Anti-fake rare earth luminescent material, preparation method, and application thereof

A rare earth luminescence and rare earth element technology, applied in luminescent materials, chemical instruments and methods, cards for carrying information, etc., can solve the problems of high economic cost of anti-counterfeiting technology, high cost of counterfeiting and copying, and high cost of anti-counterfeiting, and achieve the identification process. Simple and cheap, easy to quickly change and update, simple and diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Tb 0.5 Gd 0.5 (CPBOH)(H 2 O) 2 CPB

[0032] The preparation method of this rare earth luminescent material is as follows:

[0033] In water or alcohol solvent, carboxylic acid phenylboronic acid sodium salt (0.500g, 2.66mmol) and terbium chloride (0.250g, 0.67mmol), gadolinium chloride (0.249g, 0.67mmol) at room temperature in a molar ratio of 2:1 Mix at room temperature, continue to stir and react at room temperature for 0.5 to 12 hours, then filter to collect the solid product; dry at room temperature or under vacuum; obtain 0.351 g of pure product as white solid powder, with a yield of 97%.

[0034] Theoretical element content (%) Tb 0.5 Gd 0.5 C 14 B 2 o 11 h 17 : C, 31.08; H, 3.17; O, 32.53; Measured element content (%): C, 31.07; H, 3.18; O, 32.52. The above analysis results show that the obtained product is the expected product.

[0035] Through the method in Example 1, a series of rare earth luminescent materials can be synthesized, and th...

Embodiment 2

[0036] Example 2: Tb 0.5 Eu 0.5 (CPBOH)(H 2 O) 2 CPB

[0037] In aqueous solution, carboxylic acid phenylboronic acid sodium salt (0.500g, 2.66mmol) was mixed with terbium chloride (0.250g, 0.67mmol), europium chloride (0.245g, 0.67mmol) at room temperature in a molar ratio of 2:1, After continuing to stir and react at room temperature for 0.5-12 hours, the solid product was collected by filtration; dried at room temperature or under vacuum; 0.349 g of pure product was obtained as a white solid powder, with a yield of 98%.

[0038] Theoretical element content (%) Tb 0.5 Eu 0.5 C 14 B 2 o 11 h 17: C, 31.23; H, 3.18; O, 32.69; Measured element content (%): C, 31.24; H, 3.17; O, 32.67. The above analysis results show that the obtained product is the expected product.

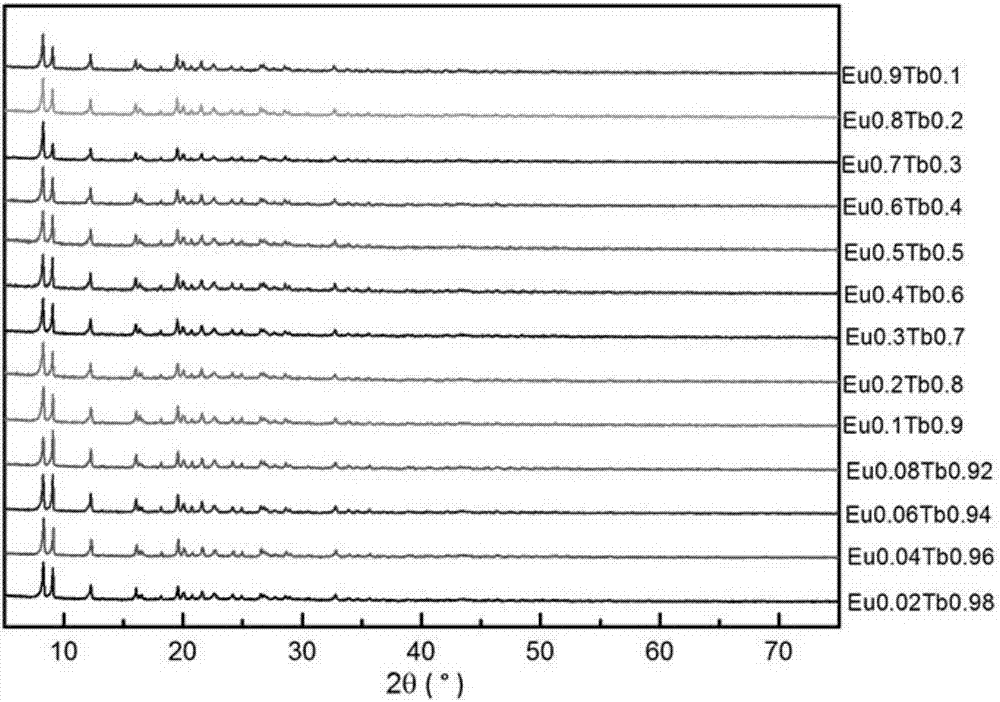

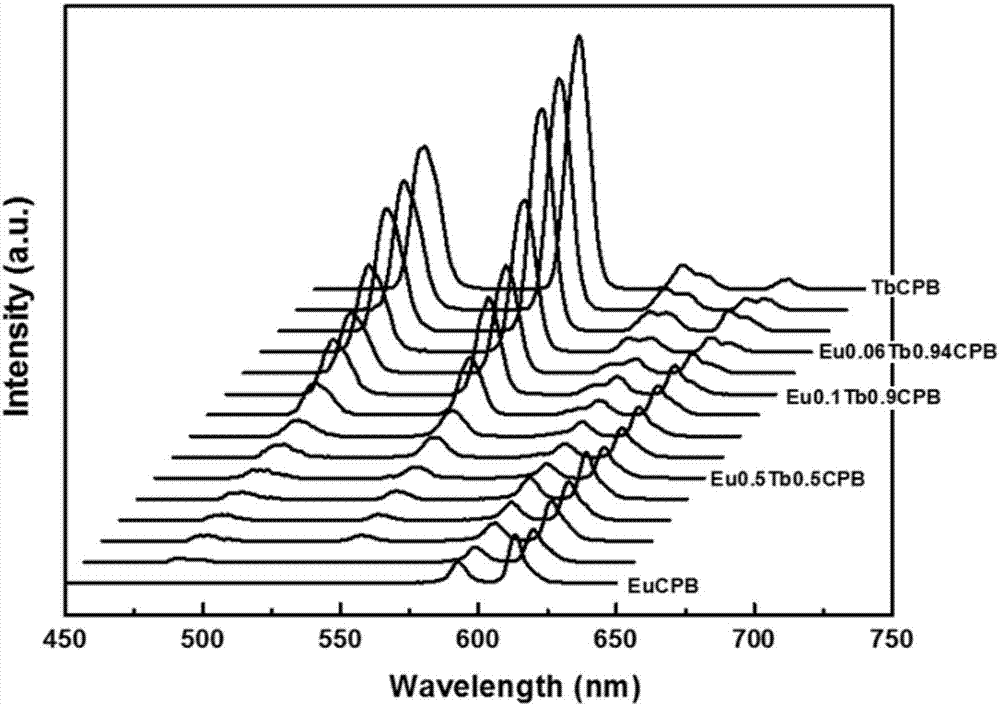

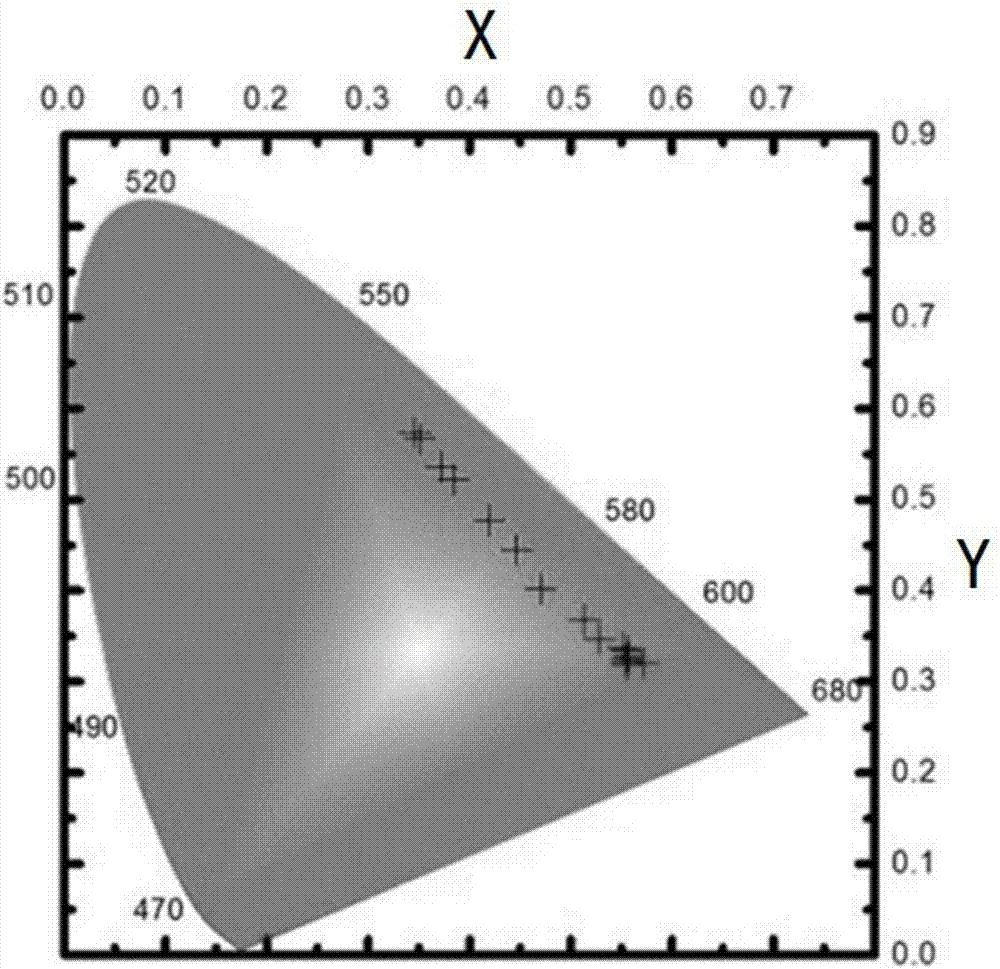

[0039] In addition, this example also synthesized a series of luminescent materials containing Tb and Eu two rare earth metal elements in different proportions, and carried out XRD tests one by one. For ...

Embodiment 3

[0044] Example 3: Eu 0.5 Gd 0.5 (CPBOH)(H 2 O) 2 CPB

[0045] In aqueous solution, carboxylic acid phenylboronic acid sodium salt (0.500g, 2.66mmol) was mixed with europium chloride (0.245g, 0.67mmol), gadolinium chloride (0.249g, 0.67mmol) at room temperature in a molar ratio of 2:1, After continuing to stir and react at room temperature for 0.5-12 hours, the solid product was collected by filtration; dried at room temperature or under vacuum; 0.353 g of pure product was obtained as a white solid powder, with a yield of 98%.

[0046] Theoretical element content (%) Tb 0.5 Eu 0.5 C 14 B 2 o 11 h 17 : C, 31.28; H, 3.19; O, 32.74; Measured element content (%): C, 31.29; H, 3.18; O, 32.76. The above analysis results show that the obtained product is the expected product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com