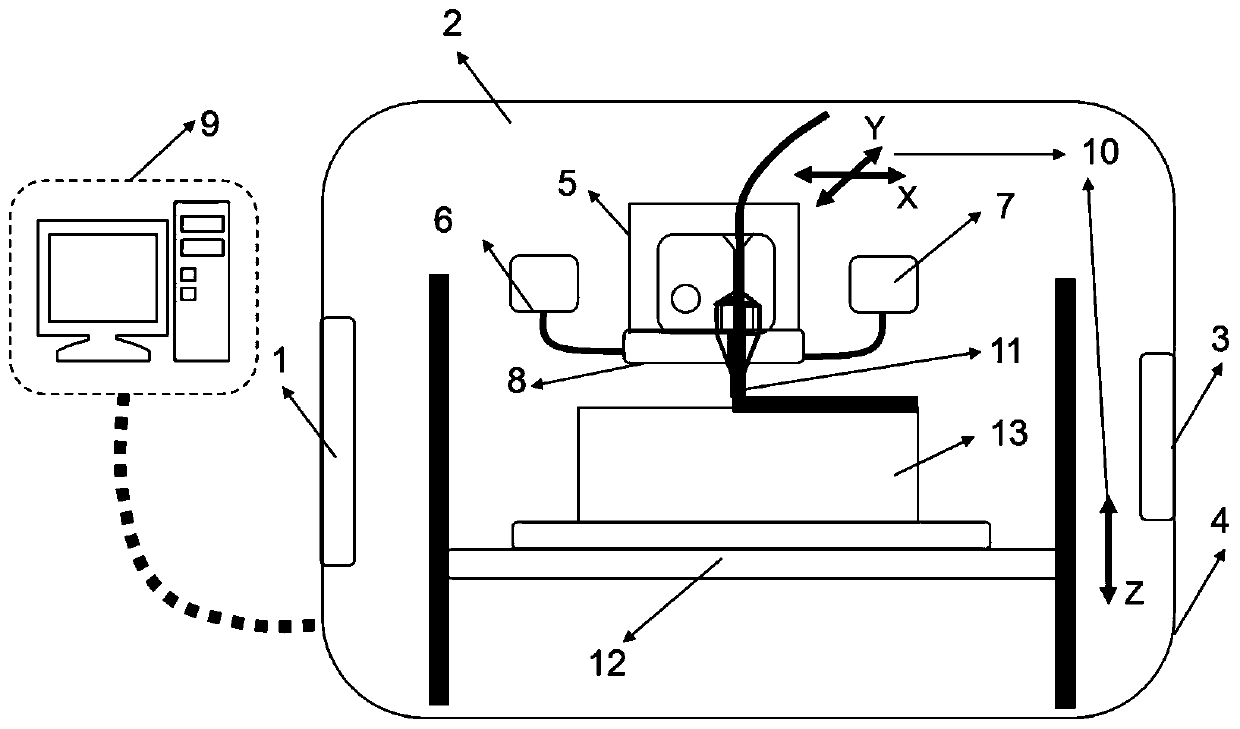

[0019] 1) Refer to figure 1 , the overall temperature control system 1 is used to heat the working cavity 2 of the 3D printer as a whole, and the air circulation system 3 is used to circulate the internal airflow of the working cavity 2 of the 3D printer, and the 3D printer is made to work under the heat preservation effect of the heat preservation system 4 The inner cavity 2 forms the required stable global temperature field;

[0020] 2) Then utilize the local temperature measurement system 6 and the local cooling system 7 on the 3D printing head 5 to cooperate with the local temperature disperser 8 to form a real-time and controllable local rapid cooling field near the 3D printing head 5, and the local cooling system 7 Adopt air cooling, liquid coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com