Graphene EVA-g-MA foam damping material and preparation method of same

A damping material, graphene technology, applied in the field of automotive foam damping materials, can solve the problems of complex manufacturing process, affecting the foaming ratio, reducing product performance, etc., to achieve good product performance, high production efficiency, and increased compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

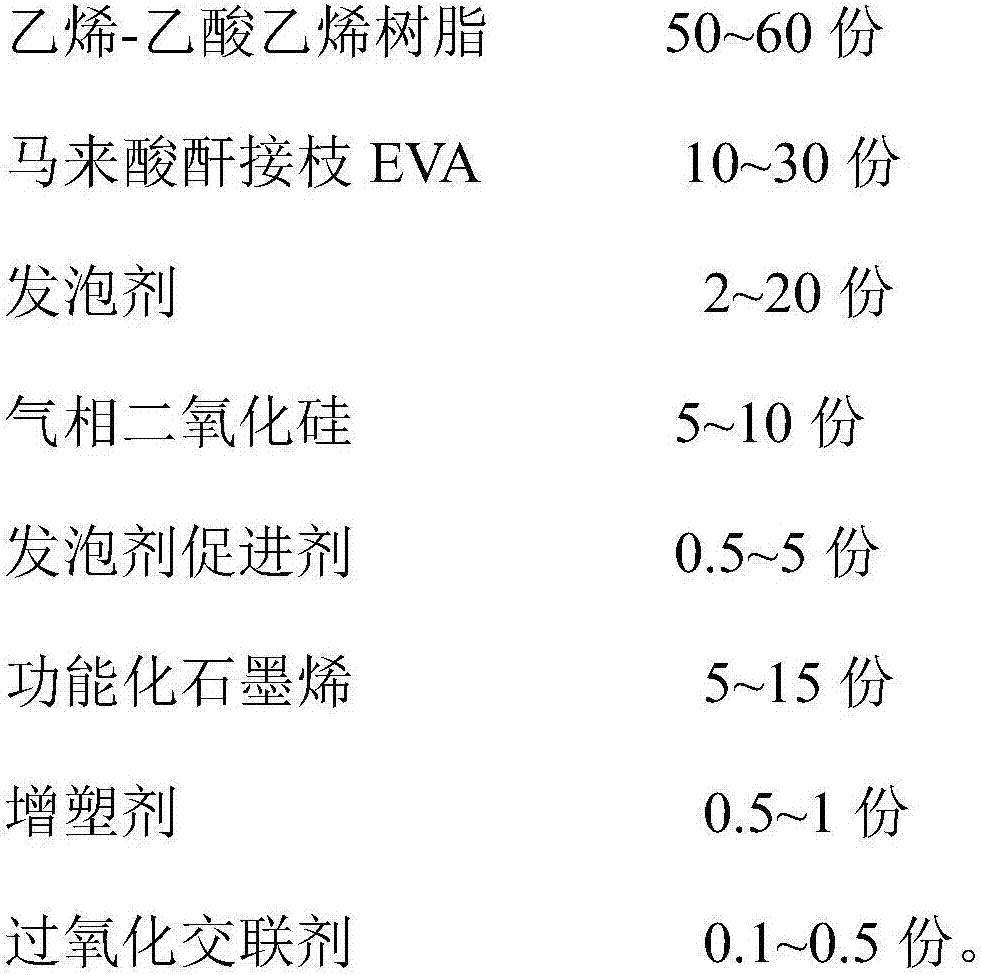

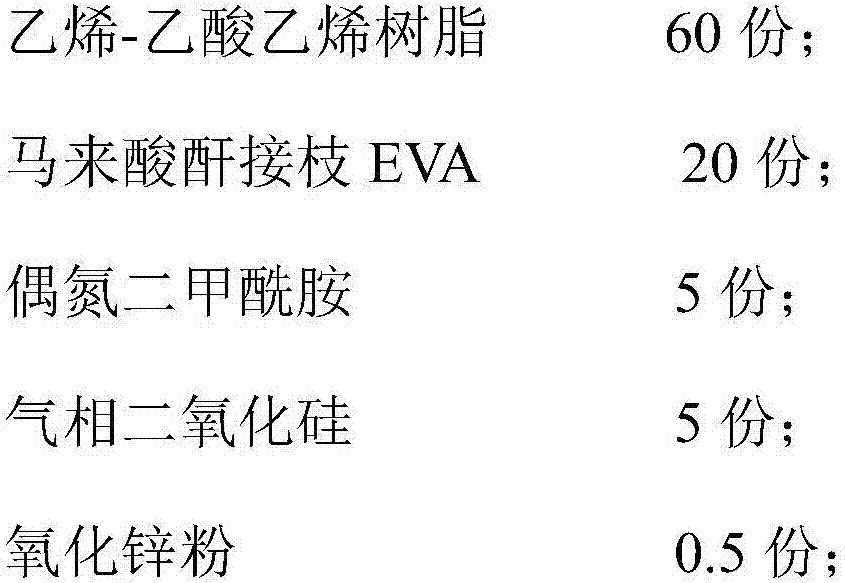

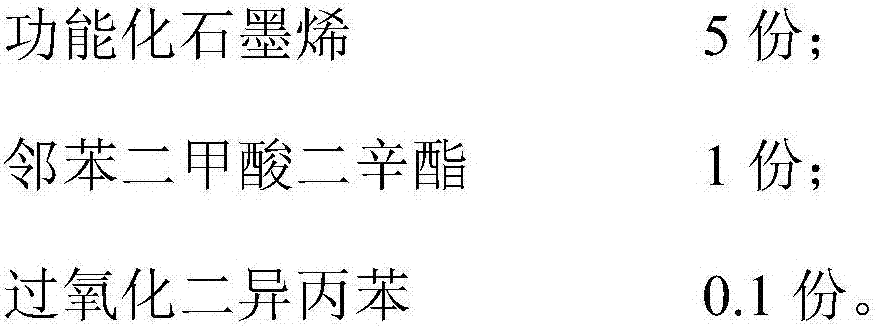

[0030] A composition of graphene EVA-g-MA foam damping material is calculated according to parts by weight:

[0031]

[0032]

[0033] Wherein, the VA amount of the ethylene-vinyl acetate resin is 14wt%;

[0034] Described maleic anhydride grafted EVA graft ratio is 1.5%;

[0035] The preparation method of described functionalized graphene is as follows:

[0036] (1) Using natural graphite powder as raw material, weigh 150-200g of graphite powder into two 2000mL PTFE ball milling tanks, the ball milling time is 240h, the ball milling speed is 500r / min, the ball milling operation mode: alternate, running time After the ball milling is completed with a ratio of 5:1 to the running interval, the obtained solid powder is graphene;

[0037] (2) Take graphene and dissolve it in DMF, ultrasonically disperse, add LiAlH slowly under magnetic stirring, the mass ratio of LiAlH and graphene is 1:4, then add initiator BPO (dibenzoyl peroxide), pass The addition amount of dibenzoyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com